How to Select a Pump for Monomer Dispensing in Contact Lens Manufacturing

Key Takeaways: For monomer dispensing in contact lens manufacturing, Fluid Metering’s valveless piston pumps deliver ±0.5% accuracy and consistent...

2 min read

Stephanie Moreau : Updated on July 22, 2025

In the semiconductor and electronic device manufacturing industries, precision and reliability are paramount. As these industries continue to evolve, the need for advanced tools that can enhance accuracy while supporting high-volume production grows. From cooling systems in microchips to the precise dispensing of chemicals, microfluidic pumps play an essential role in various processes within the semiconductor and electronics sectors. This blog explores the benefits of microfluidic pumps and their transformative impact on manufacturing in these high-tech fields.

1. Unmatched Precision in Fluid Delivery

One of the most significant advantages of Fluid Metering pumps is their ability to deliver fluids in exact, controlled amounts. In semiconductor and electronic device manufacturing, applications often require the handling of minute quantities of liquid with precise control over flow rates. Fluid Metering pumps are designed to operate at micro- and nano-liter scales, enabling manufacturers to achieve exceptionally consistent and accurate fluid delivery. This precision is crucial when dealing with photoresists, etching solutions, and other chemicals used in the fabrication of semiconductors.

For example, in photolithography - a process central to semiconductor manufacturing - the precise application of photoresist chemicals to silicon wafers is critical. Fluid Metering pumps ensure that these chemicals are evenly and accurately dispensed, which helps to create consistent patterns on the wafer surface.

2. Compact Design

Space is at a premium in semiconductor manufacturing facilities, where cleanrooms are densely packed with equipment. The small size of Fluid Metering pumps is a significant advantage in such environments, allowing them to be easily integrated into existing manufacturing setups without requiring additional space. Their compact form factor also makes them ideal for applications in cooling systems within densely packed devices, such as microprocessors and high-power electronics.

3. Extended Equipment Longevity and Reduced Maintenance

Fluid Metering pumps have fewer moving parts than traditional pumps, which lowers the likelihood of mechanical failure and extends their operational life.

Because Fluid Metering pumps are built to be reliable and low maintenance, they require less frequent servicing, which reduces downtime. Manufacturers benefit from increased equipment longevity and improved process continuity, ultimately leading to higher productivity and lower maintenance costs.

4. Improved Thermal Management in Electronic Devices

As electronic devices become smaller and more powerful, the need for effective thermal management has grown. Fluid Metering pumps play a critical role in managing heat within microelectronic devices, such as processors and high-power transistors. In such applications, Fluid Metering pumps can circulate coolant through tiny channels, removing excess heat from the device and ensuring stable performance. This efficient thermal management extends the lifespan of electronic components, enhances device reliability, and improves energy efficiency, which is especially vital in high-performance computing and power electronics.

Conclusion

In semiconductor and electronic device manufacturing, Fluid Metering pumps provide a valuable combination of precision, efficiency, and adaptability. Their ability to deliver fluids in precise quantities, support automation, and reduce maintenance makes them an ideal choice for today’s high-tech manufacturing needs. Fluid Metering pumps help manufacturers address the increasingly complex challenges associated with producing smaller, faster, and more efficient devices. As the demand for precision in manufacturing grows, Fluid Metering pumps will undoubtedly continue to play a pivotal role in driving innovation and efficiency in the semiconductor and electronics industries.

Key Takeaways: For monomer dispensing in contact lens manufacturing, Fluid Metering’s valveless piston pumps deliver ±0.5% accuracy and consistent...

1 min read

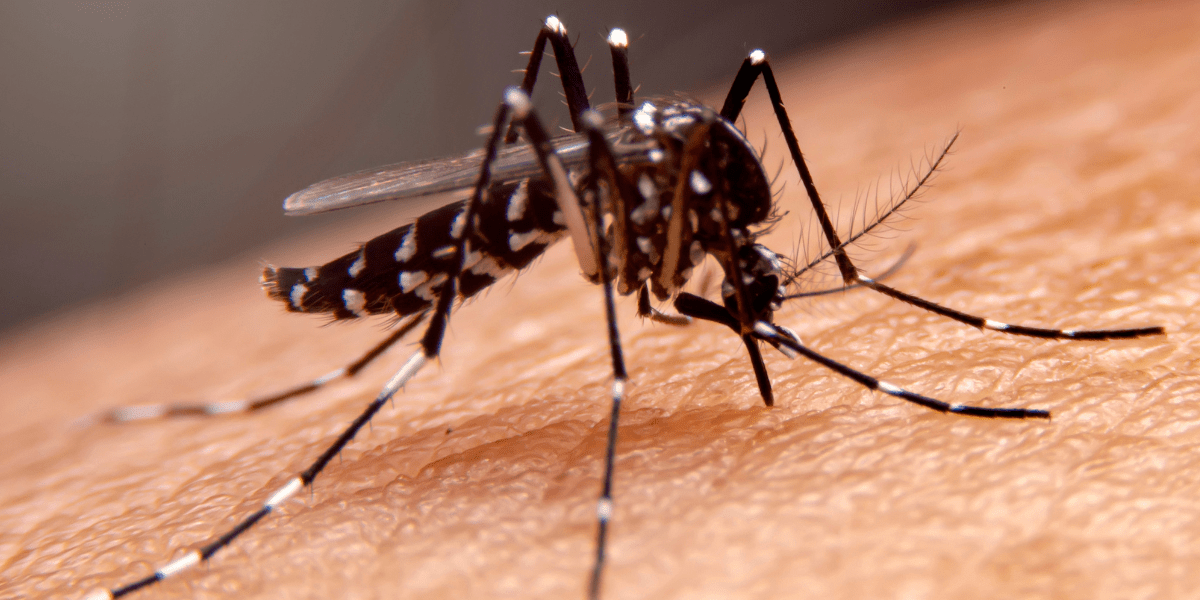

Key Takeaways: In ULV mosquito fogger pump systems, durability, repeatability, and chemical compatibility are critical—Fluid Metering’s ceramic...

1 min read

Key Takeaways: Atomization transforms liquids into fine droplets for enhanced surface area, enabling precise sterilization, coating, and...