Life at Fluid Metering

Ready to join a collaborative work environment?

Where Every Employee Matters!

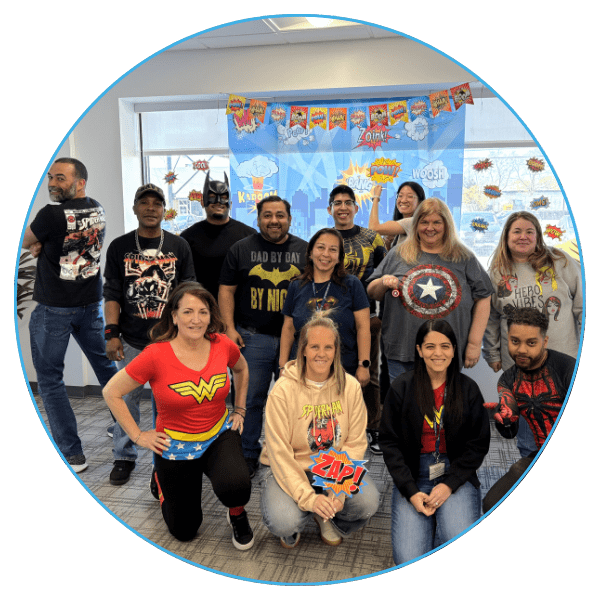

At Fluid Metering, our culture and beliefs are built on Collaboration, Mutual Respect, Diversity, and Integrity. We focus on strengthening our team's individual development, and are proud of our culture of Collaboration, Performance Excellence, and Accountability.

We empower our team by creating an environment that fosters their entrepreneurial spirit through innovation. We believe in, and continually invest in, talent development, and providing team members with ongoing opportunities to learn and benefit from our growth.

Who We Are

Vision

To be the leader in breakthrough technologies providing go-to solutions for the world’s most demanding fluidic challenges.

Mission

Through innovation, we unlock next generation fluidic applications that enables advancements for life science and industrial partners.

Our Core Values

Collaborative Workplace

Best in Class Products

Customer Success

I enjoy my job and what I do, as I've gained new skills and insights that will benefit me beyond work.

I have many reasons that I like to work at Fluid Metering! We celebrate as a Team our wins and work together to resolve any concerns or issues that arise along the way. As an individual my opinion matters and my voice counts. You are always encouraged to participate and grow within the company.

I joined Fluid Metering four years ago and there are many reasons I love working here, but my biggest reason is the people. Fluid Metering fosters an environment of kindness and gratitude and that is apparent in the people you interact with every day. I can always count on my colleagues to offer help when needed and to be appreciative of the help that is offered to them. It feels great to know that we are all in this together and to feel valued for all our hard work.

Working at Fluid Metering means being part of a team that values quality and precision. The opportunity to work on groundbreaking projects is one of the many reasons I love my job here. I value the open communication and transparency that Fluid Metering promotes with the team.

I couldn’t imagine a better place to work! Our contributions are highly valued, and the entire organization thrives on collaboration between all departments. The leadership team is genuinely invested in employee growth, offering numerous opportunities for professional development. It’s the perfect blend of a supportive and forward-thinking workplace.

Core Cultural Values

Collaboration

- We work together with key internal and external stakeholders to achieve mutually beneficial solutions by sharing knowledge and building consensus.

Diversity

- We support a broad perspective of thought and inclusion, and represent needs from internal and external stakeholders and partners.

Integrity

- We continually build an open, honest, and caring environment that inspires trust with customers, partners, and peers, while striving for excellence in team performance and quality.

Social Responsibility

- We support our community by sponsoring annual events, including clothing, food, pet supplies, and toy drives, as well as hosting events to raise awareness for heart health and breast cancer prevention.

Benefits

-

Medical

Choice of two medical plans - traditional PPO, and High-Deductible Health Plan with a company funded Health Savings Account.

-

Dental

Participants may take advantage of reduced out-of-pocket costs when they use dentists in a nationwide network of participating providers. Our dental plan pays for preventive, restorative and surgical services, as well as orthodontia, at varying levels of coverage.

-

Vision

Low-cost plan to support in maintaining eye health, with discounts on eyewear and in-network providers.

-

Flexible Spending

Health and Dependent Care Flexible Spending Accounts provide the opportunity to set aside money on a pre-tax basis for eligible out-of-pocket expenses.

-

Employee Assistance Program

Provides immediate and confidential support for work, health, or life concerns. Available 24/7.

-

Retirement

Profit Sharing and 401(k) matching contributions, immediately vested.

-

Perks

- 4 ½ day work week (40 hours per week)

- 11+ paid holidays

- 3 Weeks’ Vacation*

- 3 Personal Days*

- Sick Days*

- Employee Engagement and Team Building Events

- Individual Development Plans to provide opportunities for growth

*Vacation, Personal, and Sick Days are pro-rated in year one

Open Positions

Mechanical Engineer - Long Island, New York

To be considered, or inquire about one of our opportunities, email recruiting@fluidmetering.com.

Disclaimer

Fluid Metering, Inc. is an equal opportunity employer and strongly supports diversity in the workplace. We believe that diverse ideas, opinions, and perspectives will build a strong foundation for success. In order to provide equal employment and advancement opportunities to all individuals, employment decisions at Fluid Metering, Inc. will be based on merit, qualifications, and abilities. Fluid Metering, Inc. does not discriminate in employment opportunities or practices on the basis of race, color, religion, sex, national origin, age, disability, or any other characteristic protected by law.

The salary range displayed is the minimum and maximum salary range for this role, at the time of the position posting. Actual compensation for this role will be based on a number of different factors including but not limited to the candidate’s knowledge, skills, experience, and education.

Fluid Metering offers a competitive total rewards package which includes immediate healthcare, life insurance, profit sharing, paid time off, profit sharing and 401(k) match with immediate vesting, and other voluntary benefits.

Alert:

- All communication regarding this opportunity will come directly from a verified Fluid Metering, Inc. recruiter either by a Fluid Metering email address, or via the posting source.

- Our recruiting process will include in-person and/or video interviews.

- We never request payment, bank information, or personal financial details during our offer process.

Equal Opportunity Employer/Protected Veterans/Individuals with Disabilities