1 min read

Pump Up Your Precision: Fluid Metering vs. Centrifugal Pumps

Key Takeaways: For precision fluid metering vs. centrifugal pumps, Fluid Metering’s valveless piston pumps offer unmatched accuracy, chemical...

2 min read

Stephanie Moreau : Updated on July 22, 2025

Industrial, environmental, and medical devices use pumps for various functions in many of their applications. Among the myriad of pump types available, piston pumps and peristaltic pumps are often compared due to their distinctive mechanisms and suitability for various tasks. Here, we'll explore the advantages of Fluid Metering valveless piston pumps over peristaltic pumps and why their low maintenance and repeatability make Fluid Metering pumps the preferred choice.

Precision and Accuracy

One of the most significant advantages of Fluid Metering piston pumps is their precision. Known for their ability to deliver fluids with exceptional accuracy and consistency, their precision is particularly important in applications where even slight variations in fluid delivery can have substantial consequences, such as in medical dosing or chemical processing. On the other hand, the constant squeezing and releasing of the peristaltic pump tubing reduces its accuracy over time and increases pulsation, which makes it unsuitable for certain applications.

High Pressure Capabilities

Fluid Metering pumps are capable of generating much higher pressures compared to peristaltic pumps. This makes them ideal for applications that require high-pressure delivery, such as hydraulic systems and high-pressure cleaning. Unlike the robust design of piston pumps that allows them to handle these demanding tasks without compromising performance, peristaltic pump designs limit their maximum flow rate capabilities.

Durability and Longevity

Due to their sturdy construction and fewer moving parts, Fluid Metering’s valveless piston pumps generally offer greater durability and a longer lifespan than peristaltic pumps. The materials used in Fluid Metering piston pumps are often chosen for their ability to withstand harsh conditions and abrasive fluids, making them a reliable choice for long-term use in medical settings. Due to the pressures and wear on peristaltic pump tubes, they often require replacement anywhere from a few hundred hours to several thousand hours of operation.

Versatility in Fluid Handling

Fluid Metering piston pumps can handle a wide range of fluids, including those with varying viscosities and abrasive particles. This versatility makes them suitable for diverse applications. On the other hand, peristaltic pumps may struggle with highly viscous fluids or those containing solid particles, limiting their applicability.

Efficiency and Performance

The efficiency of piston pumps is another compelling advantage. These pumps are designed to minimize energy loss and maximize fluid delivery efficiency. This not only leads to cost savings over time but also ensures consistent performance even under varying operating conditions. Peristaltic pumps, while effective in certain scenarios, often require higher energy consumption and experience reduced efficiency due to the friction between the tube and rollers.

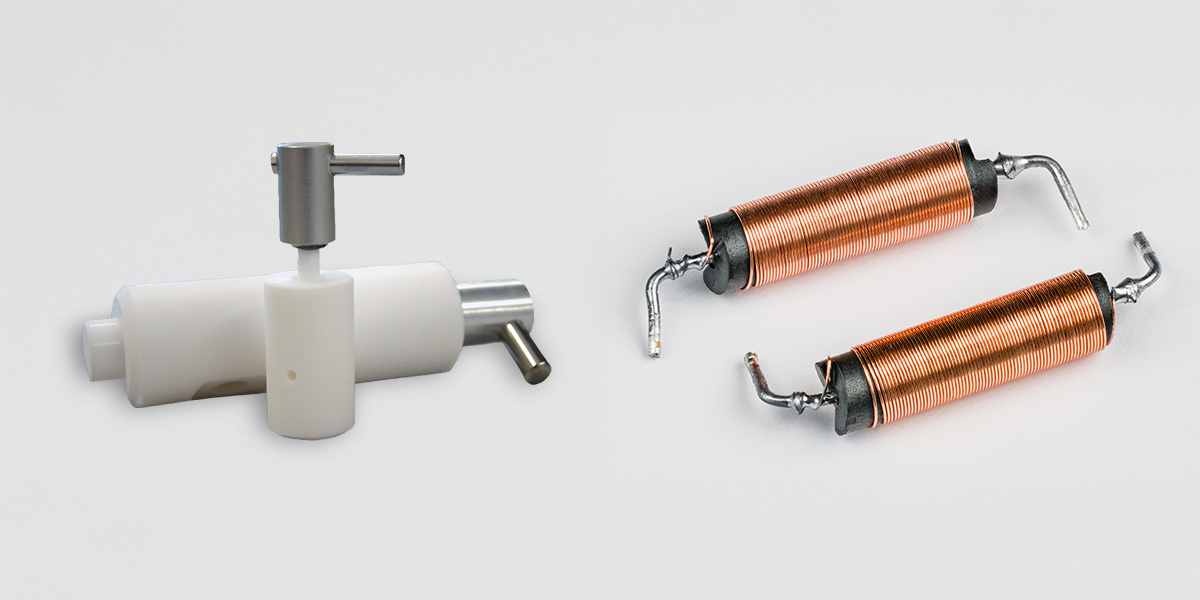

Reduced Maintenance

Fluid Metering piston pumps typically require less frequent maintenance compared to peristaltic pumps. The design of Fluid Metering piston pumps reduces the wear and tear on components, leading to fewer breakdowns and less downtime. In contrast, the constant compression of the tubing in peristaltic pumps (image right) can cause them to degrade over time, demanding regular replacement and increasing maintenance efforts.

Conclusion

While both Fluid Metering valveless piston pumps and peristaltic pumps have their place in fluid handling, the advantages of piston pumps make them a superior choice for many demanding applications. Fluid Metering engineers have been designing and manufacturing reliable high precision pumps for over 60 years. Their precision, high-pressure capabilities, durability, versatility, efficiency, and reduced maintenance requirements position them as the preferred solution for industries that demand reliable and consistent fluid delivery.

1 min read

Key Takeaways: For precision fluid metering vs. centrifugal pumps, Fluid Metering’s valveless piston pumps offer unmatched accuracy, chemical...

Key Takeaways: For precision fluid delivery vs. solenoid pumps, Fluid Metering’s valveless piston pumps outperform in accuracy, reliability, and...

Key Takeaways: For valveless piston pumps vs. diaphragm pumps, Fluid Metering’s CeramPump® technology offers superior precision, clog resistance,...