1 min read

Sound Solutions to Reduce Noise in Microfluidic Pumps

Key Takeaways: In low-noise microfluidic pump applications, such as home dialysis or dental devices, reducing vibration and acoustic output is...

2 min read

Colin Rademacher : Updated on July 22, 2025

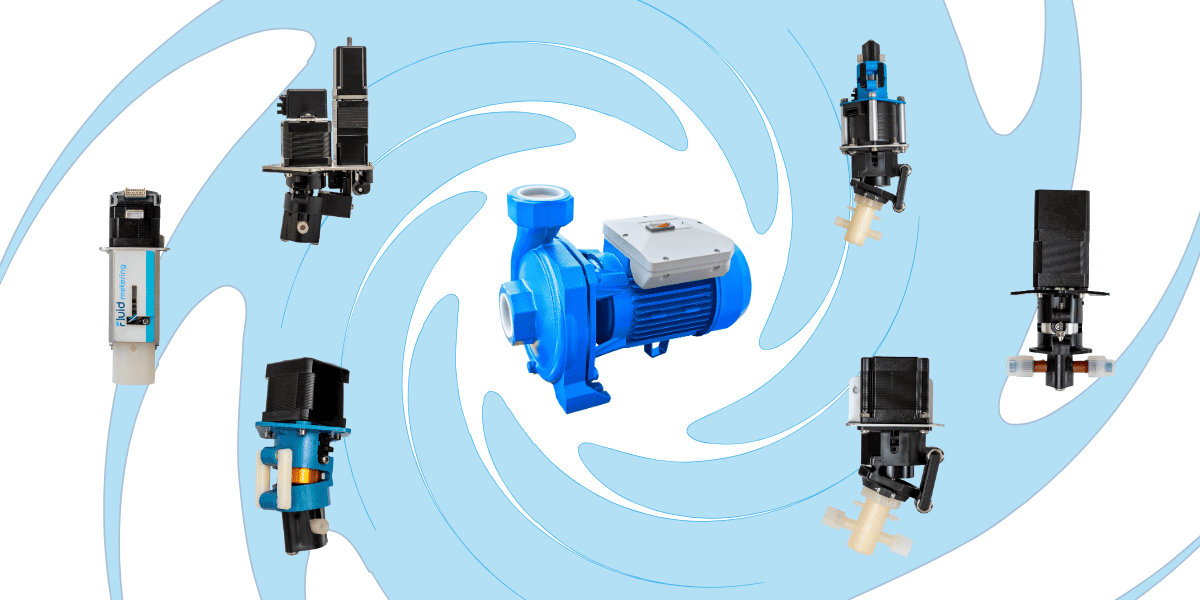

In the life sciences industry, precision and reliability are paramount. Fluid Metering understands this, and that's why we offer world-class pumps that don’t require valves. Our reciprocating piston pumps are specifically designed to eliminate a critical threat to IVD, genomic, instruments, and dialysis machines: cavitation.

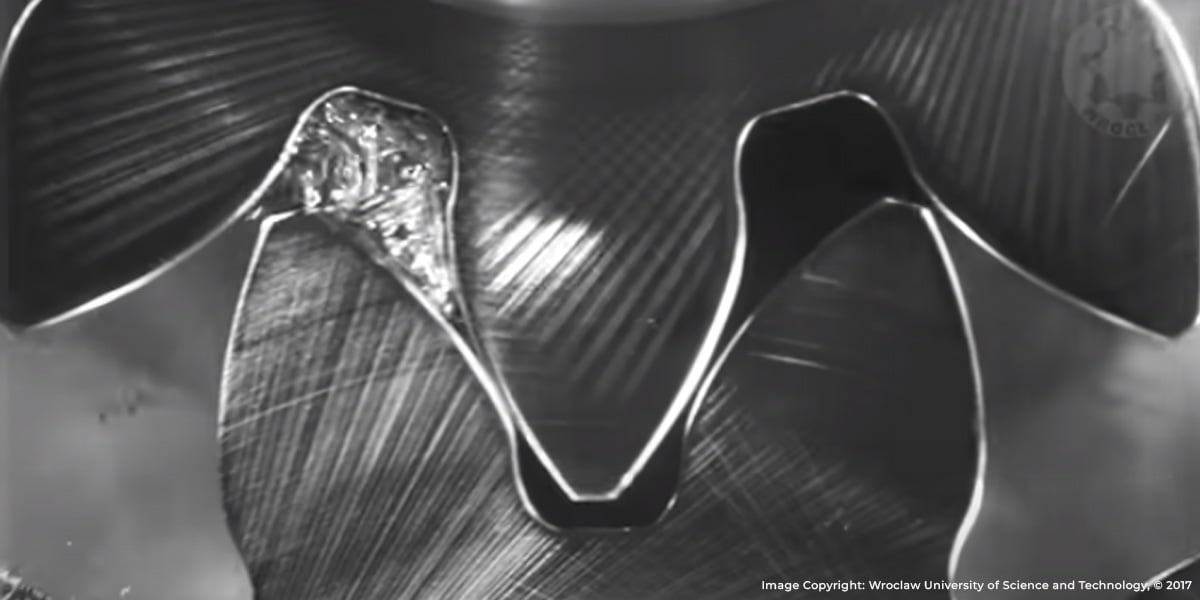

Above Video Copyright: Wroclaw University of Science and Technology, © 2017

Why Cavitation Matters in Life Sciences:

Cavitation is the formation and violent collapse of vapor bubbles within a liquid, creating unfilled voids and unwanted movement. This phenomenon wreaks havoc in life science applications:

The Gear Pump Conundrum:

Traditional gear pumps, a mainstay for many years, introduce a significant risk of cavitation. Their inherent design (gears with voids between them) creates localized pressure drops. Since most gear pumps require check valves, bigger filters, more fittings, and thus more tubing, it adds to the pressure drop, resulting in more cavitation.

The Valveless Piston Pump Advantage:

Fluid Metering's valveless piston pumps address these concerns head-on. Unlike gear pumps, our design requires fewer components, allowing for simplified fluidics architecture. Removing valves, gears, and alternate complex components eliminates voids, preventing the pressure drops that trigger cavitation. This translates to:

Investing in Reliability:

By choosing Fluid Metering's valveless piston pumps, OEMs in the life sciences gain a crucial edge. Our pumps ensure the consistent, reliable fluid flow critical for accurate diagnostics and efficient operations. This lends to cost savings for labs and hospitals, ultimately enabling OEMs to gain a competitive advantage against their competition.

Contact Fluid Metering today to learn how our innovative pumps can elevate your life science equipment to a new level of performance and reliability.

1 min read

Key Takeaways: In low-noise microfluidic pump applications, such as home dialysis or dental devices, reducing vibration and acoustic output is...

1 min read

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

1 min read

Key Takeaways: For precision fluid metering vs. centrifugal pumps, Fluid Metering’s valveless piston pumps offer unmatched accuracy, chemical...