A Guide to Low-Maintenance Microfluidic Pumps

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

2 min read

Mark Tintera : Updated on July 22, 2025

Sometimes noise can be a significant issue in microfluidic pumps, affecting both performance and user experience, especially in sensitive environments like home-based applications. We’ve listened intently to find some of the most common sources of noise in microfluidic pumps and have sounded (and of course, responded to) the call for practical noise reduction solutions!

Applications Requiring Noise Reduction

You may be thinking, “Why would it matter how loud the pump is?” There are several instances where noise reduction is heavily desired. These include:

Sources & Identification

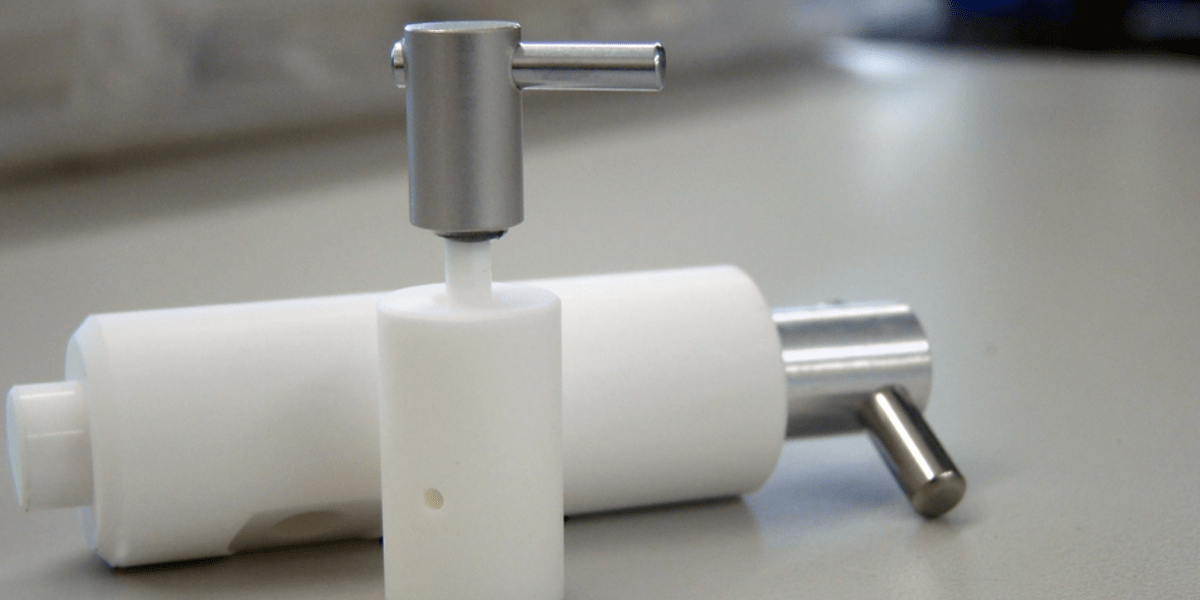

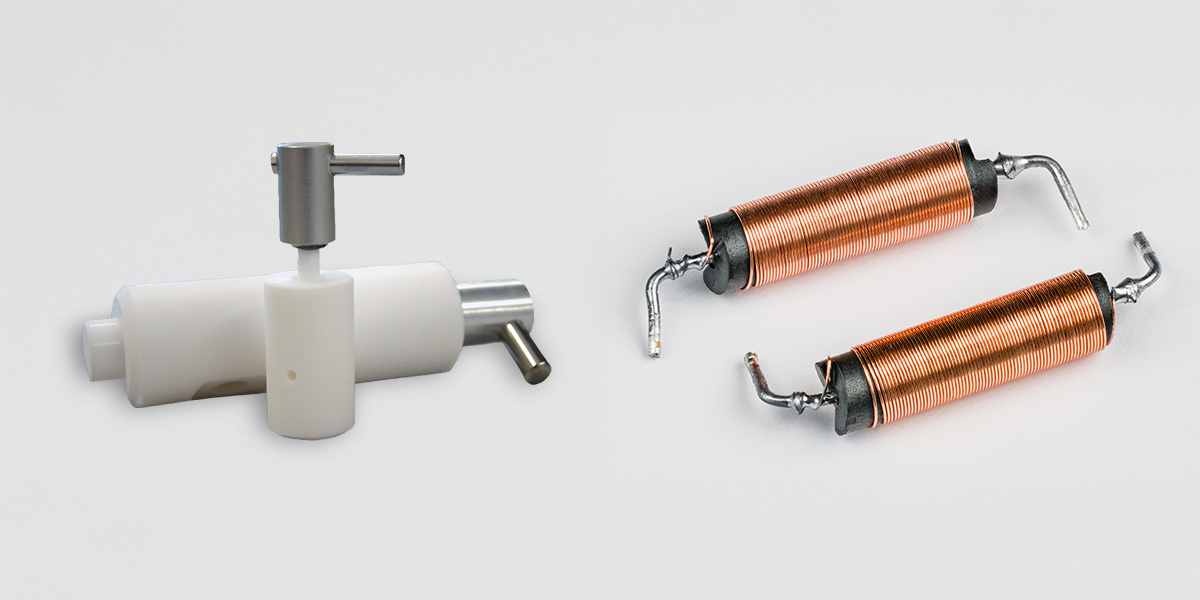

Noise in microfluidic pumps can originate from several common sources including the motor, pump head, fluid movement through the pump and its tubing, pulsations, and overall mechanical system vibrations. If you’re not sure where the sound is being generated from, the best way to find it is through process of elimination:

Does Material Selection Play a Role? Although flexible materials tend to better absorb vibrations, the speed and flow rate of the pump will contribute far more to noise production than the materials used. While slower running systems will remain relatively quiet, faster speeds and flow rates can cause a bit of a ruckus.

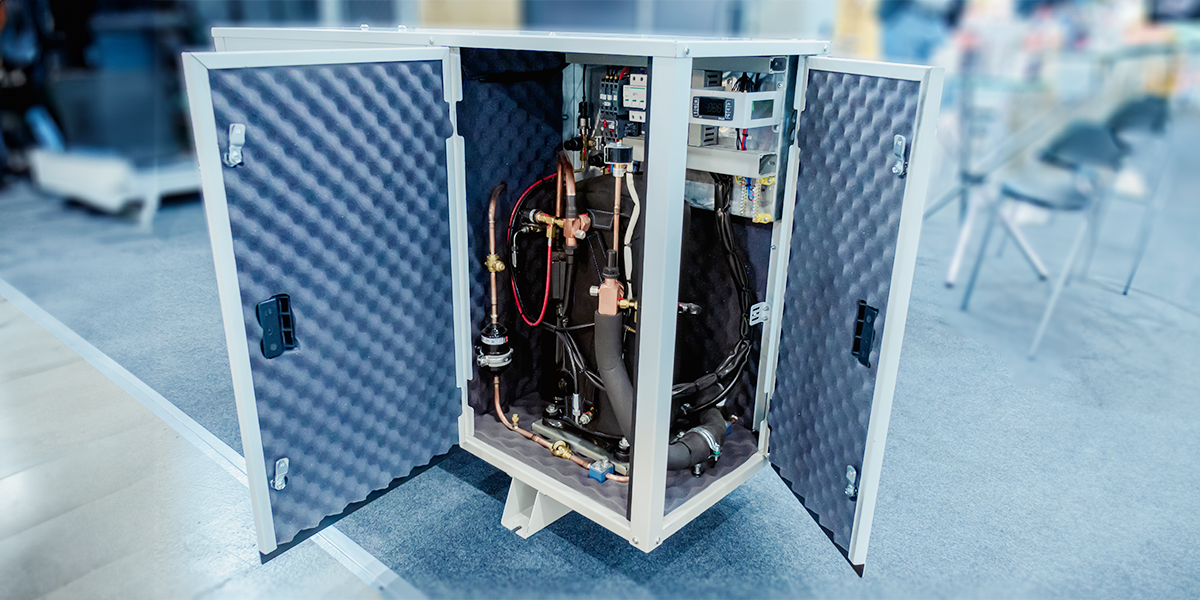

Vibration and Noise Mitigation

The best practices for mitigating vibrations are:

Hear to Help

By understanding the sources of noise and implementing the above strategies, users can significantly reduce noise levels in microfluidic pumps, enhancing both performance and customer experience. However, if you still need help locating or rectifying the noise of your pump system, we’re all ears! Users can send videos with audio to our team for accurate diagnosis and troubleshooting support. Contact us today to voice your noise concerns with us.

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

Key Takeaways: For precision fluid delivery vs. solenoid pumps, Fluid Metering’s valveless piston pumps outperform in accuracy, reliability, and...

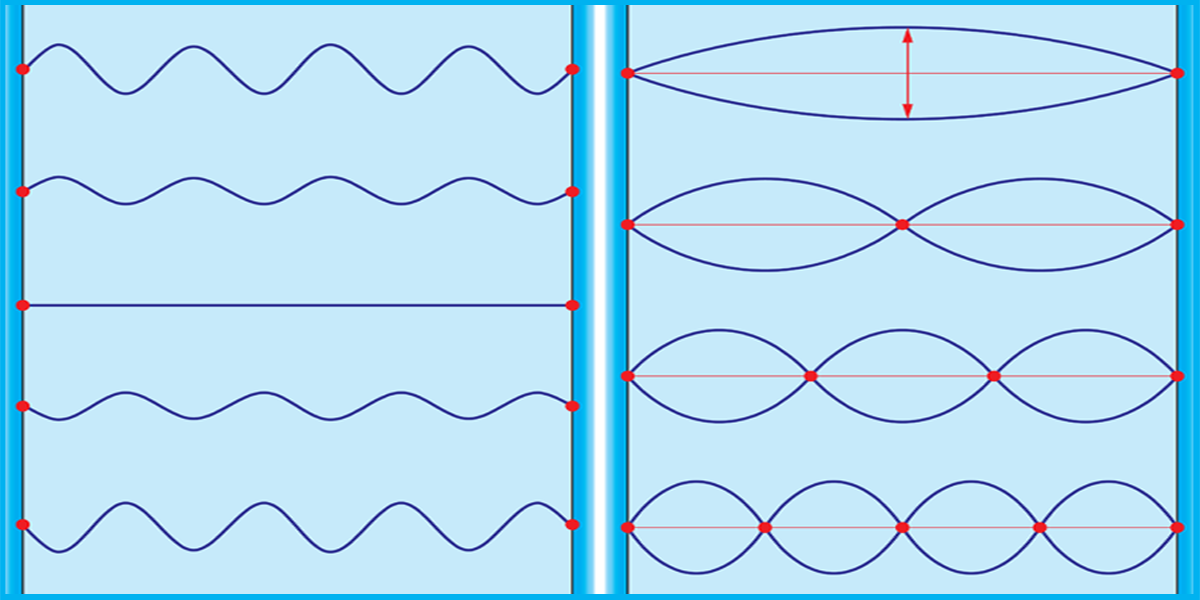

Key Takeaways: In microfluidic pump systems, pulsation refers to periodic flow rate fluctuations that can impact accuracy, stability, and...