1 min read

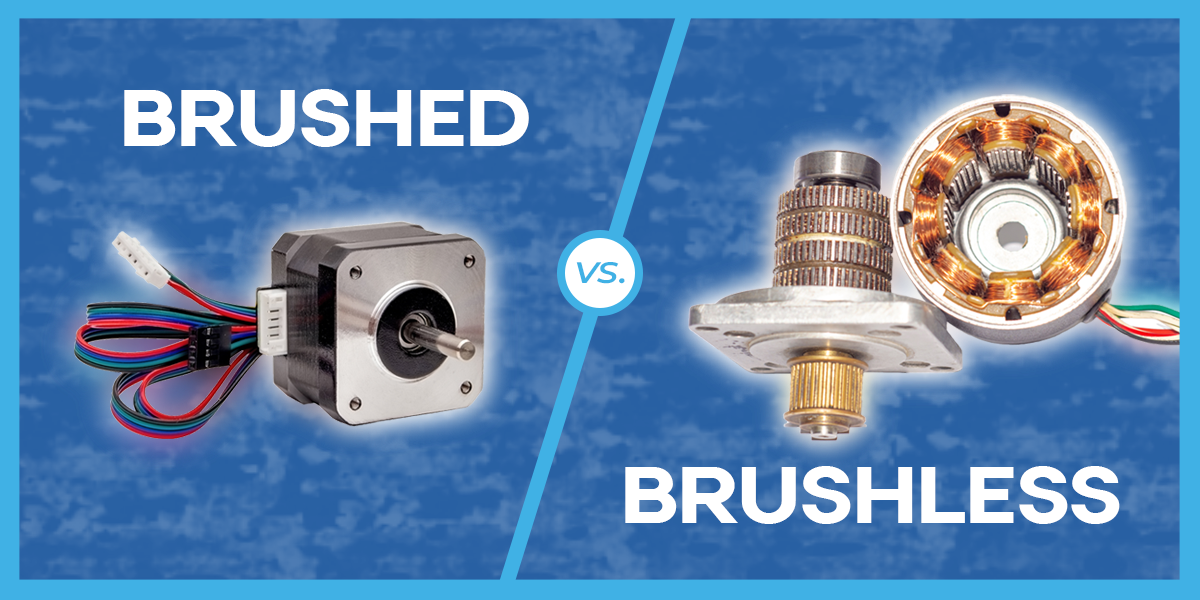

Brushed vs. Brushless Motors: Technical Comparison

Key Takeaways: In microfluidic systems, brushless motors for precision dispensing offer superior control, efficiency, and lifespan compared to...

2 min read

Stephanie Moreau : Updated on July 22, 2025

In the dynamic world of electronics and instrumentation, selecting the right electrical interface is crucial for optimal performance. Additionally, when it comes to controlling stepper motors, a fundamental understanding of the requirements is essential. In this blog post, we will delve into the considerations for choosing the best electrical interface for your instrument and explore the necessities for effective stepper motor control.

Choosing the Right Electrical Interface

Compatibility:

When selecting an electrical interface for your instrument, compatibility is key. Ensure that the interface aligns with the specifications of your instrument and can seamlessly integrate with other components in your system.

Power Requirements:

Assess the power requirements of your instrument and choose an electrical interface that can provide the necessary power. USB interfaces often provide both data transfer and power, simplifying the overall design by reducing the need for additional power sources.

Noise Immunity:

In environments where electrical noise is a concern, opt for interfaces that offer good noise immunity. This is particularly important for instruments operating in industrial settings or other environments where electromagnetic interference may be present.

Understanding Stepper Motor Control

Drive Electronics:

To control a stepper motor effectively, you need appropriate drive electronics. Stepper motor drivers convert control signals into precise movements. The type of drive electronics you choose depends on factors such as the motor's specifications and the desired level of precision.

Microcontroller or Microprocessor:

A microcontroller or microprocessor serves as the brain of your stepper motor control system. It interprets commands, processes data, and sends signals to the drive electronics. Select a microcontroller with sufficient processing power and the ability to interface with your chosen electrical interface.

Control Algorithm:

Implementing the right control algorithm is crucial for smooth stepper motor operation. Common algorithms include open-loop control for simpler applications and closed-loop control for more demanding tasks that require accurate positioning.

Feedback Systems:

For precise control and feedback, consider integrating feedback systems such as encoders or sensors. These systems provide real-time information about the motor's position, allowing for adjustments and corrections as needed.

Conclusion

Choosing the best electrical interface for your instrument and understanding the requirements for stepper motor control are essential steps in creating a reliable and efficient system. By carefully considering factors such as compatibility, power requirements, noise immunity, and cost, you can make informed decisions that lead to the successful integration of these components in your application. Fluid Metering engineers have years of stepper motor experience and can help guide you in choosing the best electrical interface for your instrument.

1 min read

Key Takeaways: In microfluidic systems, brushless motors for precision dispensing offer superior control, efficiency, and lifespan compared to...

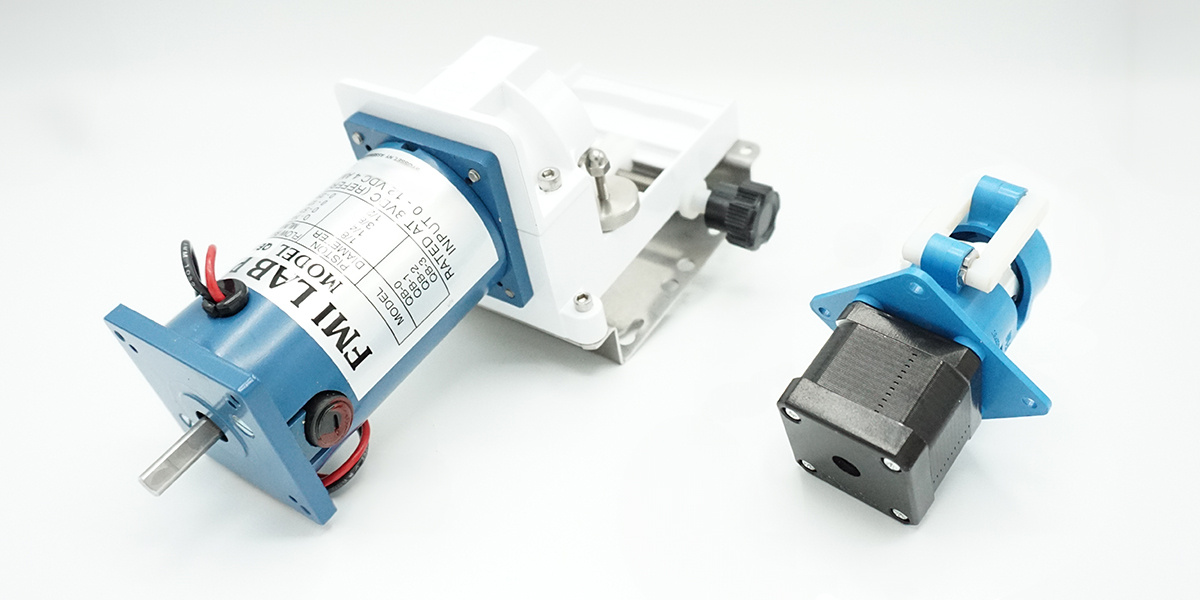

Key Takeaways: For motor control in fluidic pump systems, selecting between stepper and DC motors impacts flow precision, torque, and...

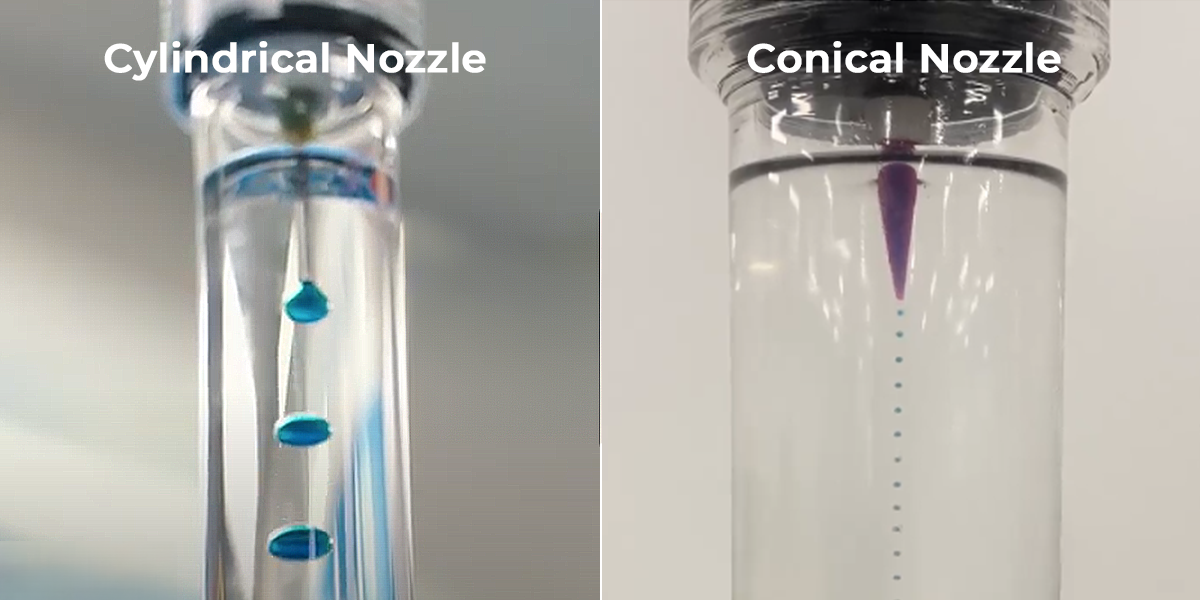

Key Takeaways: For microfluidic nozzle sizing and shape optimization, selecting between cylindrical and conical tips impacts bubble removal,...