Controlling Instrument Options in Fluidic Pump Systems: Why It Matters

Key Takeaways: For motor control in fluidic pump systems, selecting between stepper and DC motors impacts flow precision, torque, and...

2 min read

Richard Hill : Updated on July 22, 2025

Just as selecting the proper microfluidic pump plays a pivotal role in diagnostics, semiconductors, agriculture, and other industries, so does selecting the proper nozzle size and shape. These nozzle properties can affect various aspects of each application from general operational function and safety to fine tuning the best possible results. Let's tap into why nozzle sizing and shape are important to consider in your decision-making process.

Nozzle Shape Advantages

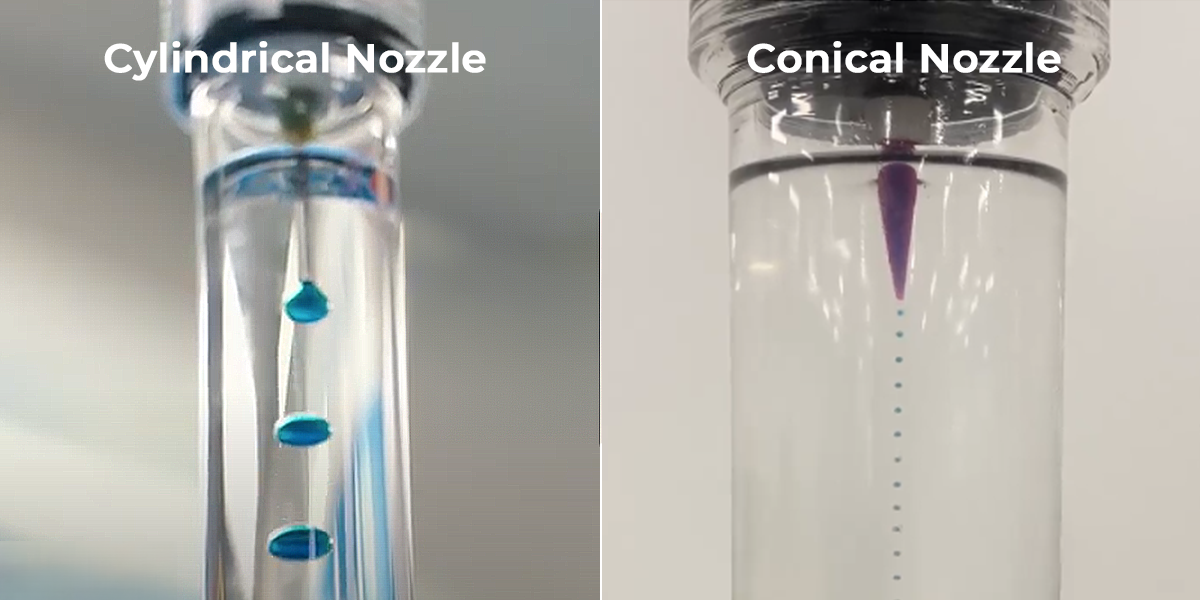

Two main nozzle shapes are used in microfluidics: the hollow cylinder and the hollow conical shape (as seen above). While the cylinder has a consistent inner diameter, which is more effective at flushing out bubbles, this comes at the cost of generating a higher pressure. The conical shaped tip is more common, though it has a larger space after the luer fitting that allows for air bubbles to get trapped.

Trade-Offs Between Nozzle Sizes

Dispense Volume: A larger nozzle size (dispense tip) allows for more fluid to move through it (larger dispense volumes) while keeping the backpressure lower. However, this setup could promote hanging drops or inaccurate shearing locations on the fluid.

Flow Rate Control: Flow rates can vary depending upon the specified application. Low flow applications are on the scale of microliters per minute, while high flow applications could be on the liters per minute scale. Although larger diameter nozzles allow more fluid to pass through and smaller nozzles restrict flow, flow rate is not typically considered a deciding factor in the selection of nozzle sizes. This is because nozzles are normally used in discrete, dispensing applications, while flow rate is generally more closely associated with metering.

Backflow Prevention: When undersized, the amount of instantaneous backpressure on the tip could alter the amount of fluid being dispensed. Combined with the viscosity of the fluid, the pressure spike could prevent fluid from dispensing from the tip.

Droplet Generation: If the inner diameter of the tip is too large, then the fluidic momentum is not sufficient to overcome the adhesion (to the dispense tip) and cohesion (to the fluid) forces. This results in hanging drops with inaccurate and inconsistent dispense volumes.

If the inner diameter of the tip is too small, then the fluid could generate a large backpressure and impact the dispense volume. Additionally, the fluid will eject from the tip at a higher velocity, increasing the chances of splashing the fluid into undesirable locations.

Nozzle Material Compatibility

In addition to finding the right shape and size, Fluid Metering engineers help you select pump component materials that are compatible with the designated mediums and application specifications. Often times, a hydrophobic plastic is used to deter hanging drops. Otherwise, a durable stainless steel nozzle is used.

Testing the Nozzle Experimentally

All Fluid Metering pumps go through thorough feasibility and verification testing. For custom solutions, the exact fluidic architecture, including the dispense nozzle, is used to ensure optimal efficacy at the customer’s installation site.

Ready to find the best nozzle for your application? By working with Fluid Metering, you'll receive one-on-one support from our dedicated engineers as well as the benefit of rapid prototyping. Contact us today to get started.

Key Takeaways: For motor control in fluidic pump systems, selecting between stepper and DC motors impacts flow precision, torque, and...

Key Takeaways: For electrical interface selection in OEM instruments, engineers should prioritize compatibility, power delivery, and noise immunity...

2 min read

Key Takeaways: In heated fluid dispensing for medical applications, warming fluids improves sterility, drug absorption, viscosity control, and...