1 min read

Analyze This: Real-Time, Repeatable Results

Key Takeaways: Fluid Metering pumps deliver real-time precision for analytical instrumentation, enabling consistent, maintenance-free performance in...

2 min read

Patrick DeRuvo

:

Updated on January 22, 2026

Designing and building a scalable, dependable, and accurate Clinical Chemistry Analyzer all begins with selecting the right components, including the liquid handling system: the pump.

As the engineer responsible for meeting your project requirements, you know you need a pump that:

Digging deeper into your design requirements, you determine your application needs a pump solution that meets one or more of the following:

The Cost of Getting it Wrong

After several rounds of collaboration with all project stakeholders and spending countless hours on the internet, you realize the impact of choosing the wrong pump can lead to building a Clinical Chemistry Analyzer that:

Moreover, delays caused by wasting time trying to find the right pump solution can lead to missing deadlines in launching your new project application.

As an engineer, you are committed to designing and building a medical device that can save people’s lives. Key to your success is finding a supply partner that shares the same values as you.

Meet Fluid Metering: Your Engineering Partner

At Fluid Metering, our product development engineering staff is committed to supporting all customer needs throughout the entire product lifecycle, from design development, testing prototypes to mass production. Our highly skilled product development and commercial teams have over 100 years of experience combined and degrees in Mechanical Engineering, Mechanical Engineering Technology, and Biomedical Engineering.

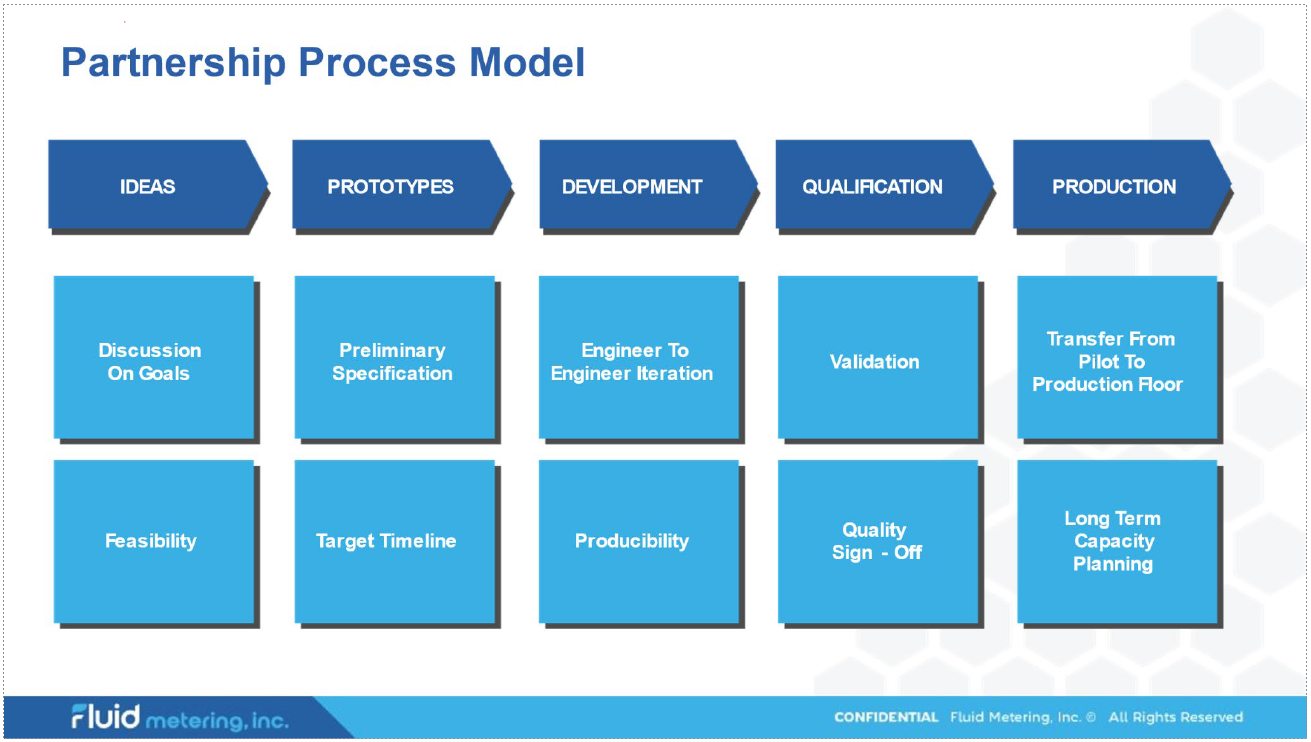

Our Proven Process

When collaborating with customers, we follow the Partnership Process model below proven to accelerate development time and reduce complexity/costs of projects.

Do you Have Questions? We Have Answers!

At Fluid Metering, we specialize in providing quality instrumentation combined with industry leading technical support and services to help meet your specific fluid management application requirements.

Our product development team is happy to help you design the right pump solution for your next project.

*Please contact our technical sales team to discuss your unique requirements and operating conditions.

1 min read

Key Takeaways: Fluid Metering pumps deliver real-time precision for analytical instrumentation, enabling consistent, maintenance-free performance in...

1 min read

Key Takeaways: For microbiology analyzer pump selection, accuracy, sterility, and chemical compatibility are essential—Fluid Metering’s FENYX® and...

1 min read

Key Takeaways: Microfluidic pumps for environmental analysismust withstand harsh conditions and corrosive fluids—Fluid Metering’s valveless ceramic...