1 min read

How Can I Meter Different Fluids at Different Flow Rates?

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...

2 min read

Thomas Breitenstein : October 9, 2025

Key Takeaways:

When Precision Matters, Every Connection Counts

In the world of precision fluid control, the smallest details can make the biggest difference. For engineers designing next-generation instruments—whether in diagnostics, environmental analysis, or industrial automation—port sizes and tubing options are more than just hardware specs. They’re foundational to system performance, reliability, and long-term success.

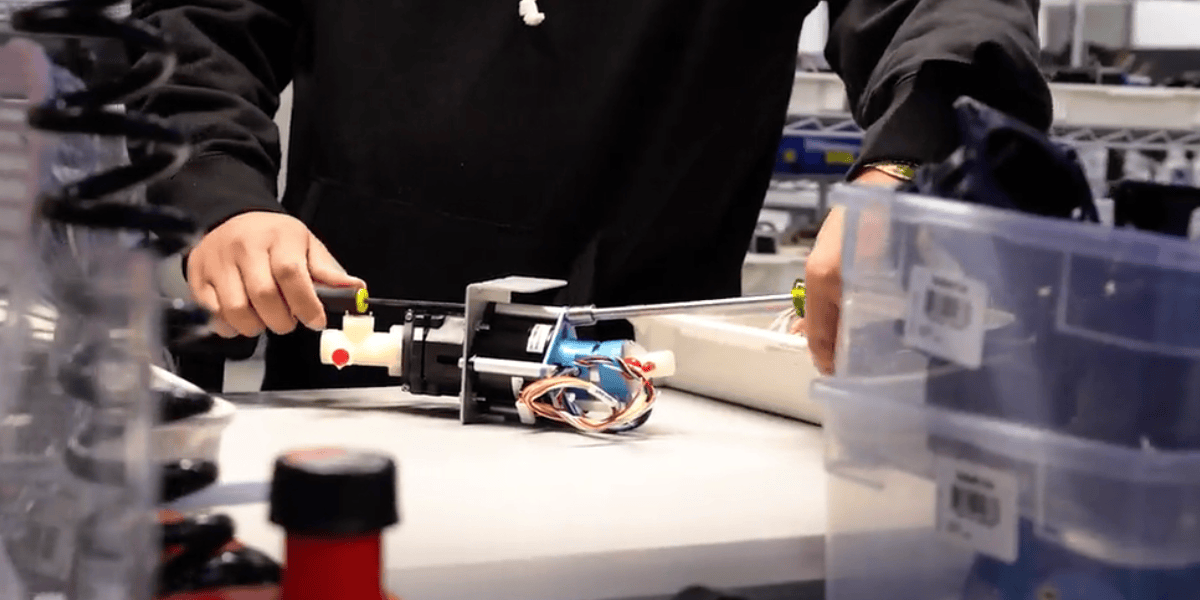

At Fluid Metering, we specialize in helping OEMs and design houses optimize every aspect of their fluidic architecture. Here’s why port and tubing choices deserve a closer look.

Precision Starts at the Connection Point

Port and tubing dimensions directly impact:

Even small mismatches can lead to leaks, variable flow profiles, or contamination from residual fluid. For applications requiring microliter accuracy, these risks are unacceptable.

System Performance: Bigger Isn’t Always Better

Understanding these trade-offs is essential for engineers who are evaluating new pump technologies for next-generation instruments.

Application-Specific Considerations

When selecting tubing and port sizes, OEMs should consider:

Tubing materials like PTFE, FEP, and Silicone offer varying levels of resistance to chemicals and temperature, while smaller diameters enhance dosing accuracy but may increase system pressure.

Handling Challenging Fluids

For crystal-forming or abrasive fluids, Fluid Metering recommends:

This is especially relevant for engineers who are troubleshooting quality issues in existing fluidic systems.

Fluid Metering’s Port and Tubing Capabilities

Fluid Metering offers a range of standard options to meet diverse application needs:

Our use of flangeless ferrule fittings and clean port geometries ensures leak-free connections and long-term durability, even in demanding environments.

Avoiding Common Mistakes

Some of the most frequent issues we see include:

Real-World Impact

In one case, a customer experienced cavitation and dosing inaccuracy due to using tubing that was too narrow for their desired flow rate. By switching to a larger diameter, they eliminated cavitation and achieved the precision they needed—proving that the right tubing choice can make all the difference.

Precision Is a System-Wide Commitment

At Fluid Metering, we know that precision fluid control is only as strong as its weakest link. That’s why we engineer every port and tubing interface with the same care and innovation as our pumps. Whether you're optimizing for accuracy, chemical resistance, or system integration, Fluid Metering has the expertise and flexibility to deliver a solution that fits—literally and functionally.

Conclusion: Customization for OEM Integration

Every application is unique. That’s why Fluid Metering offers custom port and tubing configurations to meet specific system requirements—whether you're building a compact analyzer or a high-throughput dosing platform. We specialize in collaborative prototyping, helping engineers validate performance under real-world conditions.

1 min read

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...

1 min read

Key Takeaways: Fluid Metering’s high-viscosity fluid pump solutions support thick, slow-moving liquids by using larger tubing, low RPM operation,...

1 min read

Key Takeaways: Fluid Metering’s crystallization-resistant pump solutions use valveless designs, flush ports, and hydrophobic coatings to prevent...