Fluid Metering's CeramPump® Valveless Piston Technology vs. Diaphragm Pumps

Key Takeaways: For valveless piston pumps vs. diaphragm pumps, Fluid Metering’s CeramPump® technology offers superior precision, clog resistance,...

3 min read

Dickson Ong : Updated on July 22, 2025

Different fluids with different flow rates are bound to require separate pumps, right?

Not necessarily. Two pumps aren't necessarily always better than one.

Contrary to what you might believe, just because you're working with two fluids with different flow rate requirements doesn't mean that you have to invest in two pumps. There are other options at your disposal, and these options can help streamline efficiency and conserve spending. In this post, we'll take a look at some of the options that users have when working with different fluids at different flow rates. Here's a closer look:

While there are certain situations that may warrant acquiring separate pumps for working with different fluids, users also have other options. One solution is to utilize Duplex pumps, which feature two pump heads that can be calibrated at different values.

Think of these pumps as a "2-for-1" in that, with just a single drive motor, you're able to drive two different pump heads with two different mix ratios. These types of pumps can help simplify your operations and also save you space within the lab environment.

Whether or not you need separate pumps or a single pump option can suffice is largely dependent on your application's needs, but know that there are options for purchasing two pumps to process different fluids at different flow rates. The Duplex pump is one of them.

If your application allows you to meter different fluids with just one pump, there are a variety of benefits associated with doing so. Here's a look at some of them:

In the case where the application requires flow outputs in multiples of two, having one single pump may not be advantageous. The increased complexity of the fluidic system can lead to additional leak points, increased system size, increased cost, and overall added complexity to the fluid system.

Like we said earlier in this piece, the decision to work with one pump versus two separate pumps should be based on the application you're working with. This is an example of when it would make sense to work with two pumps.

Fluid Metering, Inc. has a variety of "Duplex" pump options that can help users experience the benefits of using a single pump for processing different fluids at different flow rates. From stepper base options to our QB series of pumps, we have various models with dual shaft or dual head options.

If you'd like more information or are searching for a specific type of pump, we encourage you to give one of our experts a call so that we can help meet your application's needs. It's always best to contact us so we can ensure the solution meets your needs. Doing so can help determine the best combination of pump head to calibration for the specific application.

While the Duplex pump was largely discussed in this post, many other products in Fluid Metering's product portfolio can be utilized for the same purpose.

Key Takeaways: For valveless piston pumps vs. diaphragm pumps, Fluid Metering’s CeramPump® technology offers superior precision, clog resistance,...

1 min read

Key Takeaways: For precision fluid metering vs. centrifugal pumps, Fluid Metering’s valveless piston pumps offer unmatched accuracy, chemical...

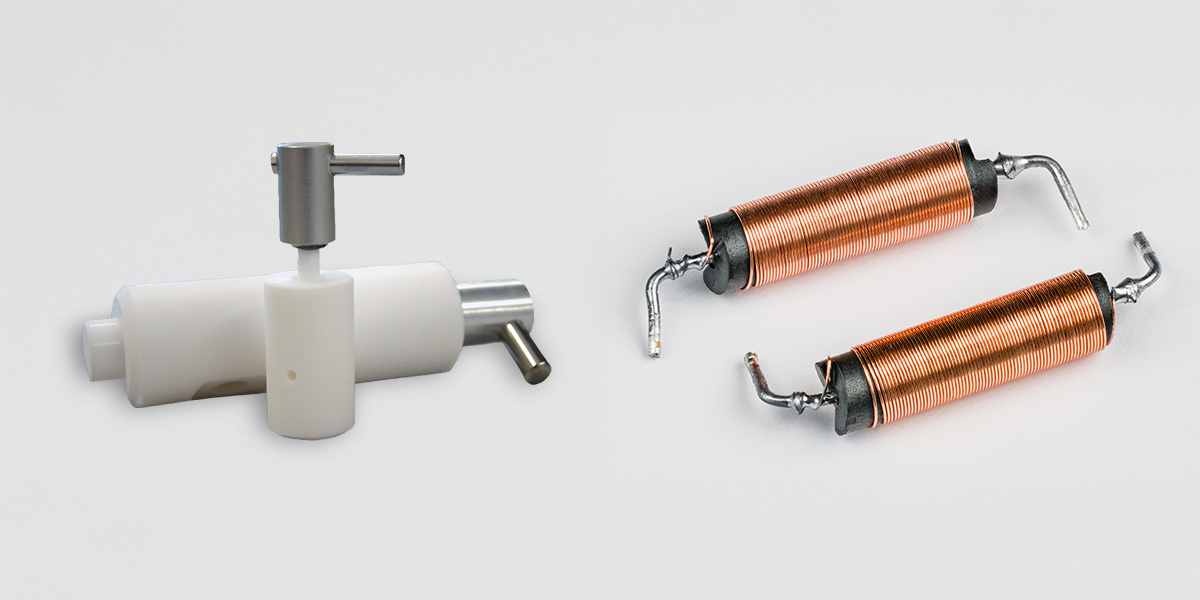

Key Takeaways: For precision fluid delivery vs. solenoid pumps, Fluid Metering’s valveless piston pumps outperform in accuracy, reliability, and...