2 min read

Precise Dispensing of a Heated Fluid

Key Takeaways: In heated fluid dispensing for medical applications, warming fluids improves sterility, drug absorption, viscosity control, and...

When referring to flow rate in a pump, you are looking to find the volume of liquid that travels through the pump in a certain amount of time, often measured in milliliters per minute. Different applications will require different flow rates — and it's crucial to select a pump that can meet your specific needs. In this post, we'll take a closer look at how to select the right pump for flow rate, what to look for, mistakes to avoid, and more.

Why is it so important to select a pump based on flow rate? On a very basic level, doing so is essential to ensuring that the pump is working well and meeting user expectations. Other pump components such as ports, tubing, and overall fluidic setup are crucial to establishing an accurate flow rate.

For example, if you choose a pump where the ports are too small, then not enough fluid is going to be distributed to the pump head. This won't just result in a poor flow rate, but it can also cause other issues such as cavitation.

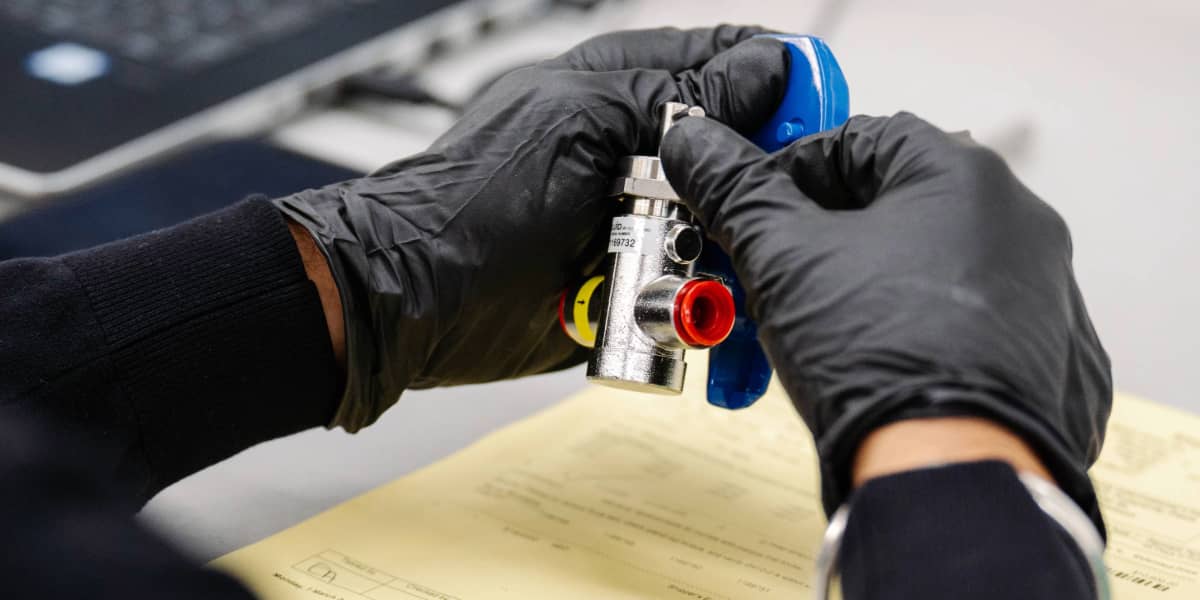

So how do you select the right pump? It all starts with having a good idea of the flow that you want and then selecting a suitable pump head. And as we previously noted, the right components are essential. Contrary to what many people believe, you can't just purchase a pump and then modify it so that it works with the flow rate you expect. Have a firm grasp on information such as fluid type, viscosity, and more so that you're better able to determine the pump that will best suit your application. The more information you have, the better pump selection you're able to make in the end.

There are three main factors to consider when you're selecting a pump for your application:

These three variables are crucial to ensure you're getting the correct expected flow rate that you need for your fluid application. Another important desired factor relative to the flow rate that is desired is piston size.

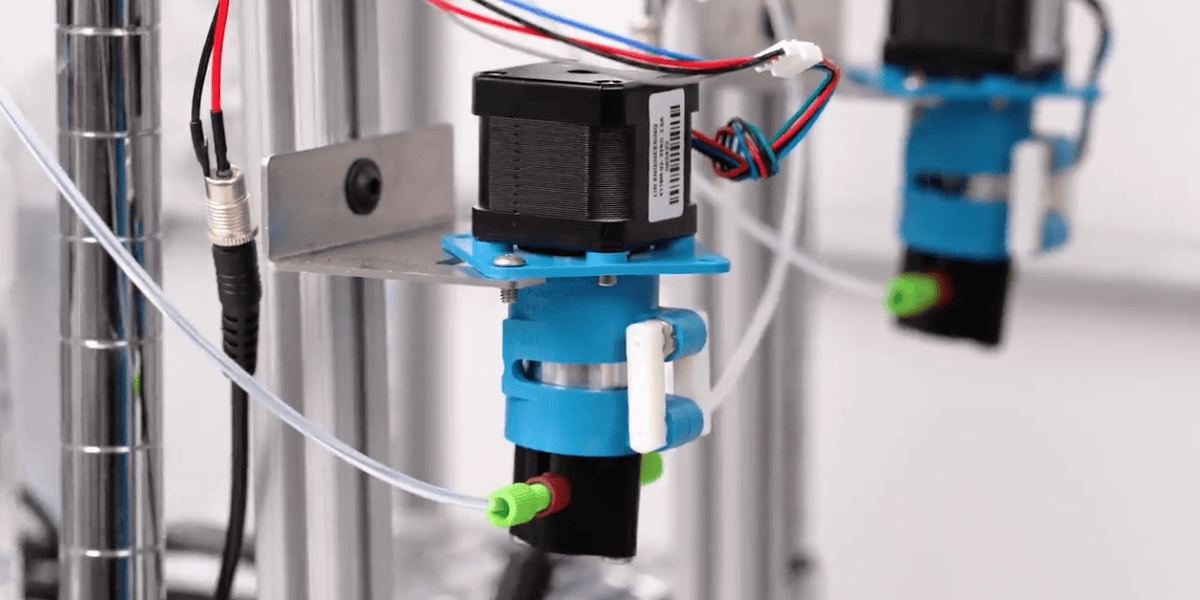

For instance, Fluid Metering offers a Q Series and an H Series of pumps, the former which are designed for higher flow rates and the latter for lower flow rates. The H Series of pumps is ideal for flow rates of anything less than 100 millimeters per minute, while the Q Series is ideal for anything more than 100 millimeters per minute.

If there is any question about what type of pump to select based on your application, it's always worth consulting with the experts. Our team of experts at Fluid Metering have more than 60 years of experience with just about every kind of application and can work to provide a solution to meet customer requirements and exceed expectations.

It's especially helpful to consult with Fluid Metering experts for any new applications that you haven't worked with before to better ensure that your pump will meet its expectations. Oftentimes, users make mistakes that involve a lack of chemical compatibility between the application and the pump that is being used. This can lead to problems during pumping.

Another common mistake is over or underestimating tubing size. If the tubing is too small, cavitation will occur. If it's too large, the fluid will take a really long time to prime the pump. In addition, choosing the incorrect drive motor for the application is another oversight we see. It's important to choose the right drive motor for your specific needs from the variety of options we have in our portfolio of pump drive modules.

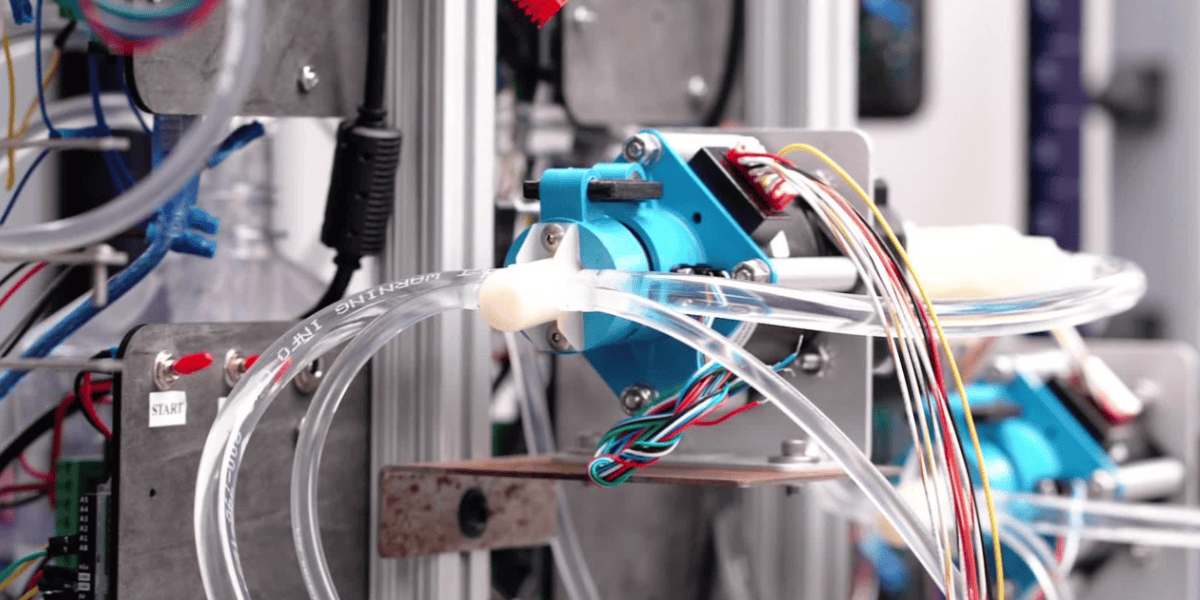

Pumps are modular in how they're put together — and it's the drive and the pump head that help determine the flow rate for the complete pump. The drive determines the range for the flow rate. A variable speed motor provides a wider flow rate range than a fixed speed motor. This is largely because variable speed motor RPM can be adjusted electronically. However, a variable speed motor is often more expensive since a controller is required, while a fixed speed motor is more affordable.

Again, it's worth noting that pumps are modular and can be customized if a base model does not meet user requirements. It's why it's important to involve the experts if there's any doubt about what type of pump is right for your application. By working and collaborating with Fluid Metering pump experts, you're able to customize just about anything and also help avoid any compatibility problems that could arise. From tubing to motors to the right materials, it's always worth it to put in the work upfront to ensure a successful end product.

Contact us today, we would be happy to assist you with high quality fluid control solutions.

2 min read

Key Takeaways: In heated fluid dispensing for medical applications, warming fluids improves sterility, drug absorption, viscosity control, and...

1 min read

Key Takeaways: Fluid Metering’s high-speed, high-pressure pump solutions—including the QD, QBLDC, and STF series—are designed to handle...

1 min read

Key Takeaways: Fluid Metering’s chemically compatible pump materials—including ceramic, PTFE, and corrosion-resistant alloys—are critical for...