1 min read

The Advantages of Fluid Metering Piston Pumps Over Peristaltic Pumps

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

Depending on your application, you may require a pump that can work at high speeds and manage high pressure - and not all pumps function this way. If you require a pump that can manage high speeds and high pressure and select a pump that does not function at that level, you could be facing costly unplanned downtime, lost productivity, and even premature pump failure. Fluid Metering experts can help with selecting a pump that meets your speed and pressure needs.

When it comes to pumps, it is important to choose a pump that administers your required speed and flow rate. High speeds are also important when dispensing volumes on the microliter scale. It is common for fluid to adhere to dispense tips when dispensing over air. A pump that can manage high speeds helps to shear the fluid off the tip to release smaller volumes of fluid over air.

However, higher speeds can often cause a buildup of pressure in a system. When both factors are high, it is important that you have a pump motor that can manage each in an adequate manner.

Pump speed and pressure are performance characteristics considered in about any industry – including biomedical, diagnostic, industrial, and agriculture. Any fluid that you are trying to pump at high speeds is going to encounter issues if you do not have the right type of pump.

If your current pump cannot handle high speeds and pressure, the motor, and thereby the pump, will stall out. If the pump stalls out, it will not be able to dispense any more fluid, which could result in unplanned downtime, lost productivity, and excessive maintenance costs.

Occasionally, too much pressure may also result in the fluid pumping backward within the pump and creating backflow. Too much pressure may also cause incorrect dispensing volumes. This is especially true with viscous fluids.

Finding that speed and pressure sweet spot is important in any industry with any fluid that you are pumping. Here are key considerations for finding the right pump for your application:

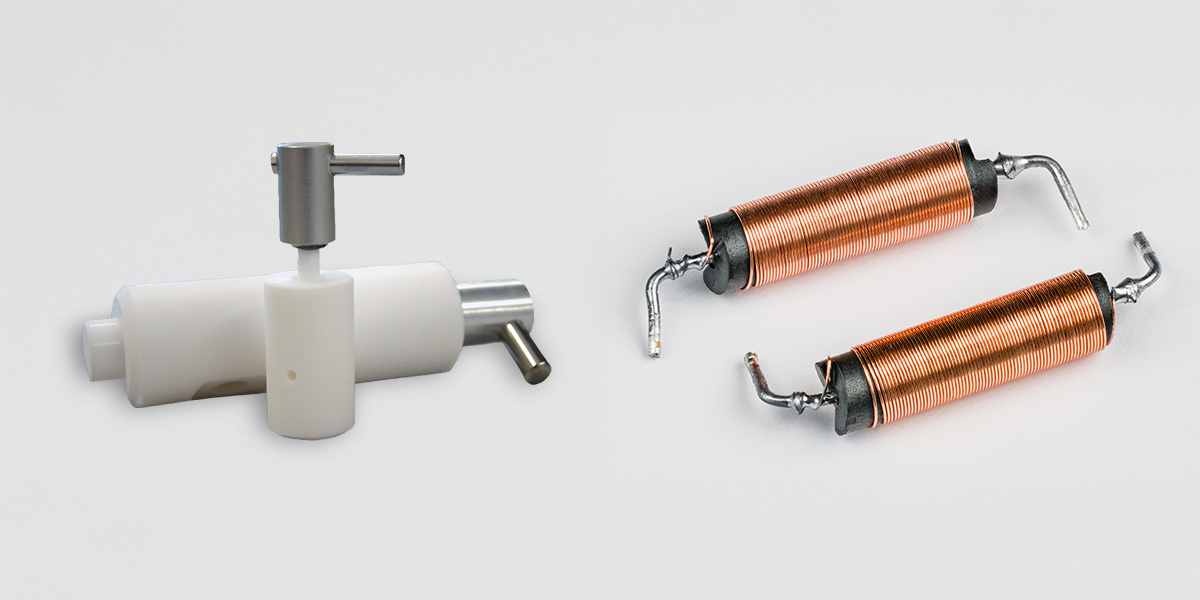

Aside from what we have outlined above, there are other considerations when it comes to selecting the right pump for your application. One is chemical compatibility. If you are considering a high-speed pump head, be aware of construction material. For example, there are various fluids that are not chemically compatible with stainless steel.

Dispensing requirements are another consideration that users should be weighing. As cited earlier, there are users who only need to pump a small amount of fluid and need a high-speed pump to ensure the fluid will disperse appropriately and will not stick to the dispense tip.

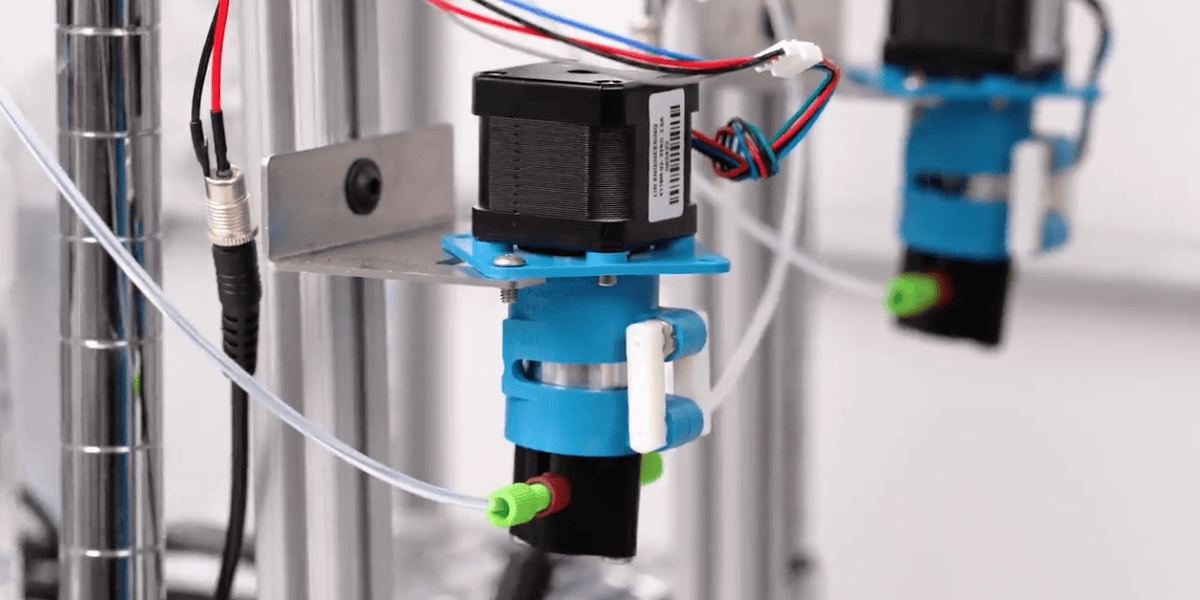

Finally, how you are driving the pump is a key consideration. There are diverse types of motors that can drive a pump, such as stepper and DC motors. If one of these is not going to work with your application, then you will need a completely different type of pump assembly. It is critical to understand this before moving forward with a purchase.

To further understand pump speed and pump pressure and to learn more about the type of pump that would be best for your application, contact us today.

1 min read

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

Key Takeaways: For precision fluid delivery vs. solenoid pumps, Fluid Metering’s valveless piston pumps outperform in accuracy, reliability, and...

Key Takeaways: Fluid Metering’s viscosity-tolerant precision pumps maintain accuracy across a wide range of fluid viscosities by optimizing tubing...