Are your Medical Device Pumps Ready for a PFAS Conscious Market?

Key Takeaways: PFAS scrutiny is reshaping pump selection — OEMs must prioritize material compatibility, regulatory defensibility, and long-term...

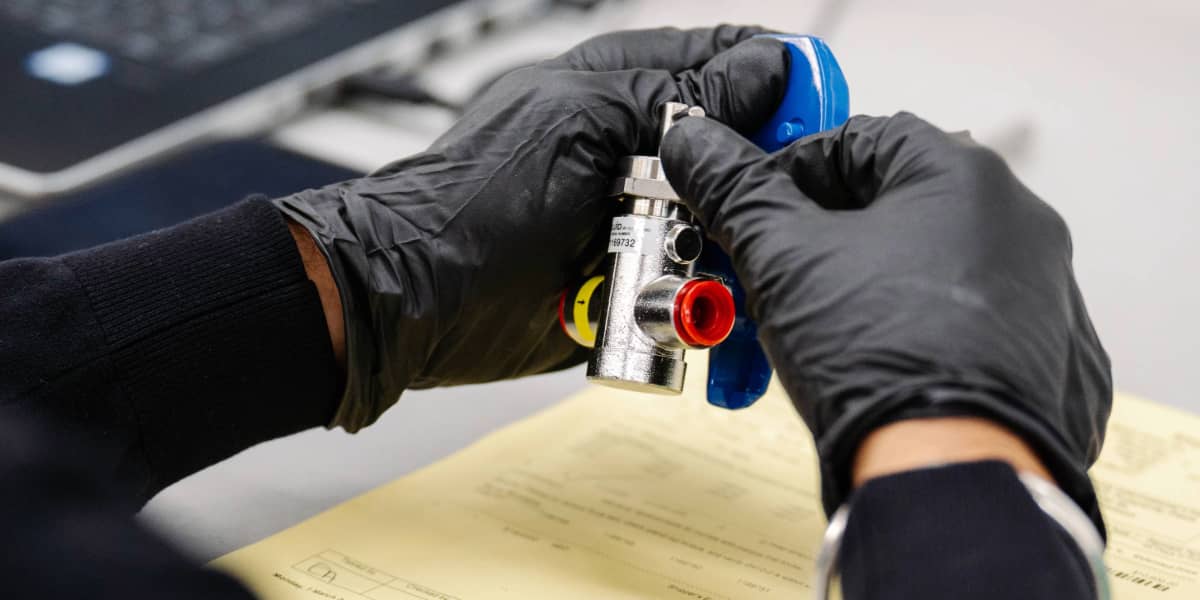

Frequent jams, busted pistons, blown seals, and material degradation are all things to be avoided with any pump you purchase. But if you fail to ensure your pump is crafted from the right materials based on the chemicals and fluids it's intended to work with, that's exactly what might happen, halting productivity and incurring additional expenses. In this post, we'll take a closer look at just why pump materials are so important.

The last thing you want is a pump that either breaks or melts shortly after you acquire it. But if you fail to select the correct material makeup, the chances of this happening will rise.

For example, if the fluid you're processing is crystal-forming when it's exposed to air, your chances of jamming the pump and damaging the piston increase. When this occurs, you'll likely have to replace pump parts or even the entire head.

Another example is fluid that hardens when exposed to UV rays. If you're working with such fluids, you'll need to ensure that your pump is crafted from materials that won't allow UV rays to penetrate it. Should this occur, the fluid will likely harden inside of the pump, damaging it to the point where it's no longer usable.

Let's look at some dos and don'ts when it comes to material selection for your next pump:

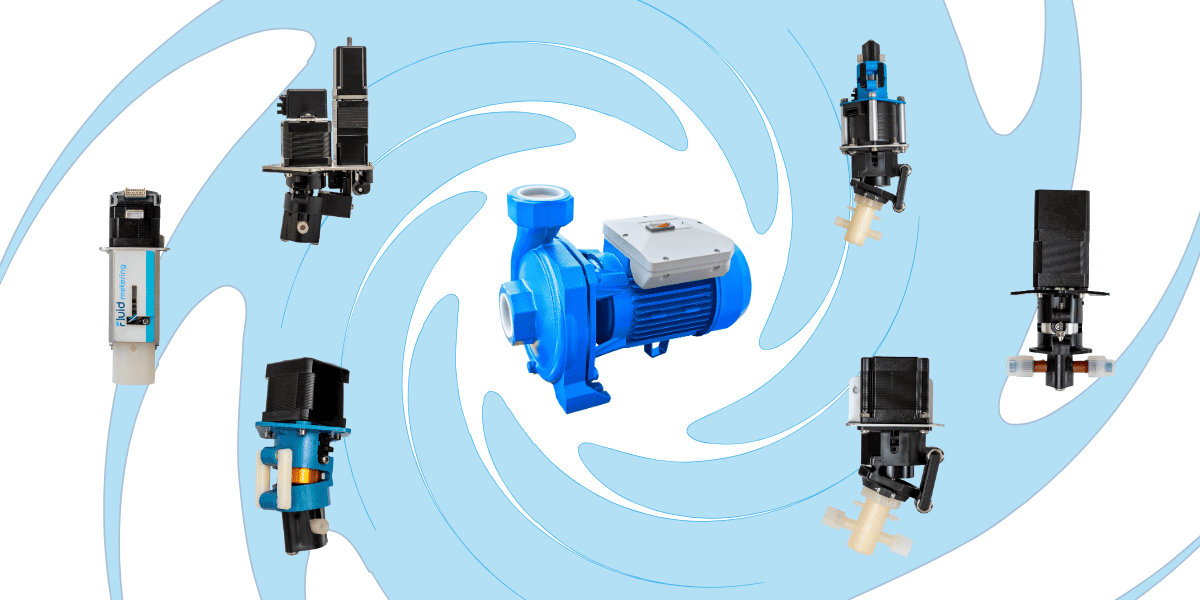

Remember, pumps aren't so much industry-specific as they are chemical/fluid-specific.

We already discussed the importance of the MSDS document, but it's also important to analyze tables of material compatibility to ensure that the pump materials you're considering will stand up well to your intended use. But keep in mind that just because a chemical may be compatible doesn't necessarily mean that its reactions will not cause some difficulties during use — so it's important to understand this too.

An example of this is nitric acid. Nitric acid is compatible with PVDF, or polyvinylidene difluoride. However, depending on the concentration of the nitric acid, the fluorocarbon may expand or balloon when the requirement is that the material stays constant. This expansion can have an impact on accuracy and also affect overall pump performance.

Aside from the chemical or fluid that is being processed, there are other considerations that should be weighed when selecting pump materials. Here's a look:

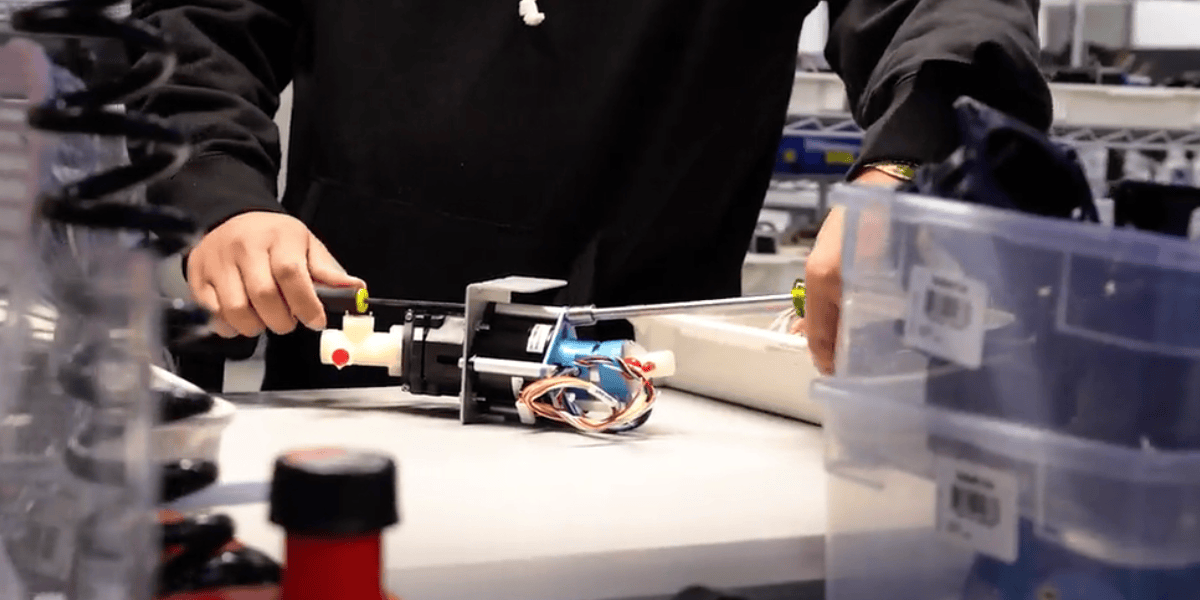

As we mentioned as one of the "dos" earlier in this piece, we always suggest consulting with an expert that can help you better understand the type of pump makeup that would work best in your specific situation. At Fluid Metering, our experts work closely with our product development and engineering teams to conduct thorough life tests on any pumps under consideration to ensure that they'll meet the pump needs you require. Fluid Metering’s knowledgeable team is happy to provide detailed reports and insight to ensure that you have confidence in your pump selection.

%20(9).png)

Key Takeaways: PFAS scrutiny is reshaping pump selection — OEMs must prioritize material compatibility, regulatory defensibility, and long-term...

1 min read

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...

1 min read

Key Takeaways: For precision fluid metering vs. centrifugal pumps, Fluid Metering’s valveless piston pumps offer unmatched accuracy, chemical...