1 min read

Mosquito Abatement: Understanding The Right Approach to the Application’s Success

Key Takeaways: In ULV mosquito fogger pump systems, durability, repeatability, and chemical compatibility are critical—Fluid Metering’s ceramic...

3 min read

Luis Cajas

:

Updated on July 22, 2025

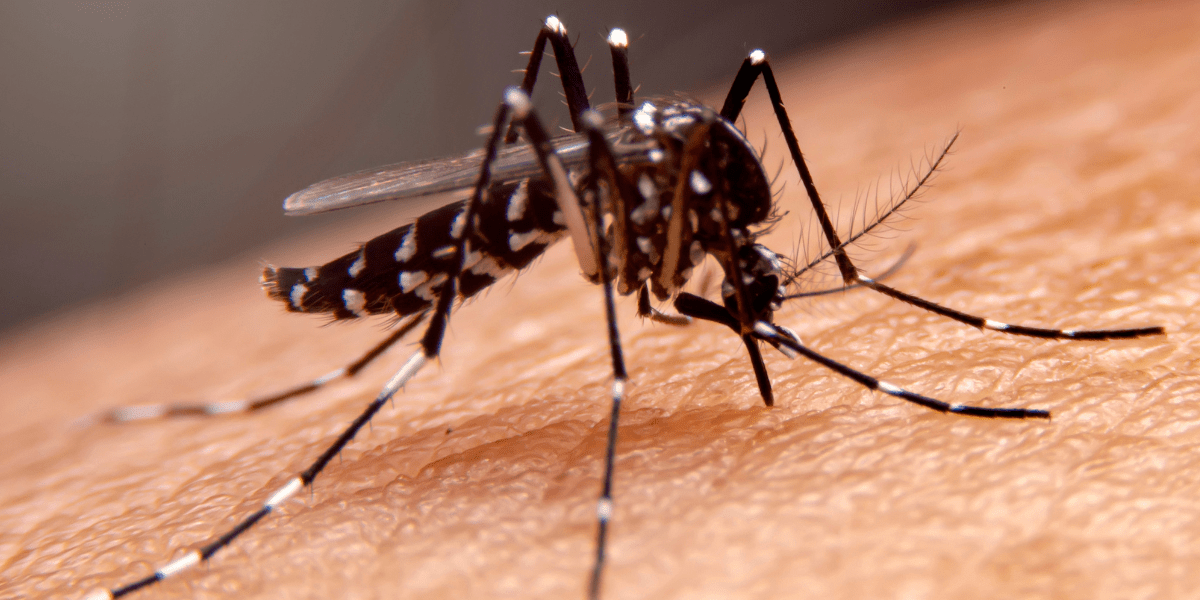

When considering changing laws, it will be important for mosquito abatement manufacturers to understand new chemical and fluid regulations as innovations begin.

In the latest installment of Fluid Metering’s spotlight series, Luis Cajas, Customer Care Manager at Fluid Metering, interviewed Chris Norgren, President and CEO of London Fog, to learn more about the types of fluids pumped in mosquito abatement applications and the potential for next-generation applications.

In the first part of the conversation, Chris discussed the ease of changing the fluid pump in the fogger for their primary clients: doctors of epidemiology and farmers. He also talked about the common mistakes that other manufacturers make when selecting a pump partner.

The following interview has been edited and condensed for clarity.

Luis: What is the average lifecycle of a fogger and the pump installed in it?

Chris: Well, the average lifecycle of our biggest fogger is ten years. From the perspective of the pump, the average lifespan averages about half the life of the machine, since customers might put 7,000 to 8,000 total hours on a pump during the machine’s ten years.

Luis: Throughout the pump's lifespan, are you moving a concentrated pesticide or is it premixed?

Chris: Both. In the United States, the EPA has a registration process that regulates approved pesticides and what can be pumped through a fogger for vector control. Most of the fluids are water or oil-based, not very viscous, and easy to deal with. The two main pesticides that are available in the United States are malathion and permethrin. Typically, they are diluted for spray cycles because it’s cost-effective. For permethrin, a 2.5-gallon container probably costs $200.00 in the market today. If a customer is spraying 6 ounces (about 177.44 ml) per minute, that adds up quickly. The chemical costs of a spraying system cycle for mosquito control are much more expensive than the fogger or the pump ever will be.

Luis: What are the typical characteristics of the chemicals being pumped? Is it sticky? Viscous?

Chris: They’re sticky and viscous but not like syrup. There are certifications from different associations and the EPA. In all cases, a person would have to wear gloves and face protection when handling these difficult chemicals. PPE is documented on a MSD sheet for protective equipment. For example, outside of the United States, thermal foggers are more common, and a person might wear full-body hazmat suits because it’s difficult to use and difficult to manage the chemicals since it can produce harmful fumes.

Luis: Are there any regulations or software applications that can help your customers know which days they’re able to operate or connect to satellites?

Chris: For some mosquito districts in the United States, when they are out trying to kill mosquitoes and pests, they end up killing the good insects too. Some trucks are equipped with mapping and tracking software used to identify no-spray zones.

There is also a flow and speed control antenna that regulates the speed and flow rate of the fogger. If someone is driving at three or twenty miles per hour, it sprays out a specific rate for that speed. When that person stops at a stop sign, the fogger shuts off. Geo-mapping software is becoming popular for mosquito districts because it can follow the machines and spray at certain areas or shut down when going through a no-spray zone. It’s not a perfect science but it works through the GPS mechanism bouncing off satellites.

Luis: Are there any new innovations coming to mosquito abatement? What do next-generation applications look like?

Chris: There is an influx into the drone industry. Right now, it’s a very elemental stage for the pump perspective. Drones are less costly from a labor standpoint, and they can fly into a small area that need to be fogged. It’s an adjunct to helicopters and airplanes.

We’re also seeing a shift in state laws that can impact how mosquito abatement trucks operate. By the end of 2024, we currently won’t be able to sell in California because of the carbureted engine attached to the fogger. Right now, we’re experimenting with different battery-powered units.

Luis: Thank you for your time today, Chris. We look forward to continuing our partnership and helping you innovate for next-generation applications.

1 min read

Key Takeaways: In ULV mosquito fogger pump systems, durability, repeatability, and chemical compatibility are critical—Fluid Metering’s ceramic...

1 min read

Key Takeaways: Fluid Metering’s precision pumps for silica bead slurries handle particle sizes from 3µm to 800µm with low shear, no entrapment, and...

1 min read

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for OEM applications offers programmable dispense volumes (2–400 µL), self-priming,...