What is Pulsation?

Key Takeaways: In microfluidic pump systems, pulsation refers to periodic flow rate fluctuations that can impact accuracy, stability, and...

3 min read

Luis Cajas

:

Updated on November 3, 2025

During a recent trip to Fluid Metering’s exclusive distributor in Australia, Luis Cajas, Customer Care Manager at Fluid Metering, sat down with Andre Wyzenbeek, Director of Sales at John Morris Group, to highlight the newest technologies for engineers who are building OEM applications in the medical or life sciences industries. With 26 years of microfluidic experience, Luis understands the complexities that engineers encounter when creating next-generation fluidic applications that require a rigorous list of requirements.

In his conversation with Andre, Luis discusses the STF, fixed dispense pump, and FENYX® Variable Dispense Pump (formerly FVD). Fluid Metering’s FENYX Variable Dispense pump can perform priming, flushing, and dispensing in one pump. This allows engineers the ability to adjust the dispense volume between 2 to 400 µl through the linear actuator dynamically and automatically.

This interview has been edited and condensed for length and clarity.

Andre: Can you tell me more about Fluid Metering and what makes your company so special?

Luis: We are a company that focuses on mission critical fluid transfer control that can deliver between one microliter to two liters per minute. Our pumps are currently used in many specialized instruments around the world.

Andre: Can you explain the core technology that makes Fluid Metering pumps run for so long?

Luis: Most of our pumps are designed with ceramic pistons and liners, CeramPump®, that are chemically inert and provide a clearance of one-tenth of a millionth of an inch. The construction and materials of this core technology provides the necessary requirements for accuracy and precision.

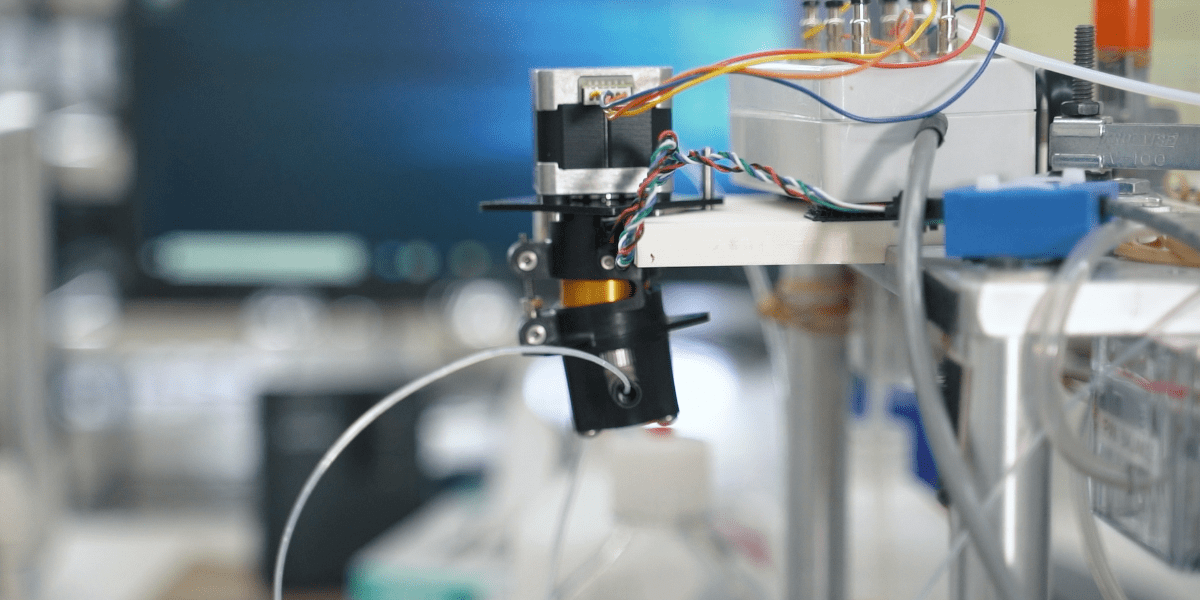

Andre: When I look at Fluid Metering’s dispense pump options, there are wires coming off the top. How would an engineer be able to control these pumps?

Luis: These options are equipped with a stepper motor. A prospective customer would need a stepper motor controller to interface with the unit. In most use cases, our current customers have their own stepper motor controller because they have different programs that they want to integrate or goals they want to accomplish. But we do have controllers available in-house for these dispense pumps. As long as the customer can control the stepper motor, they’ll be set.

Andre: So, the stepper motor enables you to have precise control of the rotations which enables you to have control over your speed of delivery?

Luis: Yes.

Andre: Since the fluid path and wear parts are dimensionally stable and chemically inert, that means you have an enormously long lifetime for the product.

Luis: Absolutely.

Andre: When looking at the STF, valveless piston pump, how do you change the volume which is dispensed over a minute?

Luis: If you look at the eccentric bushing, you can see that there is an angle to the pump, this can be manually adjusted to fit your application needs. The angle of the pump and the size of the piston determines how much fluid will be delivered precisely.

Andre: If an engineer wanted to change the volume delivered over time automatically, what would be the solution?

Luis: Our automated solution would be the FVD (now known as FENYX), variable dispense pump, since it provides superior support and flexibility when adjusting the angle of the pump. FENYX is built with a linear actuator that can open and close the angle automatically with an electronic signal. This allows for continuous precision and eliminates the need to manually readjust the angle.

Andre: It sounds like FENYX variable dispense pump, gives you an incredible amount of accuracy and precision. If the liquid has granules or particles, is that going to be a problem for this pump?

Luis: If the particles are less than 700 microns and it depends on the percentage/concentration of how many particles are in the fluid, the pump will handle them. The other thing that you want to keep in mind is that you want the particles to remain suspended in the solution and for them to be softer than the ceramic.

Andre: What would normally happen is you would hope the customer would provide their preferred flow rate, chemical materials, and how they want to control the actual pump. You put all of those things together to mix and match components to get the optimum solution for them.

Luis: Absolutely.

Andre: Can you deliver your pumps quickly?

Luis: Yes. For most of our pumps, the lead time is about 10 business days (dependent on component availability, location, and shipping requirements).

Andre: If you need a pump solution that can dispense anywhere from one microliter up to two liters per minute, accurately, reliably, and outlast the instrument or installation that it’s put in, don’t be shy to reach out to Fluid Metering’s distributors or the company directly.

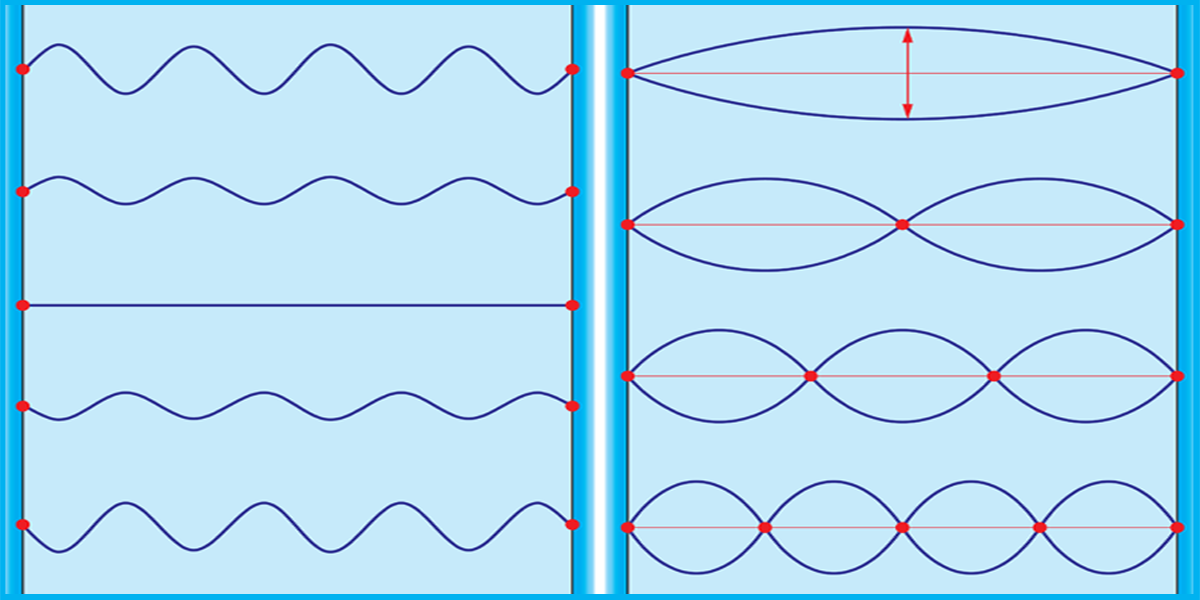

Key Takeaways: In microfluidic pump systems, pulsation refers to periodic flow rate fluctuations that can impact accuracy, stability, and...

1 min read

Key Takeaways: Fluid Metering’s precision pumps for silica bead slurries handle particle sizes from 3µm to 800µm with low shear, no entrapment, and...

1 min read

Key Takeaways: Fluid Metering’s FENYX® pump for non-contact dispensing enables accurate, sterile fluid delivery under 10 µL without tip submersion...