1 min read

The Advantages of Fluid Metering Piston Pumps Over Peristaltic Pumps

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

4 min read

Blake Webb & Patrick DeRuvo : Updated on July 22, 2025

Pumping fluid with suspended particles like silica beads requires a tailored approach. The key to successful dispensing lies within the ability to understand and take into account the unique properties of these particulate-laden fluids. Let’s explore how Fluid Metering’s precision pump technology can overcome these distinctive challenges to provide optimal solutions for pumping silica bead slurries.

Type of Bead Mixtures for Use in Fluid Metering Pumps

Not all silica beads are pure silica. Knowing the differences between their properties and applications can help serve in the pump selection process.

Understanding the Challenges

Since silica beads vary and have so many unique characteristics, one must understand each variable in order to find the best pumping solution for micro silica bead slurries. Such factors include:

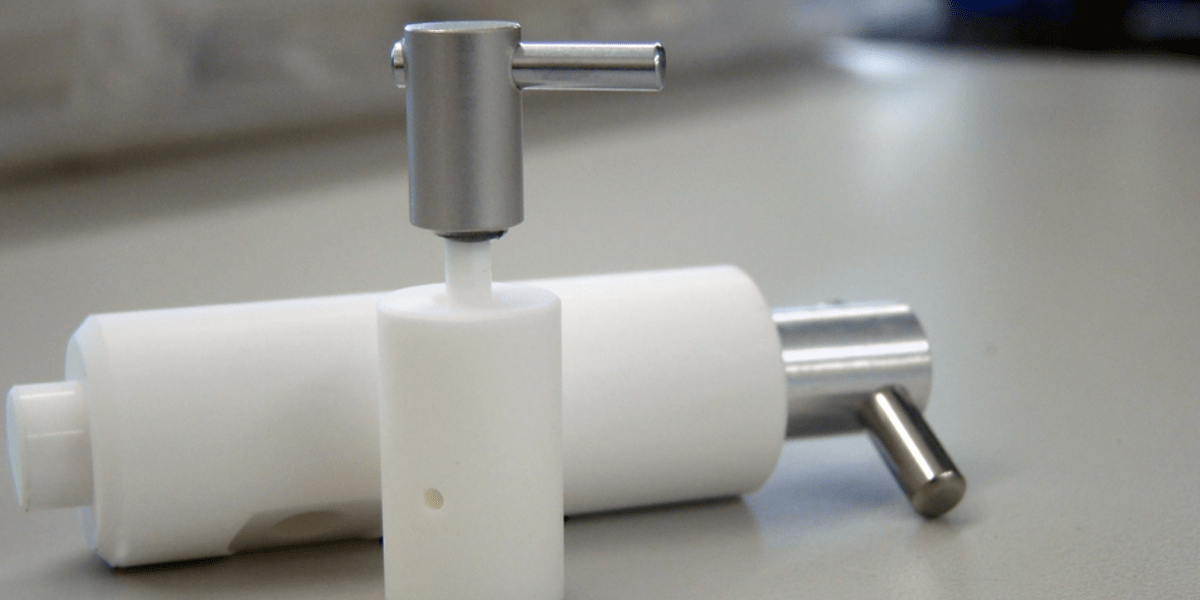

Low Shear: Ensuring integrity of beads is of high importance. Fluid metering’s Cerampump® offers low shear due to its gentle rotating, reciprocating motion. This ensures beads are not damaged when being dispensed through the pump.

No Bead Entrapment: With Fluid Metering’s valveless piston design and ultra smooth surfaces, there are no additional valves to catch or entrap beads in the fluidic path. This leads to long-term, highly repeatable dispenses with low maintenance. In addition, the wetted path contains no magnetic properties making it ideal for pumping magnetic beads.

Pressure Requirements: In order to prevent damage to the pump system and protect the integrity of the silica beads themselves, Fluid Metering engineers can help optimize pump design, targeting low pressure, low speed flow coupled with low dispense volumes. The use of our advanced ceramic materials, including our CeramPump® technology, offers superior wear resistance against your media’s potentially abrasive edges.

Particle Settling & Suspension: When designing a pump for bead mixture dispensing, it’s important to let our engineers know if your bead mixture has settling or suspending qualities. Due to density and flow factors, some particles tend to naturally settle while others remain suspended within the liquid. Fluid Metering’s CeramPump® design is optimized for suspended bead dispensing and, depending on certain variables, can often handle settling mixtures. If working with a settling mixture, we recommend pre-mixing the formula prior to pumping.

Particle Size, Concentration, & Viscosity: The higher the concentration and viscosity of the silica bead slurry, the higher the risk of abrasion, clogging, and seizure. To mitigate these risks, Fluid Metering's engineering team recommends discussing options that best suit your application including flushing ports and different geometries. This will ensure particles can pass through the pump to maintain the necessary flow.

Fluid Metering pumps have been known to pump particle sizes from 3µm to 800µm. Often, it is very important to take a collaborative approach with OEM partners to be certain our pump is optimized for your particular sample. Fluid Metering offers in-house testing capabilities to address these concerns.

For fixed dispense volumes ranging from 1µL to 400µL, please see our STF Fixed Dispense Pump 🡺

For fixed dispense volumes ranging from 400µL to 1280µL, please see our STFQ Fixed Dispense Pump 🡺

If your recipe has different dispensing callouts ranging from 2µL to 400µL, please see our FENYX™ Variable Dispense Pump 🡺

For ultra gentle delivery up to 150µL, please see our TRYTON™ Pulseless Nanoliter Pump 🡺 (secondary valving is required).

Maintenance Protocols: Flushing the system after use ensures long-term reliability and performance, especially when dealing with particulate-laden fluids. For self-flushing capability, Fluid Metering offers the FENYX™ Variable Dispense pump, a unique 3-in-1 design that primes, dispenses, and flushes.

What Are Silica Bead Slurries Used For?

Micro silica beads, also known as silica microspheres, have a variety of applications across different industries due to their ability to remain chemically inert under most conditions and their exceptional physical properties. Here are some common uses for micro silica bead slurries:

Chromatography: Silica beads are often used as a stationary phase in column chromatography for the separation of compounds based on their size, charge, or affinity.

Diagnostics & IVD: In the medical field, silica beads are used in diagnostic assays and tests, including those that require DNA and RNA extraction. Silica beads are also used as a reagent indicator in blood test kits. When blood gets tested before going into a blood bank, silica beads capture blood cells on their outside surfaces as the cells travel down the test card.

Biotechnology: They are utilized in bioprocessing applications, such as cell lysis, protein purification, and as carriers for enzymes and other active biomolecules.

Drug Delivery: Silica beads can be used as excipients for controlled drug delivery systems due to their mesoporous (2nm - 50nm pore diameter) to nanoporous structure, which allows them to encapsulate, carry, and protect therapeutic agents as they travel through veins.

Environmental & Analytical: In environmental testing, silica beads can be used for sample preparation, pollutant removal, and as a medium for detecting various environmental contaminants.

Cosmetics & Skin Care: In the cosmetics industry, silica beads are used as additives in products like exfoliating scrubs, deodorant, sunscreen, and makeup. They’re able to hold their shape better than other materials like plastic, making them smoother against skin, and are made from naturally occurring minerals, making them environmentally friendly.

Catalysis: Silica beads can serve as supports for catalysts in chemical reactions, providing a large surface area for catalytic activity. In other uses, they’re also able to immobilize certain catalysts.

Adsorption: They are effective adsorbents for moisture, odors, and chemicals, making them useful in packaging and storage solutions. (You’ve probably seen the larger-scale silica bead packs in shoe boxes.)

Research & Development: Silica beads are used in laboratories for various research applications including studies of particle behavior.

Partnering for Success

Pumping micro silica bead slurries demands a pump technology that’s robust, accurate, and adaptable. Fluid Metering's precision metering pumps, particularly our TRYTON Pulseless Nanoliter series, rises to the occasion, offering unparalleled performance in the face of challenging fluidic applications. By partnering with Fluid Metering, you can ensure that your fluid handling processes are efficient, reliable, and fitted to your specific requirements. Contact us today to learn more about how we can assist with your silica bead pumping needs and drive your application forward.

1 min read

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

Key Takeaways / Highlights Piston pumps(rotating and reciprocating) offer unmatched precision, chemical resistance, and longevity—ideal for...