A Guide to Low-Maintenance Microfluidic Pumps

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

2 min read

James Cotrone & Elijah Qasim : Updated on July 22, 2025

Microfluidic pumps used seasonally must be maintained in a systematic manner to ensure their functionality, longevity, and reliability when they are next needed. Here's a comprehensive guide to off-season maintenance:

Before Storage (End of Season)

Thorough Cleaning:

Inspect and Repair:

Drain the System:

Lubrication:

Winterization:

Storage Conditions:

Cover and Protect:

Avoid Direct Sunlight:

Ventilation:

Before Use (Start of Season)

Visual Inspection:

Test Seals and Connections:

Flush the System:

Prime the Pump:

Test Run:

Recalibrate:

Routine Maintenance During Use:

Upgrades and Recommendations:

Conclusion

You can ensure your microfluidic pumps remain operational and effective across multiple seasonal cycles by combining proper off-season storage, pre-season preparation, and regular use maintenance. Following these steps will help keep your pumps running efficiently and reliably, lower repair costs, and extend service life. Contact us today for more seasonal solutions.

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

1 min read

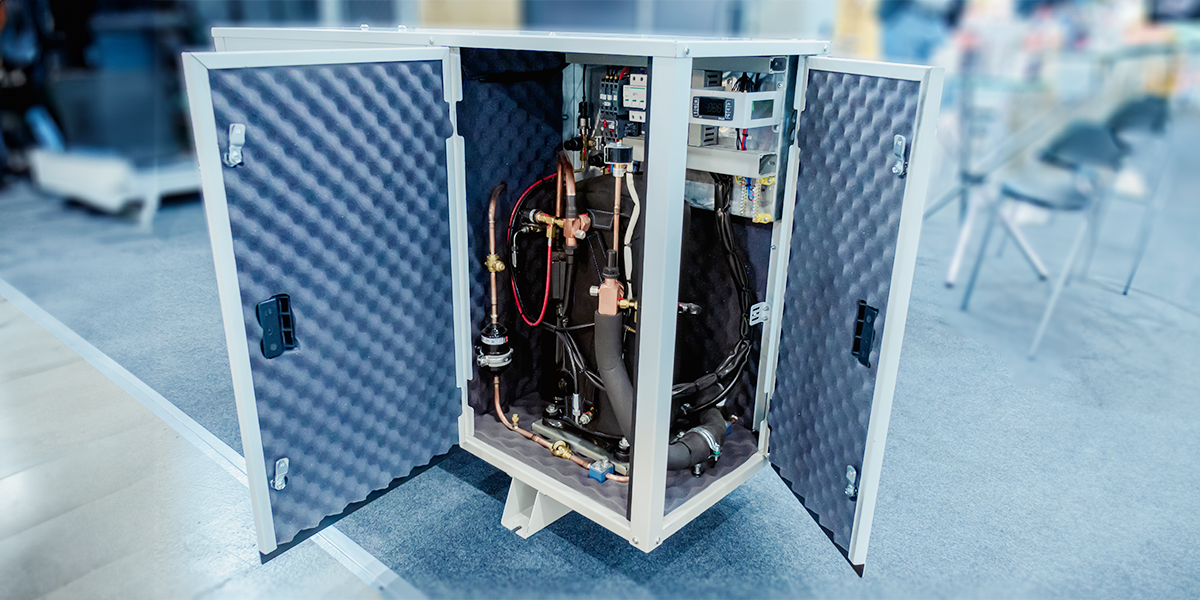

Key Takeaways: In low-noise microfluidic pump applications, such as home dialysis or dental devices, reducing vibration and acoustic output is...

1 min read

Key Takeaways: Biological samples can contaminate pump internals, reducing accuracy, causing biofouling, and requiring costly, time-consuming...