1 min read

The Advantages of Fluid Metering Piston Pumps Over Peristaltic Pumps

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

2 min read

Stephanie Moreau : Updated on July 22, 2025

Microfluidics, the science of manipulating fluids at the microscale, has revolutionized various fields, from medicine to chemistry and beyond. In this intricate world of miniaturized systems, a reliable microfluidic pump with low maintenance is not just a convenience, but a necessity. This blog explores the reasons why individuals and industries seek such pumps and offers insights as to why Fluid Metering pumps require little to no maintenance.

The Need for Low-Maintenance Microfluidic Pumps:

Precision in Fluid Handling

Microfluidic systems demand precision, especially when dealing with small volumes. Low-maintenance pumps ensure consistent and accurate fluid delivery over extended periods, reducing the need for constant adjustments.

Time and Cost Efficiency

In research, development, or industrial processes, time is of the essence. Low-maintenance microfluidic pumps minimize downtime and decrease the need for frequent maintenance, allowing for continuous, efficient operations. This, in turn, contributes to cost savings.

User-Friendly Operation

Many microfluidic applications are operated by researchers and technicians with varying levels of expertise. A pump that requires minimal maintenance simplifies the user experience, making it accessible to a broader audience without compromising on performance.

Choosing the Right Low-Maintenance Microfluidic Pump:

Many factors need to be considered when choosing the right low-maintenance microfluidic pump. The types of fluids your application requires could affect the material compatibility of the pump. The flow rate and pressure requirements of your application also need to be assessed.

Evaluate the size and form factor of the pump, ensuring it can seamlessly integrate into your existing microfluidic setup. A compact design is often preferred, especially in environments where space is a constraint.

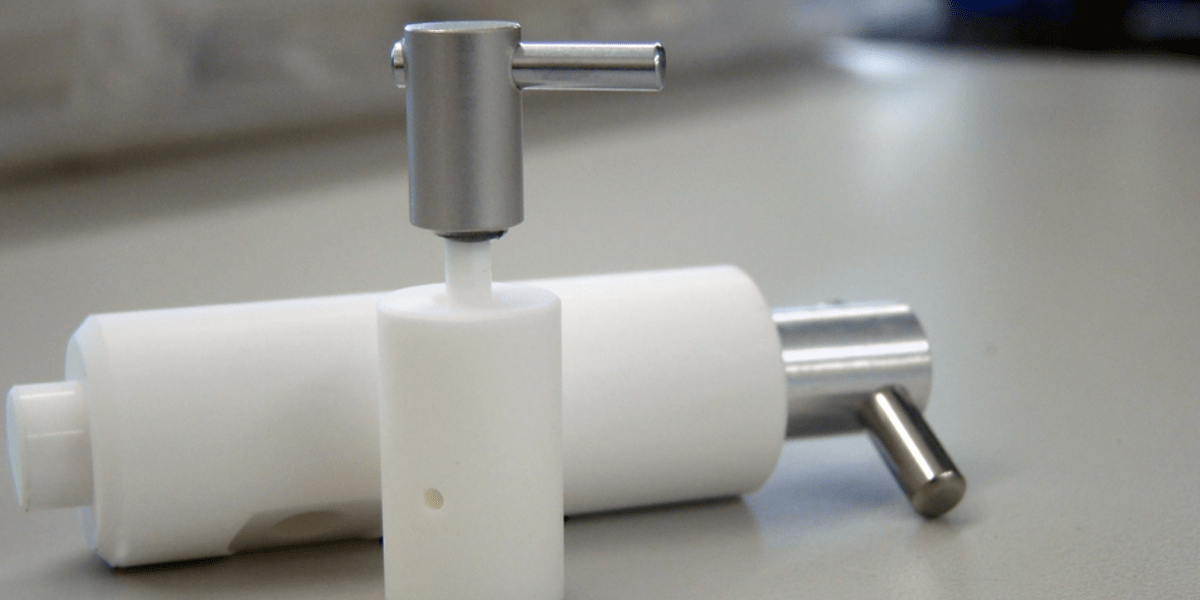

In the dynamic realm of microfluidics, a low-maintenance microfluidic pump emerges as a critical component, offering precision, efficiency, and reliability. By understanding the specific needs of your application and carefully selecting a pump with the right features, you can unlock the full potential of microfluidic systems while minimizing the burden of regular maintenance. Fluid Metering pumps are compact and offer a wide array of chemically compatible materials. Our core technology, a rotating, reciprocating, piston pump, has only one moving part, allowing for little to no maintenance over an extended period of time. With our unparalleled precision and efficiency, Fluid Metering heralds a future in microfluidics where reliability is maximized, and maintenance concerns are minimized.

1 min read

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

1 min read

Key Takeaways: Fluid Metering’s precision pumps for silica bead slurries handle particle sizes from 3µm to 800µm with low shear, no entrapment, and...

Key Takeaways: For valveless piston pumps vs. diaphragm pumps, Fluid Metering’s CeramPump® technology offers superior precision, clog resistance,...