1 min read

How Can I Meter Different Fluids at Different Flow Rates?

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...

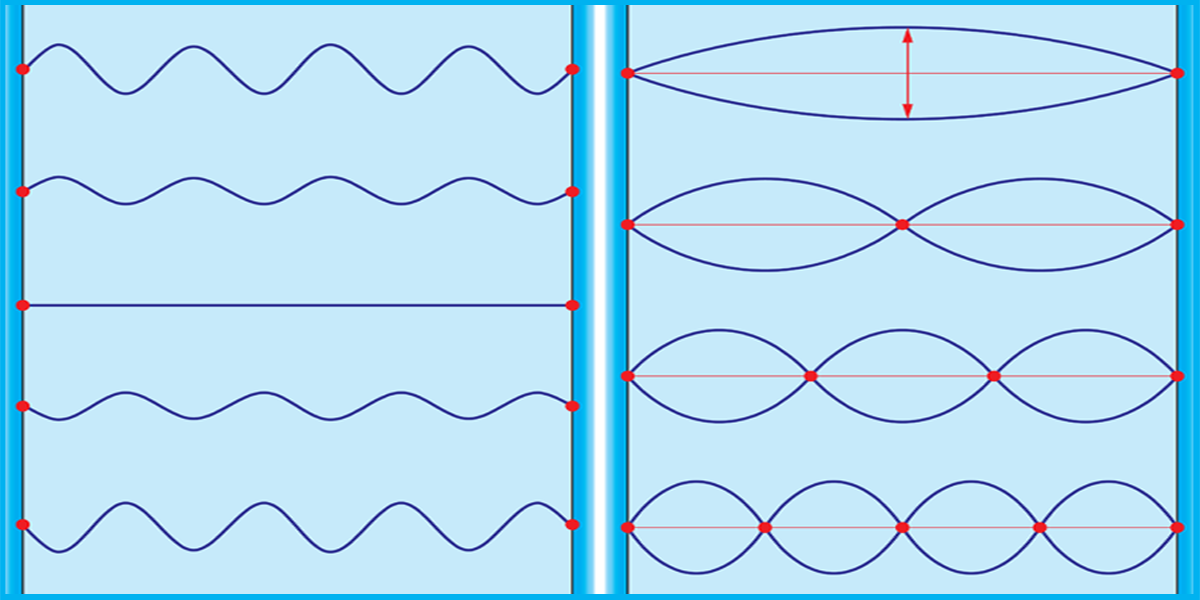

Pulsation refers to the periodic variation in flow rate within a fluidic system. It can be graphically interpreted as the difference between peaks and troughs compared to a nominal flow. Within microfluidic pump setups, pulsation can arise due to various design and operational factors. This can lead to fluctuations in the flow rate which may significantly affect the stability and accuracy of microfluidic processes.

Causes of Pulsation

Pulsation derives from multiple sources within a given system. While these individual sources may, in certain cases, cancel each other out, they can also collectively augment pulsation.

Mechanical Action: The mechanical actions of certain pumps, like peristaltic pumps, involves cyclic compression and relaxation of tubing, which naturally introduce pulsation.

Pressure Variations: In pressure-driven systems, variations in the applied pressure can cause pulsatile flow, especially if the pressure source is not perfectly stable.

Pump Head and Drive: The pump head plays a crucial role in determining the extent of pulsation. For instance, FENYX® Variable Dispense Pump’s flow profile is closely tied to the pump head and slightly affected by the drive mechanism.

System Design: Complex tubing systems with bends, restrictions, and diameter differences can amplify pulsations.

Impacts of Pulsation

Controlled pulsation offers several benefits to the following processes:

Improved Mixing: Pulsatile flows improve mixing by creating variations in velocity and shear stress over time, leading to a more uniform mixture.

Droplet Generation: The oscillatory nature of pulsatile flows helps in the precise generation of droplets, which is essential for processes like emulsification and encapsulation.

Clog Prevention: By periodically changing the flow dynamics, pulsatile flows can help prevent clogging in microchannels, dislodging particles that might cause blockages.

Enhanced Cell Cultures: In biological applications, pulsatile flows can mimic natural physiological conditions, promoting the growth and viability of mechanosensitive cells, which is beneficial in tissue engineering bioreactors.

Particle Manipulation: The time-dependent nature of pulsatile flows allows for accurate manipulation of particles, aiding in tasks such as cell sorting and filtration.

Bioassay Automation: Pulsatile flows provide consistent and repeatable conditions, enhancing the automation and reliability of bioassays.

Unchecked pulsation can lead to hefty issues such as:

Flow Instability: Fluctuations in flow rate can cause instability in processes that require a steady flow, such as continuous cell sorting or chemical reactions.

Measurement Errors: In analytical applications, pulsation can introduce noise and errors in measurements, affecting the accuracy of results.

Reduced Lifespan: Additional unaccounted vibrations or stresses can lower the lifespan of the system, which is partially calculated based on expected wear.

To highlights the importance of minimizing pulsation for accurate measurements, consider particle counting. The main goal in particle counting is to pass media through a controlled area and observe what passes through. The more the media constantly bounces back and forth through that zone, the more difficult it is to determine if each particle passed through or not.

Strategies to Mitigate Pulsation

To minimize the adverse effects of pulsation, several system-dependent strategies can be employed:

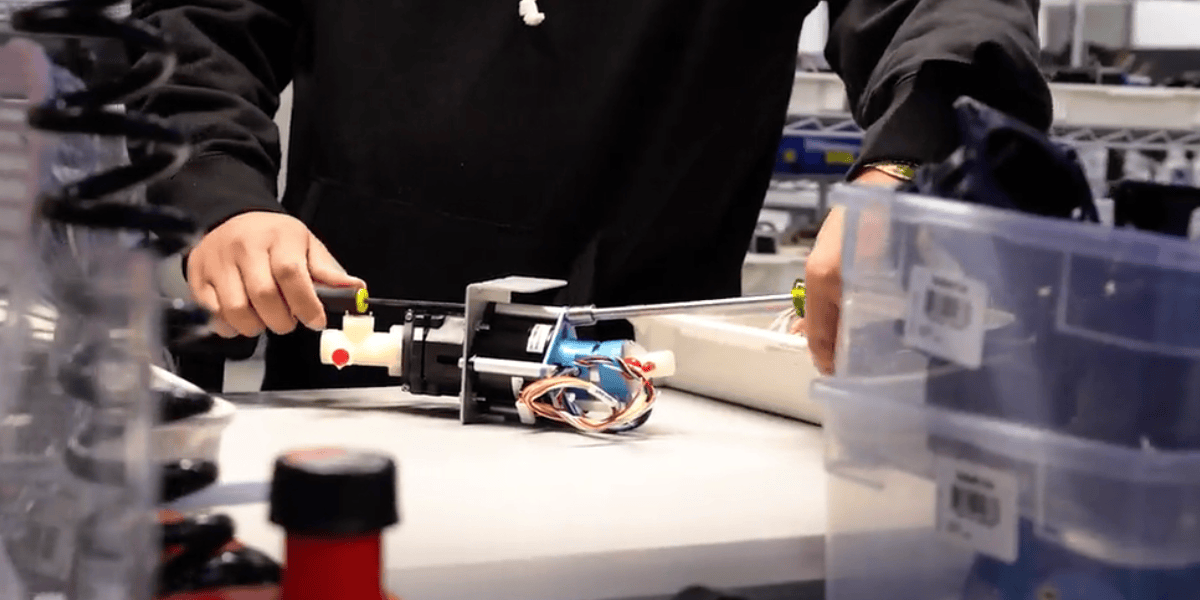

Dual Pump Systems: Using two pumps operating out of phase can help cancel out pulsations, leading to a more stable flow. This can be accomplished using two separate pumps or Fluid Metering’s Duplex Pump.

Optimized Pump Design: Less complex systems with less moving parts, such as our CeramPump® valveless technology, aid in minimizing pulsation.

Tubing: Generally, using longer, softer tubing can help in reducing pulsations. The length of the line can be increased incrementally until the desired flow profile is reached.

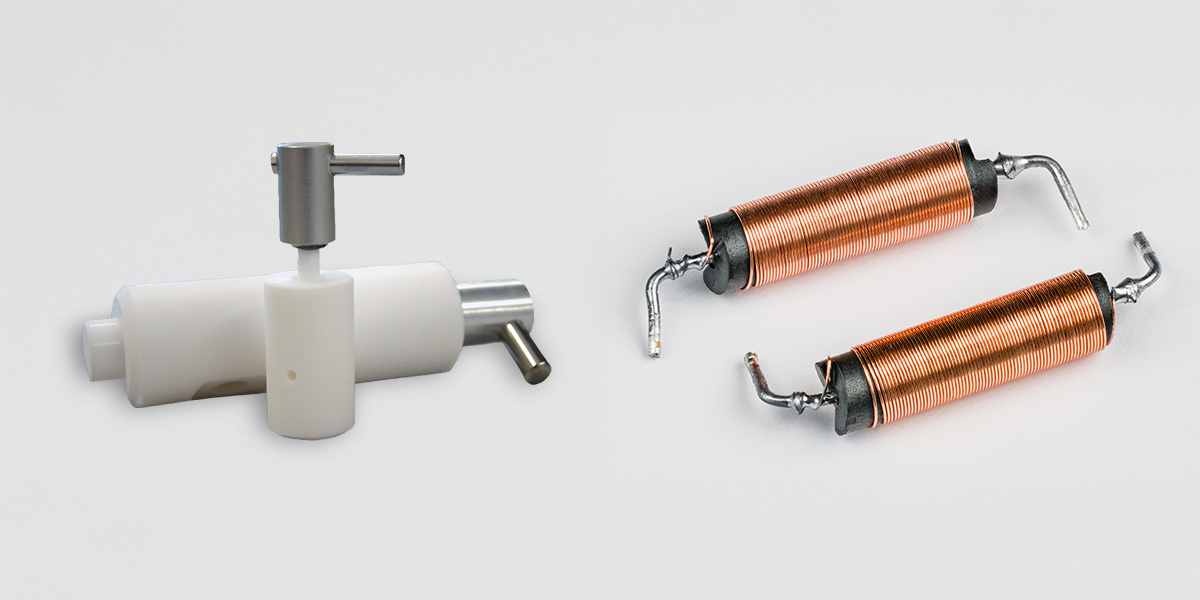

External Dampeners: Pulse dampeners can be used to effectively reduce pulsations. The bellow-shaped structure of Fluid Metering’s Pulse Dampener cuts pulsation down to below 10% alone.

Above Image: Fluid Metering’s Pulse Dampener

Varying Motor Speed: Adjusting motor speed can achieve a smoother flow for short dispense periods, a technique known as “Fluid Metering Smooth Flow”.

Combining Methods: By properly combining the aforementioned techniques, pulsation-induced flow deviation can be reduced to less than 1%.

Understanding and managing pulsation in microfluidic pumps is crucial for optimizing the performance of microfluidic systems. By leveraging our advanced pump designs and employing effective mitigation strategies, your team can harness the benefits of pulsatile flow while minimizing its drawbacks. Contact us today to solve your pulsation puzzles!

1 min read

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...

1 min read

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

Key Takeaways: For precision fluid delivery vs. solenoid pumps, Fluid Metering’s valveless piston pumps outperform in accuracy, reliability, and...