1 min read

Guidelines for Pumping High Viscosity Fluids

Key Takeaways: Fluid Metering’s high-viscosity fluid pump solutions support thick, slow-moving liquids by using larger tubing, low RPM operation,...

When it comes to selecting the correct pump for your application, there are several factors that need to be considered, one of which is the viscosity of the fluid. In this post, we'll discuss why viscosity is an important variable and how to optimize a pump for your fluid. Here's a look:

When a user is searching for a new pump, there are typically 3 variables that should be considered: flow rate, fluid viscosity, and headloss. These 3 variables play a key role and will affect your fluidic control system, with viscosity being one of the key variables that could limit the pump’s operation.

Viscosity helps define the makeup of a liquid or fluid. For instance, a high viscosity fluid is defined as one that flows slowly, while a low viscosity fluid is one that flows readily — and it's this makeup that can impact a pump's internal pressure and ultimately change how efficiently it can operate.

For example, if you want a high flow rate but you're working with a high viscosity fluid that flows slowly, you may need to look beyond just a standard pump and instead opt for one with larger tubing that can better support the fluid and your flow rate goals. If you don't, the backpressure could become too great and the pump won't perform as you intend it to. Conversely, if you're working with a high viscosity fluid and don't require a high flow rate, then this backpressure likely doesn't become an issue.

When it comes to viscosity, the main goal is to find the right balance between the pump you're using and the system you're developing.

Just because you're working with a low viscosity liquid doesn't necessarily mean that you don't have to be concerned. As we noted in the previous section, it's all about finding the right balance between a pump that has the flow rate and dispensing capabilities you need and making sure the pump can accurately and precisely deliver the fluid when integrated into an instrument. It's important to ask the right questions and know exactly what you're looking for as you come to your decision.

Analytics and diagnostic applications typically work with low viscosity fluids, while industrial applications where pumps are used in manufacturing environments typically process higher viscosity fluids. Even with low viscosity fluids, tubing sizes and other restrictions need to be properly selected. With high viscosity fluids, larger tubing and higher torque may become necessary. But keep in mind that any variable that is changed can have an impact on another aspect of the pump.

The bottom line is that you don't want to overlook viscosity of any type when you're making a decision on a pump. Be sure to utilize the expertise of professionals associated with the pumps that you're considering to help find the perfect instrument.

Motor oil, gels, and more are all examples of fluids that tend to have high viscosity. People are often concerned that processing a high viscosity fluid means that the pump they use will have a shorter life span, but that is not necessarily the case. It all comes down to variables like downstream restrictions, flow rate, backpressure, and more. Additionally, if you're able to heat the fluid so that it flows more easily, that can be significant.

High viscosity fluids tend to only become a problem when you're pushing a pump to its limits, which is why it is so important to talk with an expert when choosing your pump. They can help work through the requirements and make sure the correct elements are present in the chosen pump to accomplish the desired goals and not push the pump to its limits.

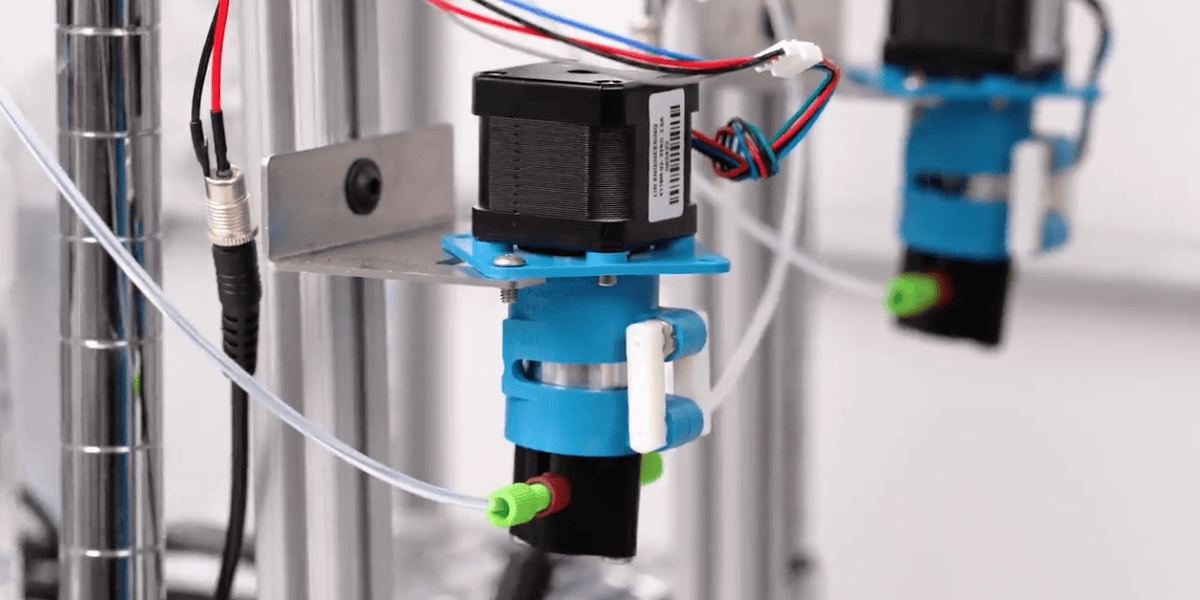

One of the benefits of Fluid Metering pumps as it pertains to viscosity is how versatile they are. As we've noted throughout this piece, we highly recommend consulting an expert to help you select the right pump for your application.

Fluid Metering's portfolio of pumps is highly configurable and can be adjusted to just about any application to ensure the user's expectations are met. Fluid Metering has a long history of expertise when it comes to pairing the right pump with the right application.

You might think that it's an easy task determining the viscosity of your fluid and how it will perform in a pump, but we'd encourage you to reach out to our knowledgeable team to confirm your hypothesis. At Fluid Metering, our experts will take the time to learn about your application in detail, determine what you're trying to achieve, and make sure all relevant factors are being considered.

Remember, viscosity is just one piece of the puzzle when it comes to selecting the right pump, and adjusting certain variables will have an effect on others. It's all about finding that perfect balance.

For more information on viscosity and how it relates to how a pump performs, reach out to Fluid Metering today.

1 min read

Key Takeaways: Fluid Metering’s high-viscosity fluid pump solutions support thick, slow-moving liquids by using larger tubing, low RPM operation,...

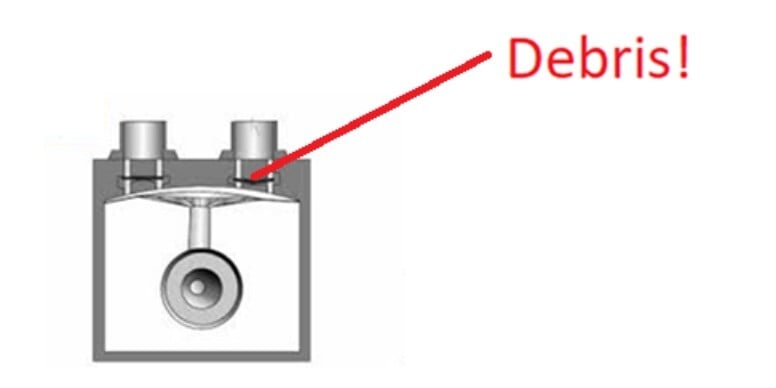

Key Takeaways: Traditional waste pumps in IVD systems are prone to clogging and failure, especially when handling viscous fluids, debris, or...

1 min read

Key Takeaways: Fluid Metering’s high-speed, high-pressure pump solutions—including the QD, QBLDC, and STF series—are designed to handle...