1 min read

Configuring a Pump for Non-Contact Dispensing

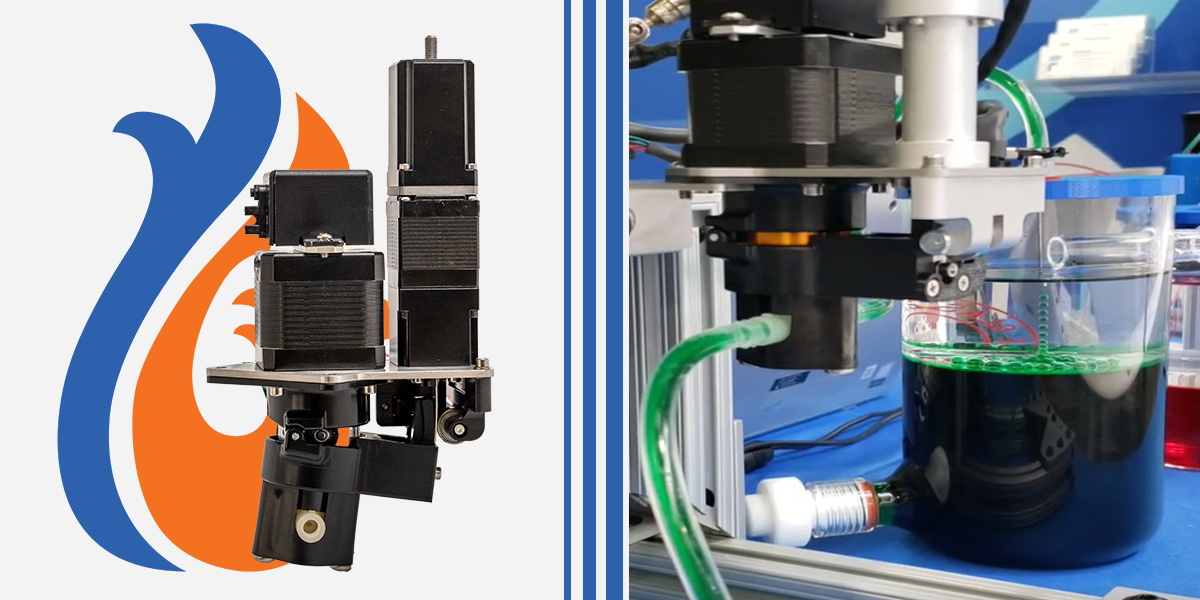

Key Takeaways: Fluid Metering’s FENYX® pump for non-contact dispensing enables accurate, sterile fluid delivery under 10 µL without tip submersion...

Until recently, non-contact dispensing has rarely been embraced as a viable fluid control method. Yet, as industries strive for greater precision, efficiency, and sustainability, non-contact dispensing is emerging as an advanced alternative to previous dispensing techniques. Let’s decant the differences and advantages of non-contact dispensing.

Contact vs. Non-Contact Dispensing

Contact Dispensing involves the tip or nozzle either touching off on the substrate/dispensing surface or submerging into the fluid being dispensed.

Non-Contact Dispensing delivers fluid by expelling it from the tip or nozzle without requiring the tip/nozzle to touch off on the substrate or submerge into the fluid.

Key Advantages of Non-Contact Dispensing

Reduced Contamination Risk: The traditional practice of contact dispensing carries a significant risk of contamination transfer. By avoiding direct contact altogether, non-contact dispensing minimizes the risk of cross-contamination, ensuring cleaner and more dependable results.

Environmental Benefits: Contact dispensing relies on disposable tips, leading to material waste and increased costs, or stainless steel nozzles that require thorough washing between each reagent or test cycle. Non-contact dispensing reuses the same tip and lessens the need for frequent nozzle washing, supporting environmental, social, and governance (ESG) goals. This later approach aligns with green-friendly initiatives, making it a preferred choice in regions with stringent environmental regulations, such as the E.U. It could also be the future go-to solution in other areas, like the U.S.A, as new related legislation is passed each year.

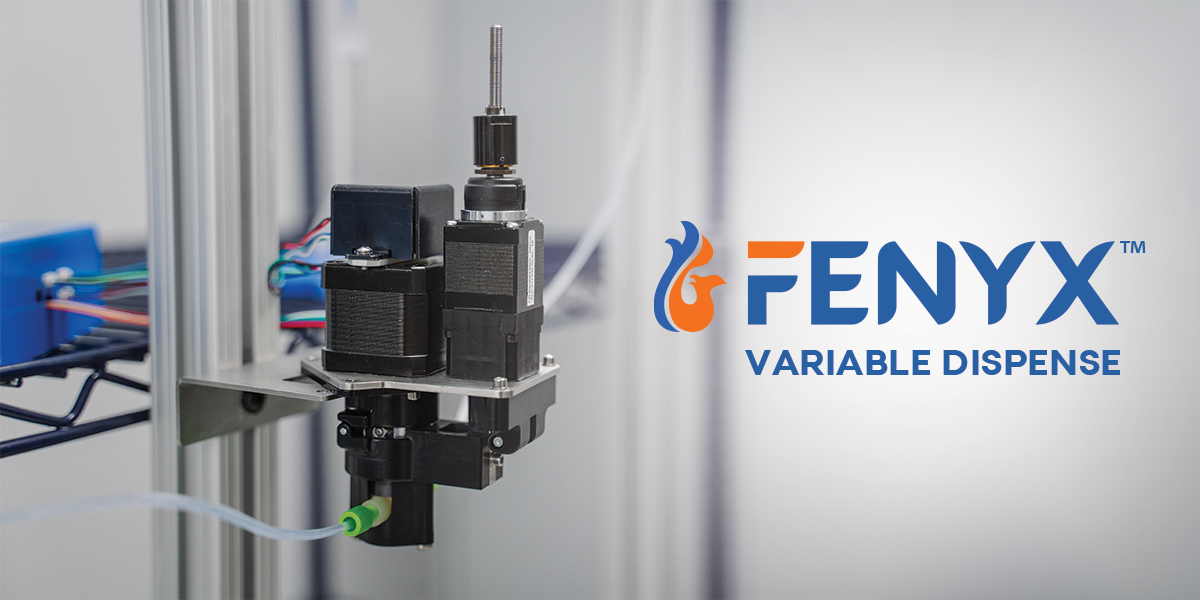

Improved Precision and Repeatability: Due to the nature of expelling liquid through the air and its tendency to splash or create satellite drops, past non-contact systems have strayed from achieving desired results. However, recent advancements have addressed these precision and accuracy challenges. Technologies like Fluid Metering’s FENYX® Variable Dispense and TRYTON™ Pulseless Nanoliter pumps feature complete shearing, creating clean breaks that prevent satellite drops and enhance system reliability.

Higher Throughput: Non-contact dispense pumps operate faster as they cut back on nozzle washing time and eliminate the need for tip changes, enabling significantly increased throughput.

Benefiting Applications and Industries

Non-contact dispensing is particularly beneficial in diagnostics, in-vitro diagnostics (IVD), and biotechnology. These fields demand high precision at microscales and no contamination, making non-contact dispense systems ideal. Avoiding contact also reduces the disturbance and damage of delicate biological samples.

Advancements in Non-Contact Dispensing Technology

The latest advancement, the FENYX pump, utilizes positive displacement and the inertia of matched piston liners to achieve unparalleled precision. Unlike time pressure dosing (a type of pneumatic dispensing which can be easily affected by many variables like air pressure, humidity, and temperature), the FENYX offers a robust and reliable solution for precise microliter volume dispensing.

Choosing the Right Dispensing Method

When selecting between contact and non-contact dispensing, consider your throughput requirements and the importance of contamination risk reduction. Non-contact dispensing offers a faster, cleaner, and more sustainable solution for the future of fluid handling. With numerous advantages and ongoing technological advancements, it is poised to become the standard for precision fluid handling across a myriad of industries. Contact us today to experience the benefits of more efficient fluid applications.

1 min read

Key Takeaways: Fluid Metering’s FENYX® pump for non-contact dispensing enables accurate, sterile fluid delivery under 10 µL without tip submersion...

1 min read

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump vs. syringe pumps delivers 10x–40x faster throughput, ±0.5% precision, and...

Key Takeaways: The FENYX® Variable Dispense Pump Development Kit offers OEMs a complete, plug-and-play solution for rapid microfluidic prototyping,...