1 min read

Selecting a Pump for Polymerase Chain Reaction (PCR) Applications

Key Takeaways: For PCR and ddPCR pump selection, Fluid Metering’s FENYX® Variable Dispense Pump offers precise flow control, low pulsation, and...

4 min read

Blake Webb : Updated on November 4, 2025

In the world of life sciences, engineers are all facing pressure to increase throughput and decrease total cost of ownership. Common types of pumps for dispensing systems are syringe pumps or inline piston pumps which are slow and require maintenance over the life of the pumps to achieve a satisfactory throughput. Fluid Metering has now developed FENYX - a breakthrough variable dispense pump that can be used in place of most syringe pump applications to increase throughput and decrease costs.

Fluid Metering’s CeramPumps® have been used for over 60 years in the life sciences industry and, until now, have been limited to precision dispensing with a fixed volume. FENYX Variable Dispense pump enables users to change the dispense volume, similar to a syringe pump or inline piston pump, but with all the added benefits of using a ceramic rotating reciprocating piston.

FENYX® vs. Syringe Pump

FENYX is a perfect drop-in replacement for syringe pumps at OEMs desiring high uptime and zero maintenance. For those contemplating including a syringe pump in their design, FENYX addresses the following concerns:

High Maintenance = High Cost of Ownership

Problem – Over time, syringes start to wear, causing a decline in volumetric and positional precision and accuracy. Syringe pumps typically need to be serviced after 100-250K cycles which, depending on your duty cycle, might mean you need replacement parts every few weeks to every few months. Even if the syringe pump is replaced entirely, recalibration could also be necessary. All of these maintenance requirements result in high extra costs and large losses in working time.

Solution – FENYX has a maintenance free rotating reciprocating piston design. Its ceramic components are both chemically inert and dimensionally stable, so they will not distort, stretch, or change shape over time. With only one moving component, FENYX undergoes little to no wear, making it maintenance free for the lifetime of the instrument.

Expensive Supporting Fluidics

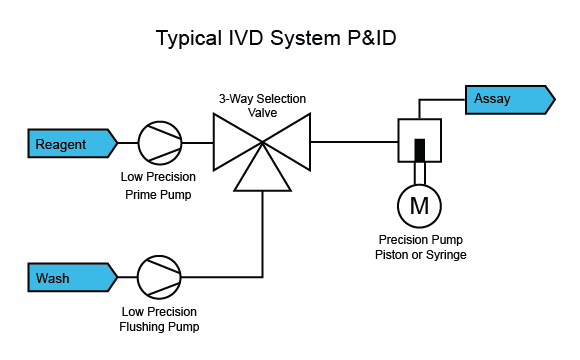

Problem – Typically OEMs must include expensive supporting fluidic architecture to keep throughput high. A typical P&ID might look like this:

Requiring separate pumps to prime, flush, and dispense means additional lines of frail tubing, more risky leak points, and increased OEM machine size.

Solution – FENYX is valveless and capable not only of self-priming, but also of priming 10x-40x faster than a syringe pump. This design helps OEMs eliminate unnecessary fluidic components like prime pumps, flushing pumps, selector valves, and tubing - FENYX replaces it all!

Challenges Priming Low Volumes Syringes

Problem – Syringe pumps trap substantial amounts of air between the tip of the syringe and the valve. For small volume syringe pumps, this air can only be removed through multiple priming cycles which slows down the priming process and creates unwanted delays in time-sensitive applications. Syringe pumps also require a separate pump to prime.

Solution – FENYX can be rapidly self-primed at higher dispense volumes and then be adjusted to the target dispense. This eliminates bubble entrapment and fixes the priming issues found with smaller syringe barrel sizes.

Restrictions with Flow and Viscous Mediums

Problem – Since syringe pumps operate by exerting linear force on a plunger to dispense fluid, highly viscous mediums cannot be handled. Creating more intense friction than the pump can overcome, viscous fluids quickly lead to pump degradation and failure. Even with lower viscosity fluids, the syringe pump’s flow rate is constricted, being fully dependent on the syringe diameter.

Solution – FENYX Variable Dispense pump is designed with more robust components and can be equipped with more powerful motors, allowing it to overcome the resistance needed to handle a wider range of fluid viscosities without performance degradation. Drawing fluid from a reservoir as need, its flow rate can operate continuously at a wider range, spanning from 1mL/min at 1RPM all the way to 400mL/min at 1,000RPM.

Non-Contact Dispensing

Problem – Syringe pumps lack non-contact dispensing capability, necessitating life science OEMs to resort to touch off or submersion methods for dispensing single microliter volumes. This requires frequent probe tip changes or washing to prevent cross-contamination, reducing throughput and increasing costs.

Solution – FENYX Variable Dispense pump offers non-contact dispensing capability down to 4µL with exceptional precision and accuracy. This eliminates the need for probe tip changes or washing, reducing system costs and enhancing throughput for life science OEMs.

Improvements

Syringe pump improvements can only go so far, but variable dispense pumps are designed for flexibility. FENYX includes several new improvements from its precursive FVD model including:

1. Calibratable flag - updated home positioning and dispense

2. Anti-backlash mechanism

3. Encoder – electronic piece of equipment

4. Sensor orientation

5. Internal spring steel that connects the variable head to the actuator

6. The linear sensor is dual mounted

Applications

When continuous operation and quicker, more accurate, more reliable results are needed, FENYX is the ultimate long-term solution. Plus, it will provide a more diverse array of applications than a syringe pump is limited to. Typical applications you can find our CeramPump® technology in today include:

Ready to relinquish avoidable worries and unreliable fluidic tech to the ashes of time? Light your path to the latest innovation reawakening with a 90-day free trial1 of the FENYX Development Kit.

1 Approval of the development kit trial is contingent upon an internal review by the Fluid Metering team. Applications may be denied based on the details provided in the application or during follow-up discussions.

1 min read

Key Takeaways: For PCR and ddPCR pump selection, Fluid Metering’s FENYX® Variable Dispense Pump offers precise flow control, low pulsation, and...

1 min read

Key Takeaways: Fluid Metering’s FENYX® pump for non-contact dispensing enables accurate, sterile fluid delivery under 10 µL without tip submersion...

Key Takeaways: In precision microfluidic dispensing systems, trapped air can cause wide variation in dispense volumes and compromise...