Impact of Air and How to Evacuate it From a Fluidic System

Key Takeaways: In precision microfluidic dispensing systems, trapped air can cause wide variation in dispense volumes and compromise...

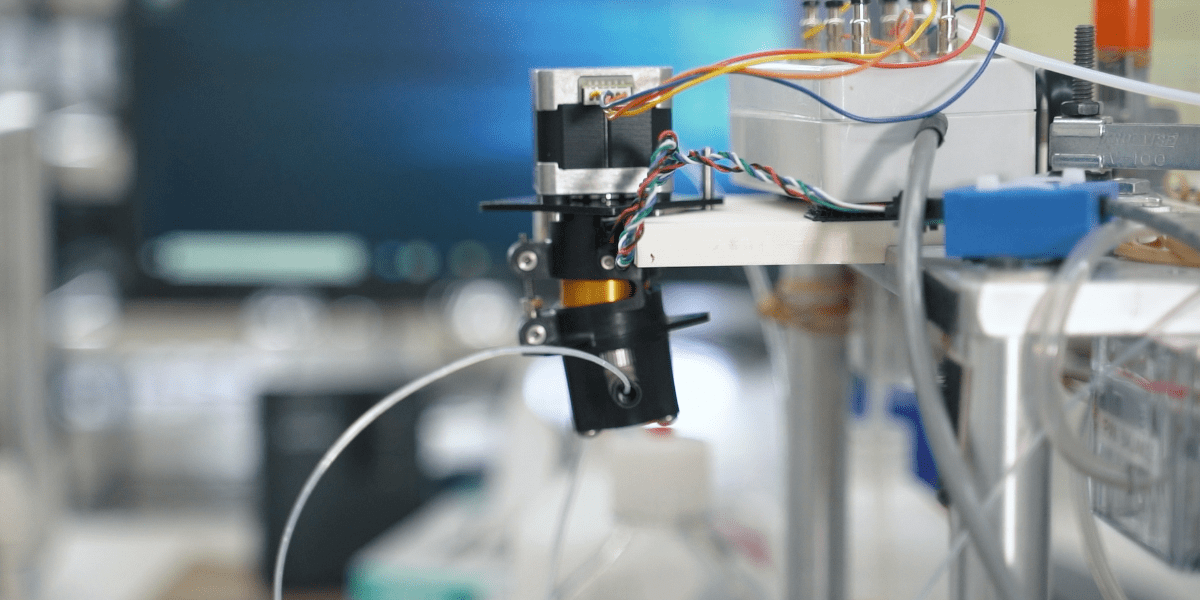

As an engineer, having a way to dispense fluids through a non-contact tip in medical diagnostic and other devices could potentially be not only life changing, but life-saving. The current options for dispensing require contact- mostly consisting of a submerged tip or use of the touch off method. Neither of these options are desirable due to either cross contamination possibility, non-repeatability, or lack of accuracy. An ideal method to solve this issue would be a pump with non-contact dispensing capabilities.

Solutions to dispensing a small amount of fluid (typically less than 10 microliters) have previously been few and far between, aside from the limited options listed above. You are probably looking for a better pump solution that allows you to dispense fluids in an accurate and sterile way.

Fluid Metering's Solution to Non-Contact Dispensing

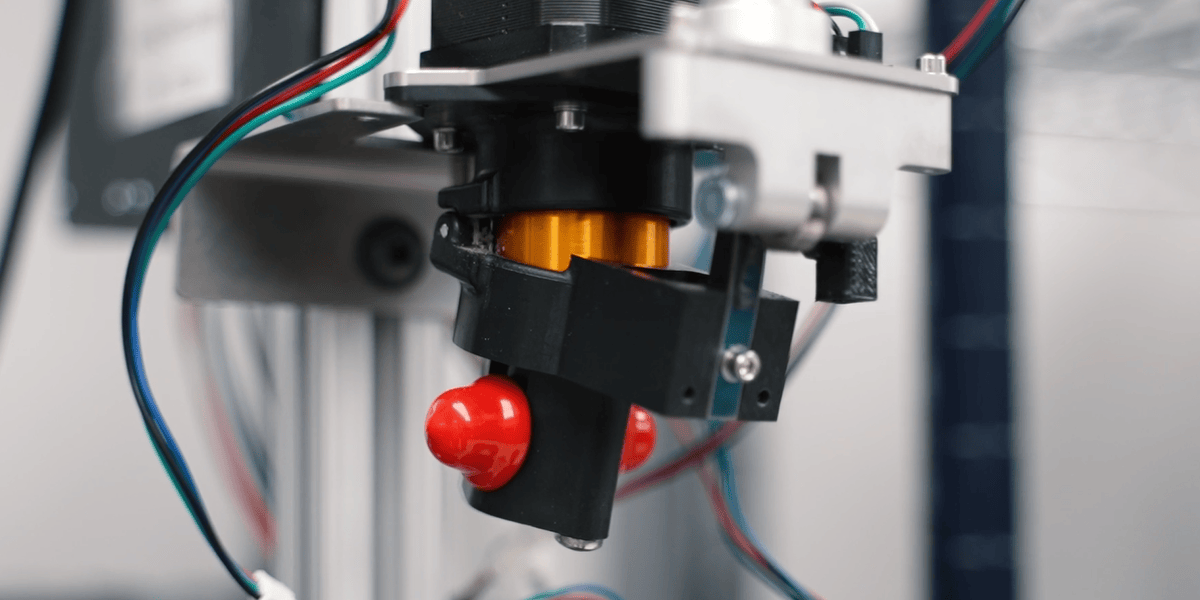

Fluid Metering's patent pending non-contact dispensing methodology suspends the tip over air and still accurately and precisely dispenses small amounts of fluid, making sure the fluid breaks away cleanly, repeatably, and to the desired location.

This is especially beneficial for medical devices, such as diagnostics which might need to dispense a fluid to start a reaction. The non-contact dispense method produces a result that is very accurate in a specific location to interact with the desired media and provides the level of delicacy needed for these types of devices.

This non-contact dispensing methodology can be used in various other pieces of medical devices as well. Fluid Metering developed this methodology to be able to get to the outcome of non-contact dispensing and can work with you to incorporate it into your machine.

How Would We Implement This in Your Device?

There are four main areas we look at when implementing non-contact dispensing into a device:

Tip

Tubing

Pump Motor

How the Pump Head is Primed

Learn More About How Fluid Metering Can Help

At Fluid Metering, we believe that you shouldn't have to sacrifice for less than the best, which is why we created the non-contact dispense methodology to be used in dispensing less than 10 microliters of fluid.

Our experts will be there through every step of your journey to help you select the right pump and tip for your individual needs. Here is how we can help:

Our FENYX® Variable Dispense Pump (formerly FVD) is recommended for non-contact dispensing.

.gif?width=172&height=306&name=FVDPumpGif%20(1).gif)

To get started developing your solution with Fluid Metering, contact us today.

Key Takeaways: In precision microfluidic dispensing systems, trapped air can cause wide variation in dispense volumes and compromise...

1 min read

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump vs. syringe pumps delivers 10x–40x faster throughput, ±0.5% precision, and...

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for ISO:13485 medical devices simplify fluidic architecture by combining priming,...