1 min read

Configuring a Pump for Non-Contact Dispensing

Key Takeaways: Fluid Metering’s FENYX® pump for non-contact dispensing enables accurate, sterile fluid delivery under 10 µL without tip submersion...

3 min read

Richard Hill : Updated on October 28, 2025

If you are trying to dispense tiny amounts of fluid (typically 10 microliters or less), accuracy is one of the most crucial elements you need in a fluidic system. If your pump is consistently imprecise, you will see dispense volumes widely scattered around your desired target.

While these numbers tend to average out to the desired accuracy, that variation in actual dispenses is not acceptable to you when you are counting on your pump system to dispense with an accuracy of +/- 1%. Diagnosing and fixing this issue can be problematic when you are unsure of the cause - where do you look?

Signs of Air in Your System

When small inaccuracies like those mentioned above occur, oftentimes the cause is air trapped in the system. This is detrimental to achieving the desired accuracy needed. Air has a significant impact on the coefficient of variation, an indicator of the precision of the pump.

When operating the pump, any trapped air could move around - it might work its way out of the system, or it could move to a different part of the system. Additionally, the air could expand and contract during any fluidic movement, acting as a cushion and causing further fluctuations at the dispense site. Here are two indications there is air trapped in the system causing inaccuracies:

Anyone that incorporates a pump into their system would need to eliminate air, but this evacuation is especially in situations in which discreet, small volume dispenses are required, such as laboratory situations, assembly, or production lines.

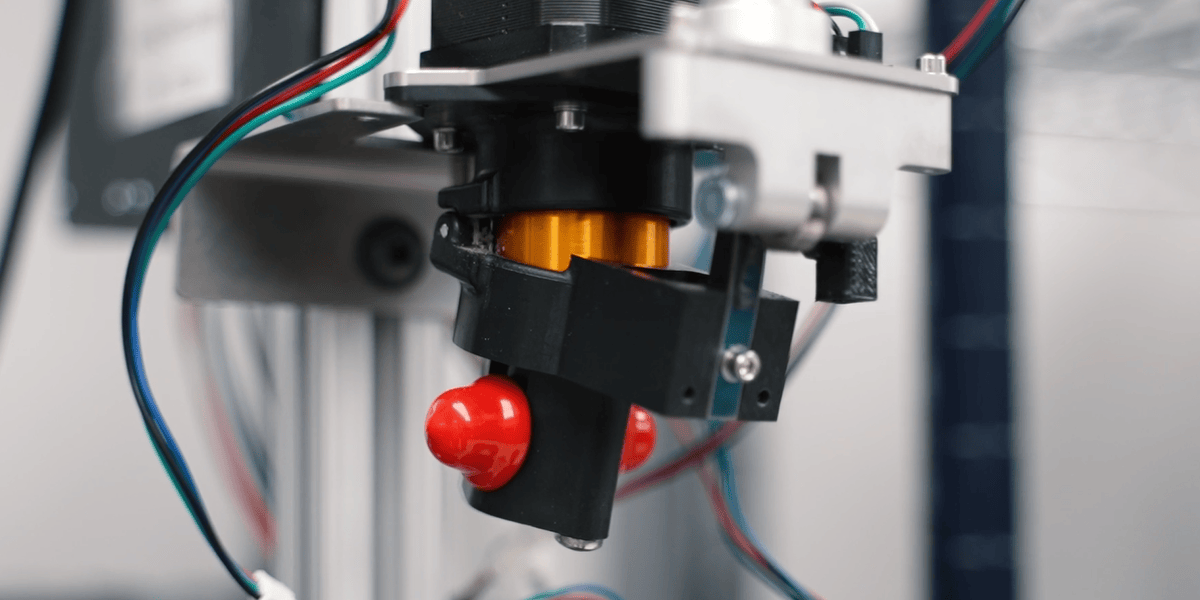

How to Evacuate Air from Your FENYX® Variable Dispense Pump System

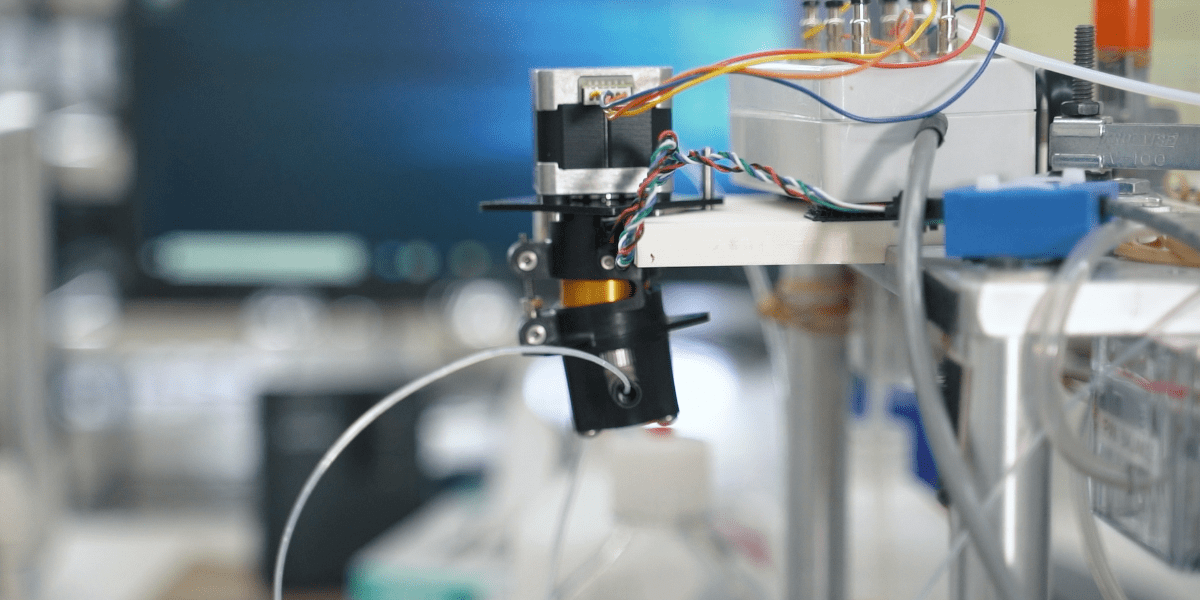

Fluid Metering’s FENYX Variable Dispense Pump (formerly FVD) is often one we recommend for discreet, small volume dispenses due to its ability to change dispense volumes all within the same system. However, if you are seeing inaccurate dispenses, this can be frustrating. At Fluid Metering, we are typically able to quickly diagnose if the lack of precision from your system is due to trapped air and would provide the following solutions for effective evacuation of the air.

Proper priming of the pump is essential for removing air. FENYX Variable Dispense Pump allows different speeds and dispense volumes all within the same system, which makes priming to evacuate air an extremely effective solution.

The proper steps to evacuate air from FENYX Variable Dispense Pump would be:

Large dispenses at slow speeds are most effective at getting the air out of the pump head itself. To remove air from the tubing, a smaller dispense at a faster rotation will cause agitation that is necessary to dislodge air bubbles to effectively prime. The benefits of FENYX Variable Dispense pump is that the dispense volume and speed can be changed to take into account these differences between priming cycles to clear pump heads vs tubing.

How Fluid Metering Can Help

We often find users with FENYX Variable Dispense Pump who are struggling with inaccurate dispense volumes are noticing trends of numbers getting smaller or larger with no other changes to the system. Our technical experts can quickly determine the cause of trapped air and are able to provide a recommended solution.

If you are looking for a fluidic system to dispense small volumes of less than 10 microliters, Fluid Metering has an industry leading amount of precision in our pumps. We hold ourselves to an accuracy standard of approximately 0.5% C.V. (Coefficient of variation), but this is dependent on dispense volume. For example, FENYX Variable Dispense Pump is capable of dispensing at small volumes of less than 10 microliters with a C.V. of less than or equal to 1%, while simultaneously holding a C.V. of less than 0.5% when dispense volumes are greater than 10 microliters.

Our technical experts can help determine if FENYX Variable Dispense Pump is the right solution for you. To learn more or contact us today so our technical experts can tailor a fluidic solution to your individual needs.

1 min read

Key Takeaways: Fluid Metering’s FENYX® pump for non-contact dispensing enables accurate, sterile fluid delivery under 10 µL without tip submersion...

1 min read

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump vs. syringe pumps delivers 10x–40x faster throughput, ±0.5% precision, and...

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for ISO:13485 medical devices simplify fluidic architecture by combining priming,...