1 min read

Selecting a Pump for Polymerase Chain Reaction (PCR) Applications

Key Takeaways: For PCR and ddPCR pump selection, Fluid Metering’s FENYX™ Variable Dispense Pump offers precise flow control, low pulsation, and...

Key Takeaways / Highlights

Precision Flow: Fluid Metering Pumps Powering Battery Manufacturing Innovation

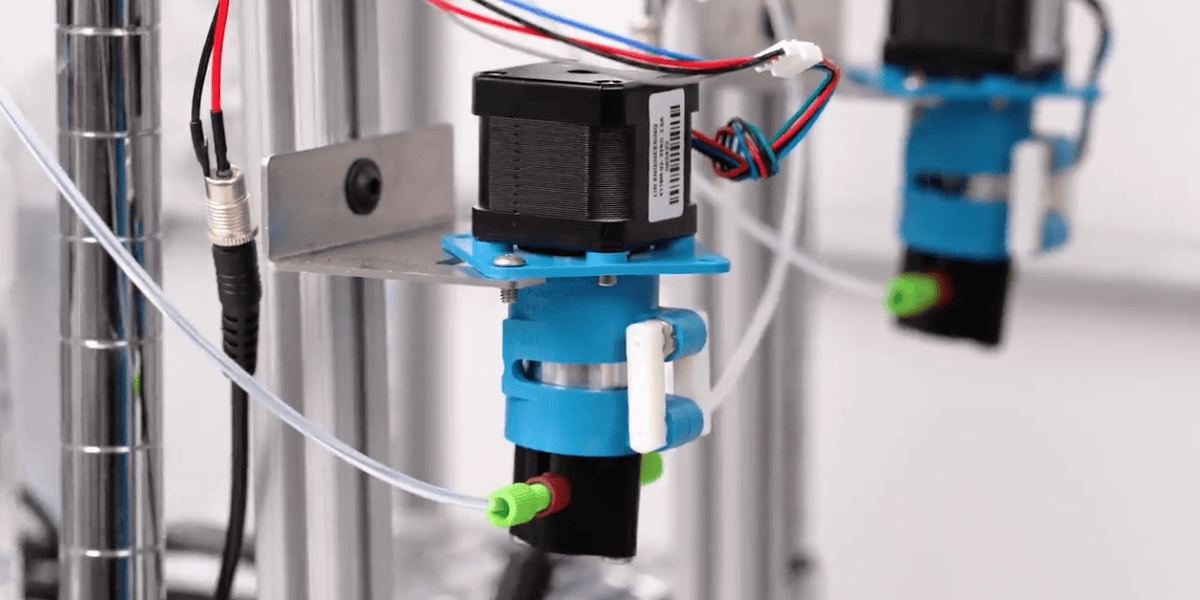

The relentless growth of the electric vehicle (EV) and portable electronics markets has placed a growing demand on battery manufacturing. At the heart of efficient and high-quality battery production lies the precise handling and dispensing of critical chemicals. This is where Fluid Metering pumps excel, offering indispensable solutions for a range of applications within the battery manufacturing process.

Pumps play a pivotal role in numerous stages of battery production. As is well-documented in industry best practices, their accuracy directly impacts the final product's performance and longevity. Fluid Metering is proud to offer pumping solutions specifically tailored to the demanding needs of battery manufacturers, particularly in:

Electrolyte Manufacturing: The electrolyte is the lifeblood of a battery, facilitating the essential chemical reactions that enable energy storage and release. Fluid Metering pumps provide the precise dosing required for mixing electrolyte solutions, often containing chemicals like sulfuric acid, ensuring consistent concentration and quality batch after batch. Our valveless piston technology delivers high +/- 1% accuracy and +/-0.5% precision, guaranteeing repeatable transfer that is critical for this vital stage.

Cathode Material Manufacturing: The performance of a battery is significantly influenced by the quality of its cathode material. The production of these materials often involves the precise metering of various chemical precursors. Fluid Metering pumps deliver the accuracy needed for consistent chemical control in these complex processes, contributing to the creation of high-performing cathode materials.

Electrolyte Injection: The final step of filling the battery cells with the electrolyte demands absolute precision. Overfilling or underfilling can lead to performance issues and safety concerns. Fluid Metering's unique valveless and airtight design provides the fine-tuned control necessary for accurate electrolyte injection, ensuring each cell receives the exact required amount for optimal operation and longevity.

Beyond these key areas, pumps are also utilized in other crucial battery manufacturing steps, including the precise dosing of performance-enhancing additives and even in acid recovery and recycling processes for a more sustainable approach. The selection of chemically compatible and highly accurate pumps, coupled with proper maintenance, is paramount for consistent battery quality and operational efficiency.

Meet Us at The Battery Show in Detroit!

Fluid Metering understands the critical importance of precision dosing and chemical control in battery manufacturing. We are excited to announce that our team will be attending The Battery Show in the automotive capital of the United States, Detroit, Michigan.

We look forward to connecting with industry leaders and showcasing our advanced fluid metering solutions. Representing Fluid Metering will be:

Thomas Breitenstein, Technical Sales Engineer

Kyle Burrows, Business Development Manager

Luis Cajas, Customer Relationships Manager

Come visit us at booth #2631 to discuss your specific battery manufacturing challenges and discover how Fluid Metering pumps can optimize your processes. We are eager to explore opportunities for collaboration and innovation in the rapidly evolving battery industry. We can't wait to see you in Detroit!

1 min read

Key Takeaways: For PCR and ddPCR pump selection, Fluid Metering’s FENYX™ Variable Dispense Pump offers precise flow control, low pulsation, and...

1 min read

Key Takeaways: Atomization transforms liquids into fine droplets for enhanced surface area, enabling precise sterilization, coating, and...

1 min read

Key Takeaways: Fluid Metering’s high-speed, high-pressure pump solutions—including the QD, QBLDC, and STF series—are designed to handle...