How Does Viscosity Impact the Accuracy of Pumps?

Key Takeaways: Fluid Metering’s viscosity-tolerant precision pumps maintain accuracy across a wide range of fluid viscosities by optimizing tubing...

In order for a pump to perform for a long period of time, it needs to maintain a high level of accuracy. If a pump's accuracy and repeatability changes over time, it will decrease the overall performance of the pump, and can possibly even render the pump useless. How can a user maintain accuracy and ensure that pumps remain reliable and repeatable over time? Here's a closer look at what you need to know:

The bottom line - pumps need to be precise, accurate, and provide long-repeatability because they are inherent functional requirements for proper fluid control measures. While accuracy is important in all pump applications, it's a crucial factor in the medical industry. Even the slightest deviation in accuracy could affect clinical decision making and diagnosis based on the test results obtained from medical diagnostic instrumentation and the reliability of the fluid control component integrated into the system.

The same is true of industrial applications. Some users only need to add a certain amount of fluid to a mixture. Add too much or too little, and the final product could be skewed and the end quality significantly altered. Accuracy, precision and repeatability are crucial when it comes to pumps and streamlining efficiency and effectiveness.

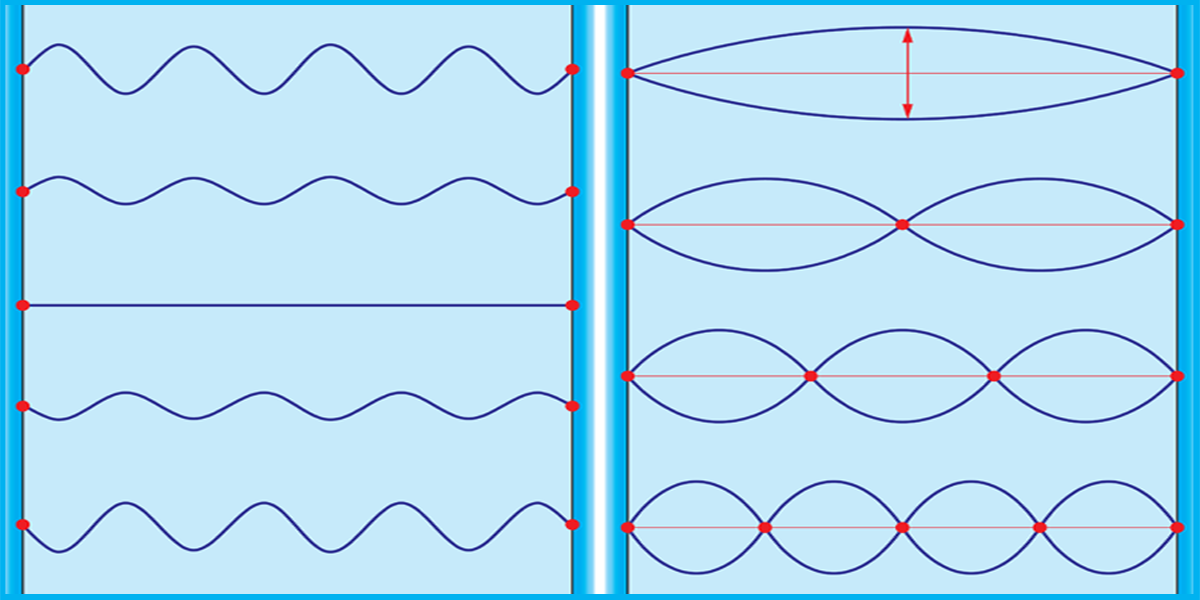

Calibration is important for ensuring pump accuracy - and there are a few key factors that play into calibration. One is the fluid type that the pump is processing, as understanding the likes of fluid density and viscosity are important for calibration.

At Fluid Metering, we work with customers to fine-tune calibration in-house before shipping them the pump. This step eliminates calibration error from the equation so that end users can begin using the pump right out of the box. Though there are some exceptions, once the pump is calibrated correctly, it maintains drift free accuracy, precision, and repeatability.

Over time, calibration may need to be adjusted based on the type of pump that is being used. For instance, a diaphragm or syringe pump may not maintain accuracy as well as other types of pumps.

Here's a look at some of the key factors that impact pump accuracy:

As mentioned above, there are many factors that can impact the accuracy of a pump. However, if users require a pump to be extremely accurate, there are a few pumps the experts at Fluid Metering always recommend starting with. There are many variations of these models, so these pumps can be customized to meet a user's exact needs and calibrated in-house to ensure accuracy.

There are several ways to maintain pump accuracy. One of the easiest ways is by adjusting the type of motor used to work with the pump. Stepper motors, for instance, work with Fluid Metering pump heads and have a high level of repeatability and reliability. In other words, they can stop in the same spot over and over again, and tend to be much more reliable than a DC or other type of motor.

Another thing to look out for is damage to the pump. Lip seals are a common area of wear and tear on pumps, but the good news is that they can be easily replaced. If an end user is working with a pre-calibrated pump and damaged lip seals are replaced, the pump should go back to its original calibration without issue. In other instances, the pump body or pump head may need to be replaced.

It's also worth mentioning again that it's imperative to understand fluid being used with the pump. If the fluid changes, the calibration is likely to change as well. And some fluids require more pump maintenance than others. For instance, if you're working with a crystal-forming fluid, the system is going to need to be flushed to prevent buildup and damage to the pump.

What are some common causes of your pump being out of calibration?

From wear and tear on the pump or pump components to changes in the fluid being processed to the type of motor that is powering the pump, there are various reasons why a pump's calibration may be altered.

High viscosity, dense or crystal-forming fluids can create problems with maintaining pump accuracy and repeatability over time.

If air bubbles enter the pump and play a role in the process, it can impact pump calibration.

Key Takeaways: Fluid Metering’s viscosity-tolerant precision pumps maintain accuracy across a wide range of fluid viscosities by optimizing tubing...

Key Takeaways: In microfluidic pump systems, pulsation refers to periodic flow rate fluctuations that can impact accuracy, stability, and...

Key Takeaways: Tubing and port size directly affect flow rate, pressure stability, and dosing accuracy, making them critical for precision fluidic...