Variable Dispense vs. Air over Liquid Dispense

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for ISO:13485 medical devices simplify fluidic architecture by combining priming,...

2 min read

Stephanie Moreau : Updated on July 22, 2025

Discarding the first few drops when dispensing liquids is a practice grounded in achieving precision and accuracy. However, when working with expensive reagents, having to discard any amount of fluid can be very costly. One common question that arises is whether the system user really needs to dispose of the first few drops to ensure the accuracy of the dispense volume. Let's delve into the reasons behind this practice and whether it is truly necessary.

Understanding Dispensing Mechanisms

Dispensing systems, whether manual pipettes, automated dispensers, or syringes, operate on principles that can introduce slight inconsistencies, particularly at the start of a dispensing session. These inconsistencies can stem from various factors:

Air Bubbles: During the initial setup or when a new tip or syringe is used, air bubbles can be trapped in the dispensing system. These bubbles can cause the first few drops to be inaccurate in volume.

Surface Tension and Capillary Action: The surface tension of the liquid and capillary action within the dispensing tip can cause variability in the first few drops. The initial interaction between the liquid and the dispensing tip can lead to drops that are not representative of the desired volume.

Temperature and Viscosity: The temperature of the liquid and its viscosity can affect the flow rate. At the start, the liquid may not be flowing at a consistent rate, leading to potential inaccuracies.

Residual Liquids: Any residual liquid from previous dispensing sessions can mix with the new liquid, altering the volume and concentration of the first few drops.

Practical Considerations

In practice, many professionals in scientific and industrial fields do discard the first few drops when precision is critical. Here are the reasons why this practice is recommended:

Ensuring Consistency: By discarding the initial drops, you allow the system to reach a stable state where the flow rate and volume become consistent. This helps in achieving more accurate and repeatable results.

Eliminating Air Bubbles: The initial drops can help to expel any trapped air bubbles in the dispensing tip, ensuring that subsequent dispenses are purely liquid, leading to more accurate volumes.

Maintaining Purity: Disposing of the first drops helps in maintaining the purity of the dispensed liquid. This is especially important in chemical and biological experiments where contamination can lead to erroneous results.

When Is It Necessary?

When It Might Be Less Critical

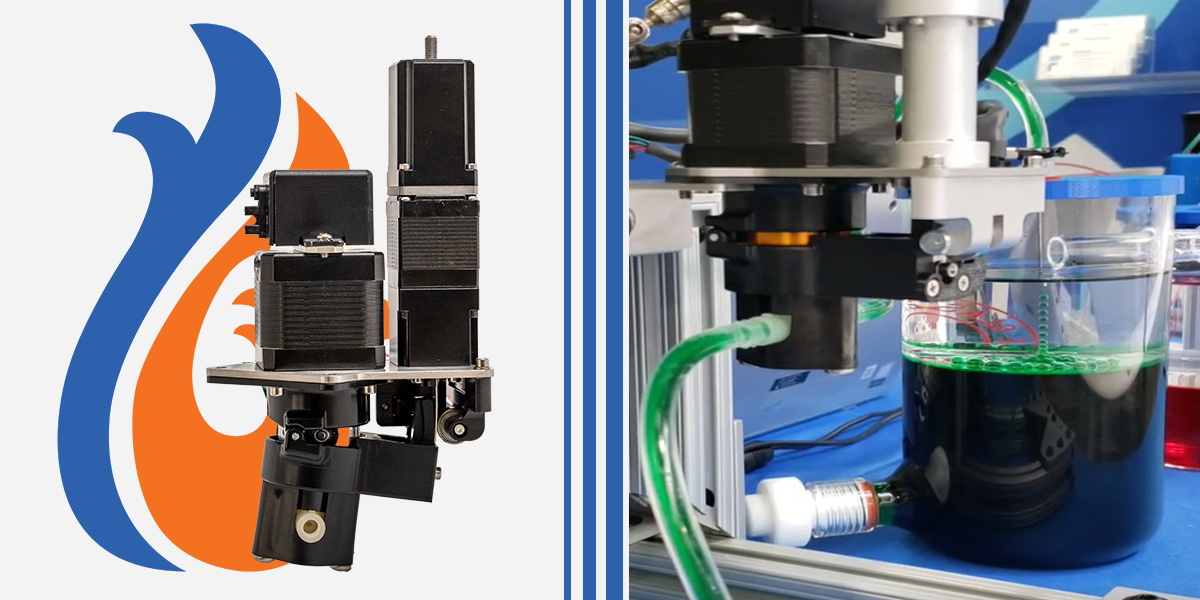

How Fluid Metering Pumps Resolve This Concern

Fluid Metering pumps offer a significant advantage in liquid dispensing by providing consistent and accurate volumes from the very first drop. These pumps are designed to minimize the common issues such as air bubbles, surface tension, and residual liquids that typically necessitate the discarding of initial drops. By maintaining a precise and steady flow, Fluid Metering pumps ensure that the volume dispensed is accurate from the start, eliminating the need for the extra step of discarding the first few drops. This makes them an excellent choice for high-precision applications where every drop counts. With Fluid Metering pumps, you can trust that your measurements will be reliable and consistent, enhancing the efficiency and accuracy of your work.

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for ISO:13485 medical devices simplify fluidic architecture by combining priming,...

Key Takeaways: Non-contact dispensing for diagnostics and IVD reduces contamination risk, eliminates disposable tip waste, and supports ESG goals by...

Key Takeaways: For monomer dispensing in contact lens manufacturing, Fluid Metering’s valveless piston pumps deliver ±0.5% accuracy and consistent...