A Guide to Low-Maintenance Microfluidic Pumps

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

3 min read

Thomas Breitenstein : 3/12/24 7:53 AM

In the dynamic field of healthcare, microfluidics has emerged as a revolutionary force, shaping the next generation of medical devices. Among the key innovations driving this transformation are microfluidic pumps: compact marvels that add precision and control to the manipulation of fluids on a microscale. Let’s explore some of the fascinating ways microfluidic pumps are propelling healthcare into a new era of efficiency and customization.

1. Precision Diagnostics Amplified

Microfluidic pumps play a crucial role in enhancing precision diagnostics by enabling controlled fluid movement within microchannels, especially for applications that require precise concentrations and flowrates. While traditional diagnostic methods often involve manual sample handling and lengthy processing times, microfluidic pumps allow manufacturers to automate these processes, ensuring quick, consistent, and reproducible results. This level of control accelerates diagnostic procedures and minimizes the risk of errors, providing healthcare professionals with reliable data for accurate and timely decision-making.

2. Connectivity with Lab-on-a-Chip Devices

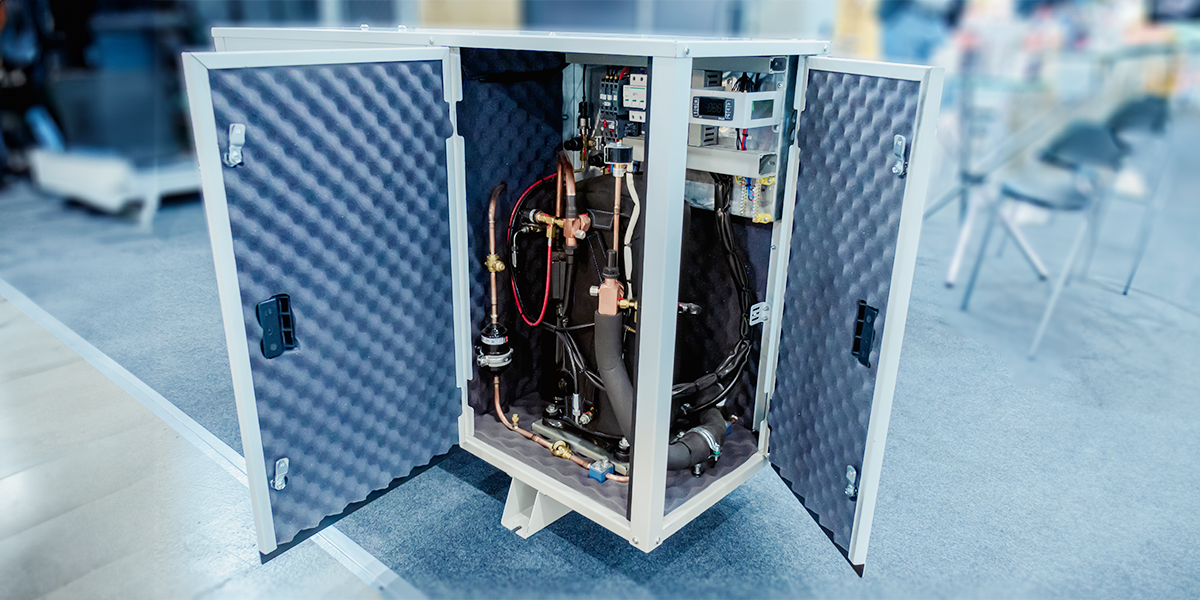

The integration of precision microfluidic pumps with LOC (lab-on-a-chip) devices represents a significant leap forward in healthcare technology. LOC devices can carry out intricate tasks such as sample mixing, fluid propulsion, and controlled reactions. Integrating microfluidic pumps with these chips enhances the versatility and complexity of LOC platforms, offering the potential for more sophisticated analyses in a compact and portable format.

3. Point-of-Care Precision Pumping

Microfluidic pumps are at the forefront of the shift towards point-of-care testing, where rapid and accurate diagnostics are essential. These compact pumps provide precise fluid control in portable devices, allowing for real-time analyses at the patient's bedside. Whether you’re measuring biomarkers or detecting infectious agents, the integration of microfluidic pumps in point-of-care instruments ensures a level of precision that’s indispensable in critical medical scenarios. Many of these pumps are even equipped with sensors and wireless communication capabilities to enable remote monitoring and data collection for telemedicine applications.

4. Pumping Life into Personalized Medicine

Microfluidic pumps are actively advancing the field of personalized medicine. Integrating these pumps into medical devices facilitates the manipulation of small fluid volumes required to analyze individual patient health parameters and allows for accurate regulation of flow rates and dosages in targeted therapeutic approaches like drug administration. As a result, healthcare professionals can tailor treatment plans based on genetic information, biomarkers, and real-time monitoring. Implantable or wearable devices with microfluidic pumps can provide continuous and adjustable drug delivery, responding in real-time to changes in a patient's physical or physiological state. Despite their small sizes, microfluidic pumps can also be designed for parallel processing, enabling high-throughput screening and analysis, which is essential for drug discovery and development.

5. Cost Saving Materials & Customization

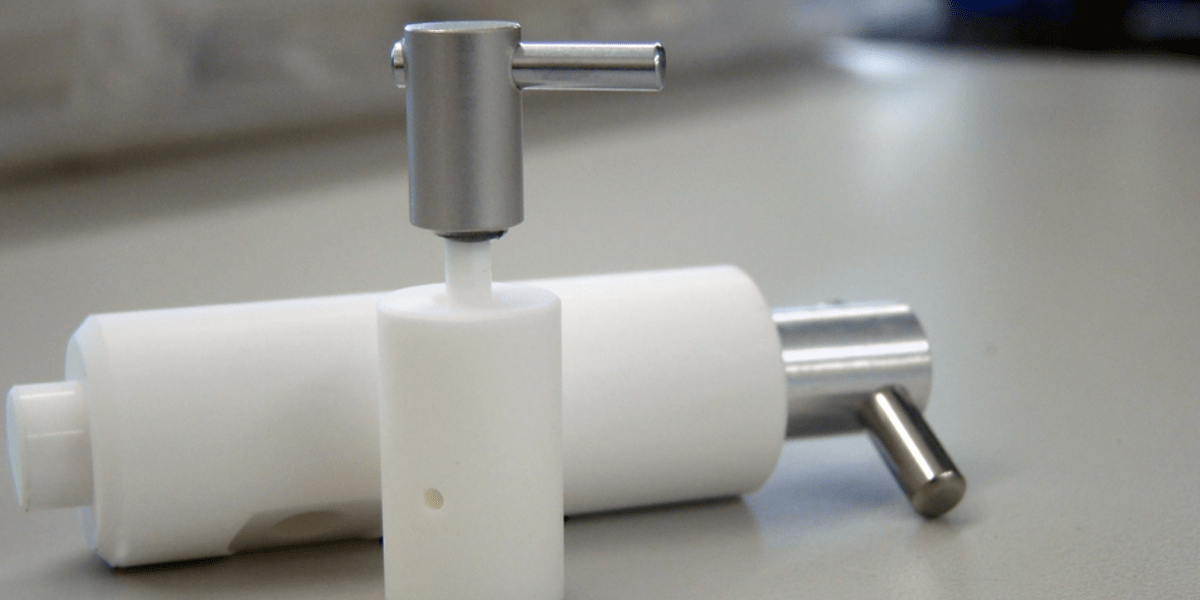

Designing, manufacturing, and performing diagnostic tests is expensive which usually leads to higher patient costs. The use of precision microfluidic pumps in these devices can help with cost savings, making tests more affordable for patients. Fluid Metering's FENYX® Variable Dispense pump helps simplify fluidic architecture by eliminating the need for separate priming and flushing pumps and minimizing the amount of fluidic connections in each device, allowing for a higher level of reliability and cost savings. Typically, the most expensive part of running any diagnostic test is reagent consumption. By using a high precision dispensing pump capable of delivering small volumes (down to nanoliters), reagent use can be cut back making tests more affordable.

As the medical industry advances and upscales mass production of OEM machines and at-home test kits, factors like quality, integration, convenience, and cost effectiveness are becoming more important now than ever. At Fluid Metering, we hold all our suppliers to high standards and have a stringent quality control process to ensure product reliability. Our thorough final inspection process catches any faults in production and helps your OEM devices pass the FDA 510(k) Clearance Process with ease. As we continue to innovate and push the boundaries of the microfluidic field alongside our customers, we look forward to opening the doors to new possibilities and improvements in healthcare. Contact us today to join the next-gen medical revolution!

Key Takeaways: Fluid Metering’s low-maintenance microfluidic pumps for lab automation deliver long-term precision with minimal wear, thanks to a...

1 min read

Key Takeaways: In microfluidics for food safety and quality control, Fluid Metering pumps enable precise delivery of reagents for pathogen...

1 min read

Key Takeaways: In low-noise microfluidic pump applications, such as home dialysis or dental devices, reducing vibration and acoustic output is...