1 min read

A Slurry of Advanced Techniques for Pumping Micro Silica Beads

Key Takeaways: Fluid Metering’s precision pumps for silica bead slurries handle particle sizes from 3µm to 800µm with low shear, no entrapment, and...

Fluids with low viscosity tend to have low resistance. They shear easily and their molecules flow quickly, which can make them easy to pump and process.

High viscosity fluids, on the other hand, are the opposite. They move slowly and don't deform easily. Some even tend to behave more like solids than liquids, which can become a problem for pumping.

But while high viscosity fluids certainly have their challenges, it is possible to pump them - you just need the right pump assembly, and you may need to give them a little bit of extra help. In this post, we'll discuss some of the guidelines and tips to successfully pump these high viscosity fluids, from selecting the right initial pump from the start to special pump heads that can help get the job done. Here's a closer look at what you need to know about pumping high viscosity fluids:

The million-dollar question: Is it possible to pump high viscosity fluids?

The answer: Yes!

But it's worth noting that it can be difficult for many customers to properly pump such fluids - and a common limitation is the pump technology that is being utilized. Specifically, pumping has a lot to do with flow rate. For instance, if you're aiming for a flow rate of 1000 milliliters per minute, you may not have great success when working with high viscosity fluids. This is largely because high viscosity fluids don't move all that easily - and for a pump to process fluid, it needs to move through the tubing and to the pump.

Success has a lot to do with the pump that you purchase. In the next section, we'll get into some of the things to look for in a pump that's intended to process high viscosity fluids.

Here are some things to look for in a pump needed to process high viscosity fluids:

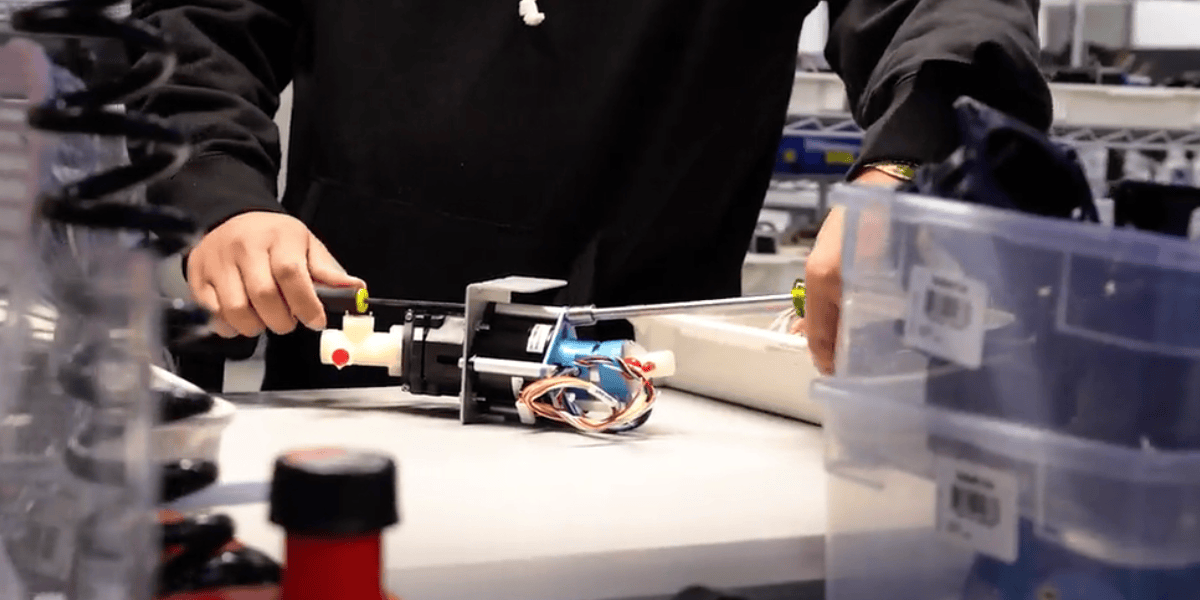

Additionally, many of Fluid Metering’s pumps are offered with a special pump head intended specifically for those who are intending to process high viscosity fluids. This head consists of a cylinder casing and includes options to keep the fluid warm within the pump head. As we noted earlier, warming the fluid can help it move easily throughout the assembly, and lead to a greater likelihood of success when trying to pump high viscosity fluids.

Now that we've covered some of the "do's," let's look at some of the things that you should not do if you're hoping to have success pumping high viscosity fluids. As you might expect, most of the “don’ts” here are just the opposite of the "do's" that we listed above. They include things like pumping high viscosity fluid through pumps with small tubing, pumping at high RPMs and failing to use any sort of pressure feed or heating. Doing this can all put strain on the pump and lead to unsuccessful outcomes.

As you can tell from reading this post, pumps are very application specific. That's why we advise that you always contact an expert if you need help pairing a pump with a specific application, like processing high viscosity fluid. At Fluid Metering, Inc., we have a variety of pumps for a variety of applications - and we can help you find the right one for yours. With years of experience and high-quality pumps that can exceed your application expectations, our experts are standing by and ready to help you.

For more information on how to successfully pump high viscosity fluids and to browse our line of pumps that can do it, contact Fluid Metering today. Remember, selecting the right pump is something that tends to be very application specific. Work with Fluid Metering today so you can have peace of mind that you're choosing the right one for your application.

1 min read

Key Takeaways: Fluid Metering’s precision pumps for silica bead slurries handle particle sizes from 3µm to 800µm with low shear, no entrapment, and...

Key Takeaways: Fluid Metering’s viscosity-tolerant precision pumps maintain accuracy across a wide range of fluid viscosities by optimizing tubing...

1 min read

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...