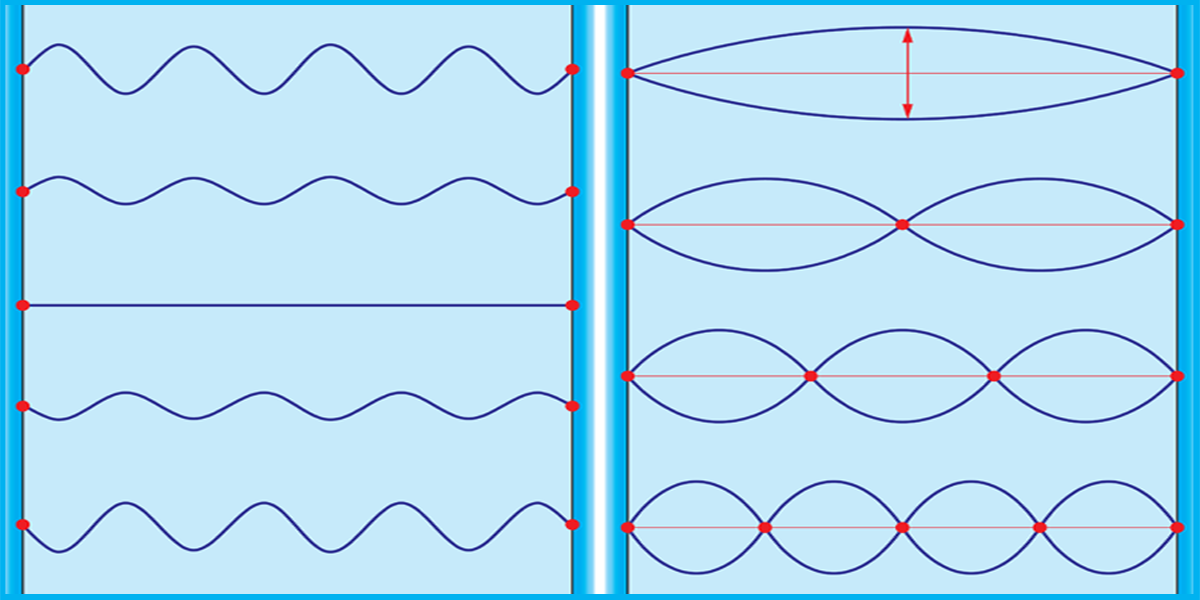

What is Pulsation?

Key Takeaways: In microfluidic pump systems, pulsation refers to periodic flow rate fluctuations that can impact accuracy, stability, and...

Ever since the 18th century, manifolds have been utilized in engineering innovations from the steam engine to plumbing, refrigeration, and more. Today, manifolds serve as crucial components in many microfluidic systems, adding to both functionality and efficiency in a wide variety of applications. So, what exactly is a manifold, why is it so important, and how can you integrate one into a microfluidic system?

Key Benefits of Using Manifolds

Using manifolds in microfluidic systems offers several key benefits including:

Impact of Manifold Design

The design of a manifold can significantly impact fluid flow and overall system performance. Manifolds can be used solely for routing liquid/gas or they can also contain other components with additional functionalities. Microfluidic manifolds are typically custom-designed to meet specific application needs and can include components such as pumps, valves, filters, regulators, and sensors.

Customized manifold designs include:

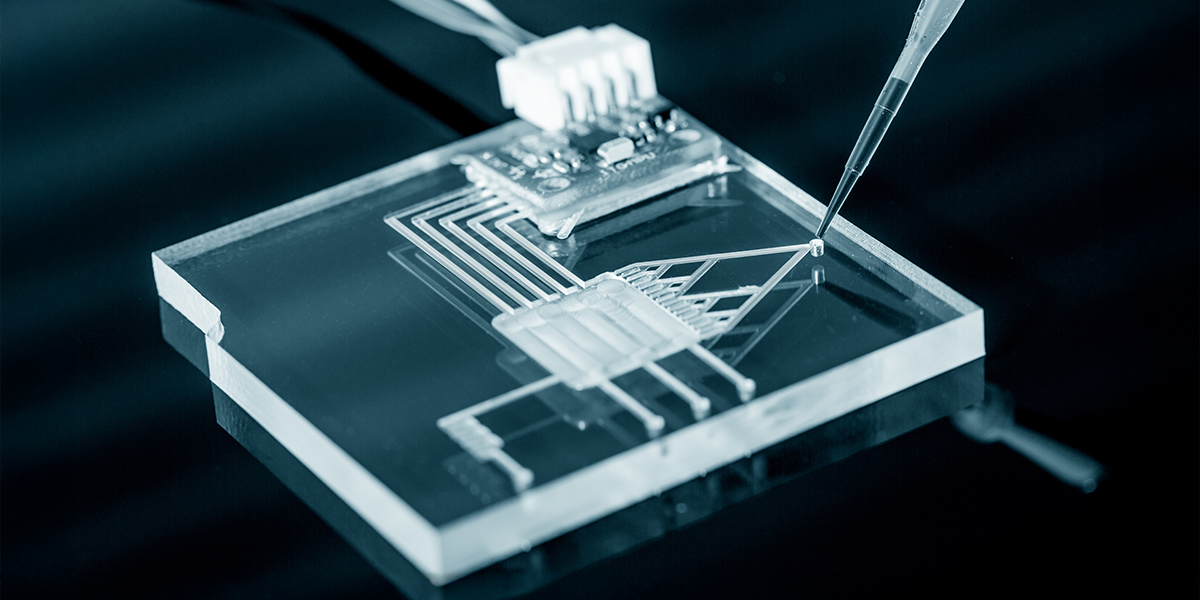

Integrating Microfluidic Pumps with Manifolds

The biggest challenge in using manifolds within microfluidic systems is ensuring the compatibility of pumps with manifold designs. For instance, Fluid Metering’s TRYTON™ Pulseless Nanoliter pump is designed to easily adapt to any manifold, ensuring seamless integration. While some pumps or fluidic systems can be easily modified to fit a specific manifold, like the rest of Fluid Metering’s OEM and laboratory pumps, others are not as versatile and require the pump itself to be designed according to the manifold’s specifications.

Real-World Applications

The use of manifolds can vary based on system architecture preferences. Some OEMs prefer routing everything through a manifold for a refined design. However, this can make troubleshooting field issues more challenging, as it can be difficult to identify which part is causing a problem. Additionally, the more complex a manifold is, the more it can add to the overall cost of the system.

Nevertheless, manifolds play vital roles in microfluidic systems by simplifying connections, reducing leak points, and minimizing maintenance. Their design is crucial for optimal performance and to meet specific needs. Despite some challenges, their benefits make them indispensable across an endless field of microfluidic applications.

Need help integrating a manifold into your fluidic system? Our team of experienced engineers is ready to dissolve your challenges and manifold your success with practical, streamlined solutions!

Key Takeaways: In microfluidic pump systems, pulsation refers to periodic flow rate fluctuations that can impact accuracy, stability, and...

1 min read

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for OEM applications offers programmable dispense volumes (2–400 µL), self-priming,...

Key Takeaways / Highlights Piston pumps(rotating and reciprocating) offer unmatched precision, chemical resistance, and longevity—ideal for...