Fluid Metering’s TRYTON™ Pulseless Nanoliter Pump

Key Takeaways:

2 min read

Nicolas Mercier : Updated on January 22, 2026

What is an In-Line Pump?

Unlike rotating, reciprocating pumps where the piston spins while pushing in and out, in-line pumps keep everything moving within a line. In an in-line pump, the piston moves along the same axis as the linear actuator (motor that moves forward and back), creating controlled flow with minimal pulsation - a major advantage over other pump mechanisms.

TRYTON vs. Standard In-Line Pumps

Precision & Accuracy

When measuring fluids on the microscale, each small droplet has a huge impact, so every measurement must be as exact as possible. The TRYTON pump boasts an incredible accuracy of ±2% at 1 microliter, equating to ±20 nanoliters. This translates to ±<0.02% full stroke, reducing errors, ensuring consistency, and exceeding far beyond the competition.

Eliminating Backlash

A common issue with standard in-line pumps is backlash, which effects every first dispense. This forces customers to rely on software compensation to correct inconsistencies. Fluid Metering’s TRYTON pump eliminates this problem entirely, maintaining accuracy and repeatability without the need for software compensation. Users benefit from TRYTON's anti-backlash mechanism and are given full confidence in every drop, regardless of the first or last dispense.

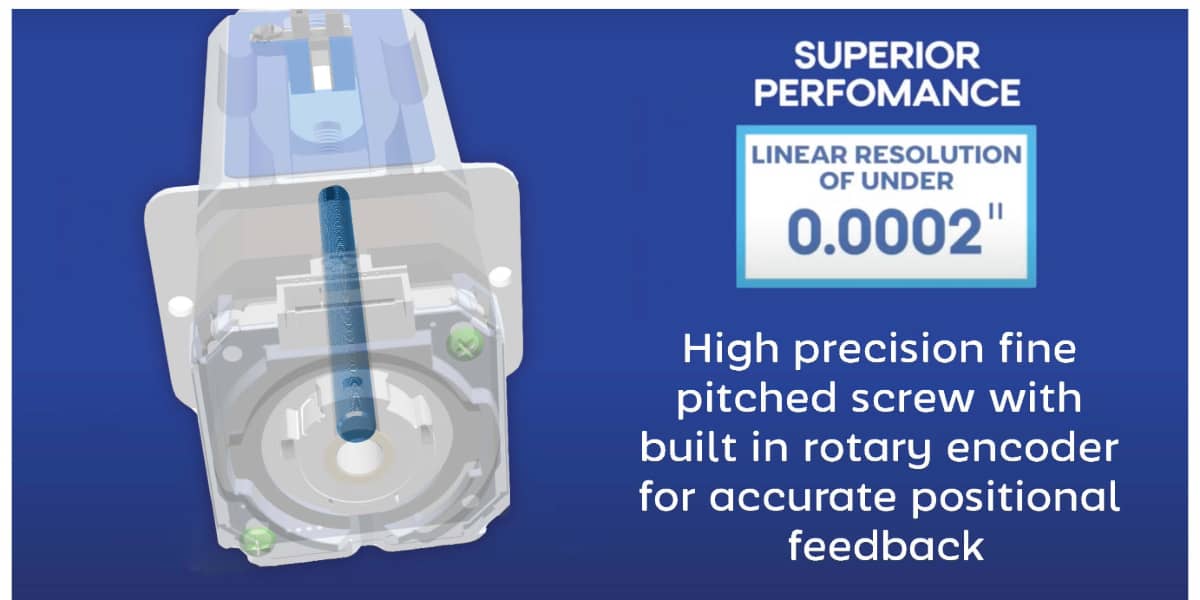

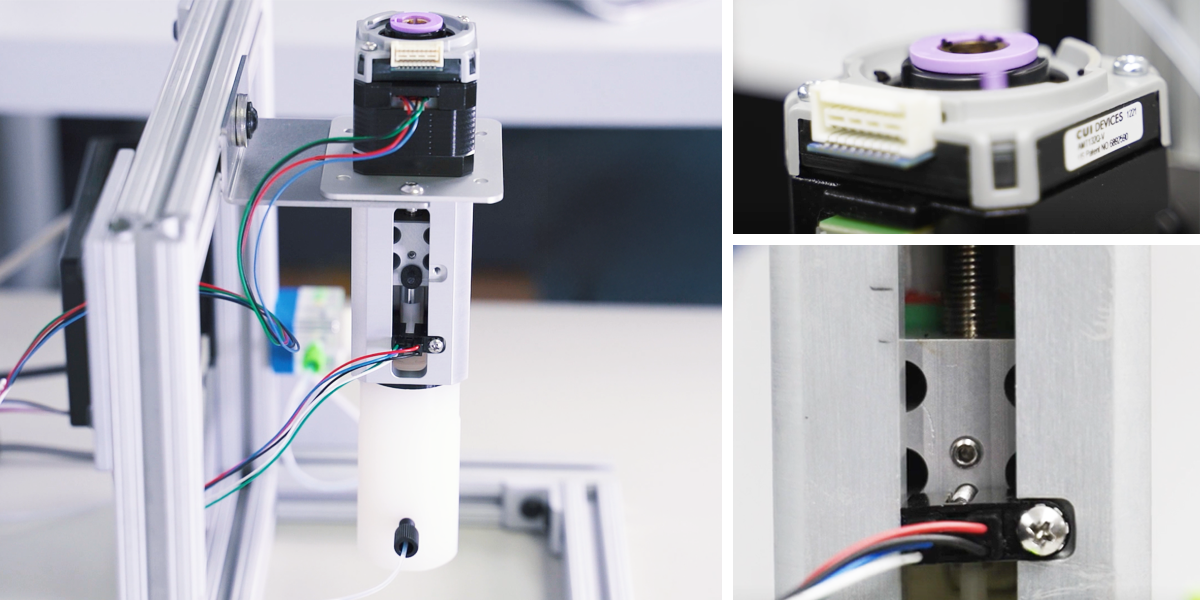

Advanced Feedback System

The TRYTON’s rotary encoder offers a resolution of 0.02 degrees, allowing for accurate positional feedback at all times. Competitor pumps struggle to reach this level of performance, making the TRYTON the superior choice for applications requiring extreme accuracy.

Optimized Flow Rate & Dispense Volume

With an accuracy of 2% at 1 microliter, a resolution of 31 nanoliters per step, and a full stroke volume of 150 microliters, the TRYTON provides precise, repeatable dispensing with impeccable control - a clear advantage over competitor pumps.

Chemical Compatibility & Durability

Fluid Metering offers a wide range of materials to meet the chemical requirements of any application. The TRYTON pump's internals are customized and tested for each customer's individual application to ensure complete chemical compatibility with all fluid-handling needs.

Lower Costs & Engineer-to-Engineer Support

Where standard in-line pumps often require costly maintenance servicing and frequent recalibration, the TRYTON pump requires virtually since it is designed to last the lifetime of the instrument*. With its incredible precision retention of less than 1% degradation over time, the TRYTON delivers long-term performance without the cost and hassle of regular upkeep, saving customers time and money. Plus, Fluid Metering’s expert engineer-to-engineer support ensures that every client receives specialized guidance for optimal performance.

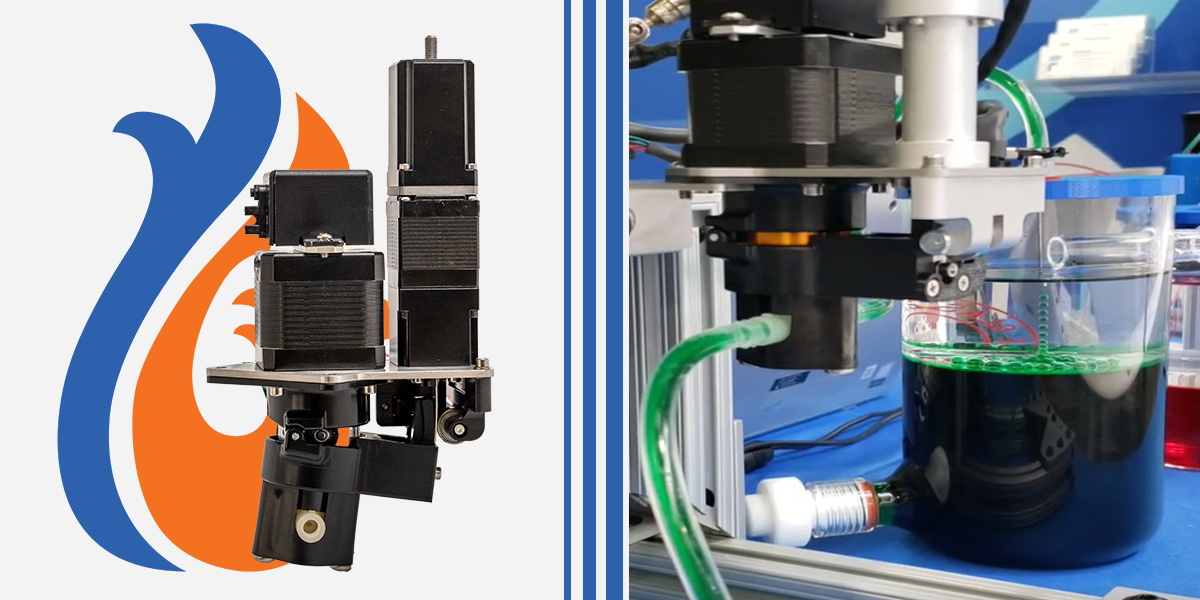

Ride the Engineering Wave to Superior Fluidic Control

When accuracy, durability, and efficiency are at the top of your priority list, Fluid Metering’s TRYTON Pulseless Nanoliter pump stands in a league of its own. By eliminating backlash, offering superior precision, and reducing long-term maintenance costs, it surpasses competitor in-line pumps in every key area. Whether you’re looking for better chemical compatibility, improved dispense accuracy, or unbeatable reliability, the TRYTON is the future of precision fluid handling.

Looking to blow your competition out of the water? Contact Fluid Metering today and discover how the TRYTON pump can enhance your operations!

*Please contact our technical sales team on understanding your unique requirements.

Read More

Read More

Key Takeaways: The TRYTON™ Pulseless Nanoliter Development Kit offers OEMs a plug-and-play solution for ultra-precise fluid control, delivering ±2%...

Key Takeaways: Non-contact dispensing for diagnostics and IVD reduces contamination risk, eliminates disposable tip waste, and supports ESG goals by...