Fluid Metering’s TRYTON™ Pulseless Nanoliter Pump

Key Takeaways:

2 min read

Nicholas Mercier & Colin Rademacher : Updated on July 22, 2025

Searching for a quick, seamless, all-in-one solution for superior fluid control? Look no further than the TRYTON™ Pulseless Nanoliter Development Kit! With its comprehensive package, advanced features, and exceptional performance, the TRYTON Development Kit is the ideal choice for life science OEMs seeking reliability and efficiency in fluid dispensing.

Why Choose the Development Kit?

The TRYTON Development Kit brings you a ready-to-go advantage for rapid deployment, saving you tons of valuable time and effort. It includes all the necessary components you need to set up your TRYTON within a completed system, guaranteeing you can begin operation and testing straight away! Inside the case, you’ll find:

(1) TRYTON Pulseless Nanoliter Pump

(1) Controller Box

(1) Power Supply + Line Cord

(1) RS232 to USB Connection Cable

(1) Motor Extension Cable

(1) Sensor Extension Cable

(2) Tubing (FEP, 1/16” ID x 1/8” OD)

(8) Tubing Ferrule (Yellow)

(8) Tubing Ferrule Nut (Green)

(1) Luer Adapter

(2) Dispense Tips (1 Blue, 1 Red Smooth Flow Tapered Tip)

(2) Solenoid Valve

(2) Power Switch

(2) Female Barrel Jack to Screw Terminal

(1) 1-to-4-way Power Splitter Cable

Advanced Control

The TRYTON Development Kit offers a complete hardware and software package. Advanced firmware comes pre-loaded onto the driver board and is easily controlled via the FMI Configuration tool. Stay ahead with the latest advancements! Download the newest version for free from the Fluid Metering website and keep your system up-to-date.

Superior Performance & Compatibility

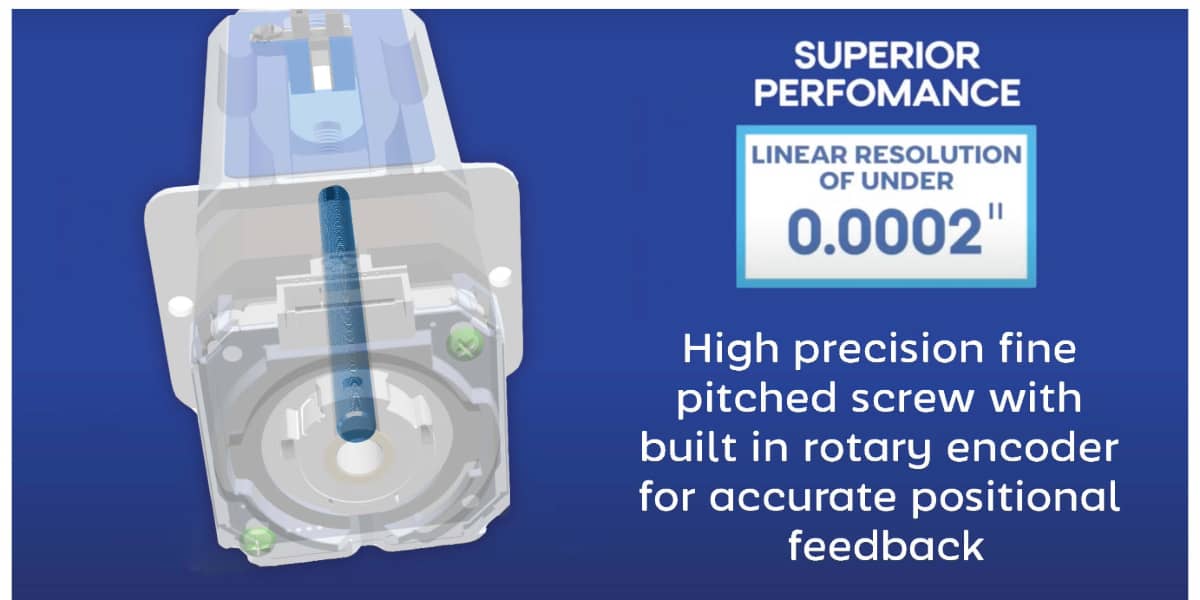

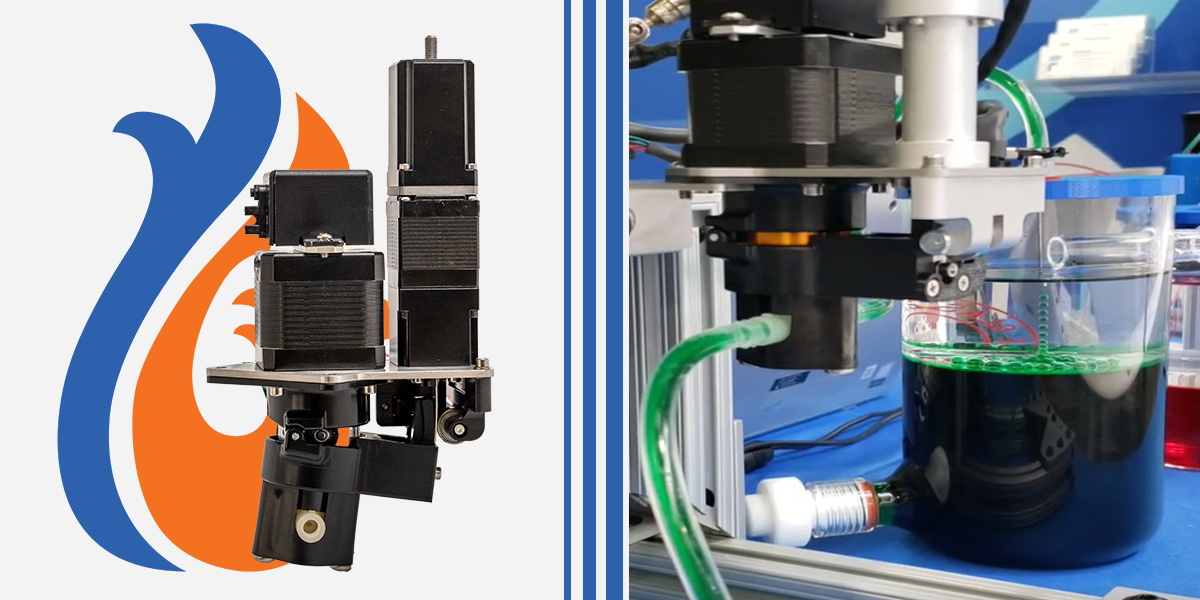

The TRYTON Pulseless Nanoliter pump flaunts incredible precision and accuracy down to 1μL with less than ±2% variance while maintaining a large, full-stroke dispense volume of 150μL. Its patent-pending drive mechanism ensures zero backlash, reducing the waste of expensive resources like assays and reagents.

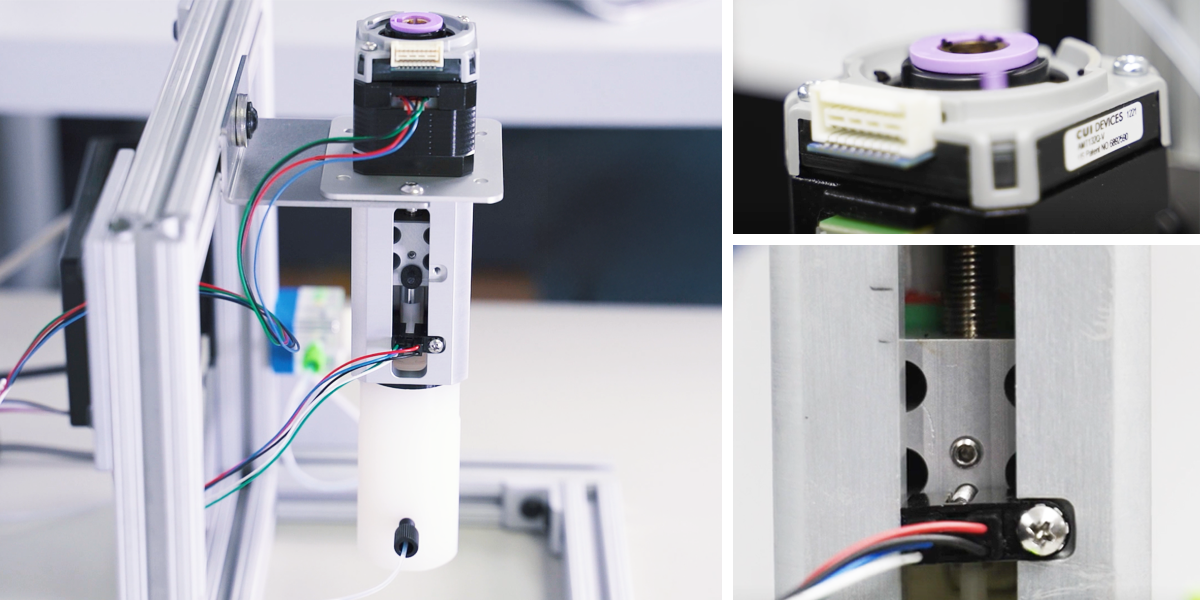

The TRYTON’s durable, compact construction features a Zirconia piston and FKM/UHMW-PE seals, each capable of handling some of the most aggressive chemicals. An advanced feedback system, equipped with a rotary encoder that provides over 4,000 pulses per revolution, delivers accurate positional feedback with ultra-fine 0.02° resolution. In addition, it has a high-precision, fine pitch lead screw and dispense resolution of 0.031μL per full step.

Ready to bring invaluable accuracy and efficiency to your project? Contact us today to ride the microfluidic wave to success!

Read More

Read More

Key Takeaways: Non-contact dispensing for diagnostics and IVD reduces contamination risk, eliminates disposable tip waste, and supports ESG goals by...

Key Takeaways: The TRYTON™ pump delivers ±2% accuracy at 1 µL with no backlash, outperforming standard in-line pumps in precision, repeatability,...