1 min read

Fluid Metering Sits Down with John Morris Group to Discuss Innovations in Dispense Pump Technology

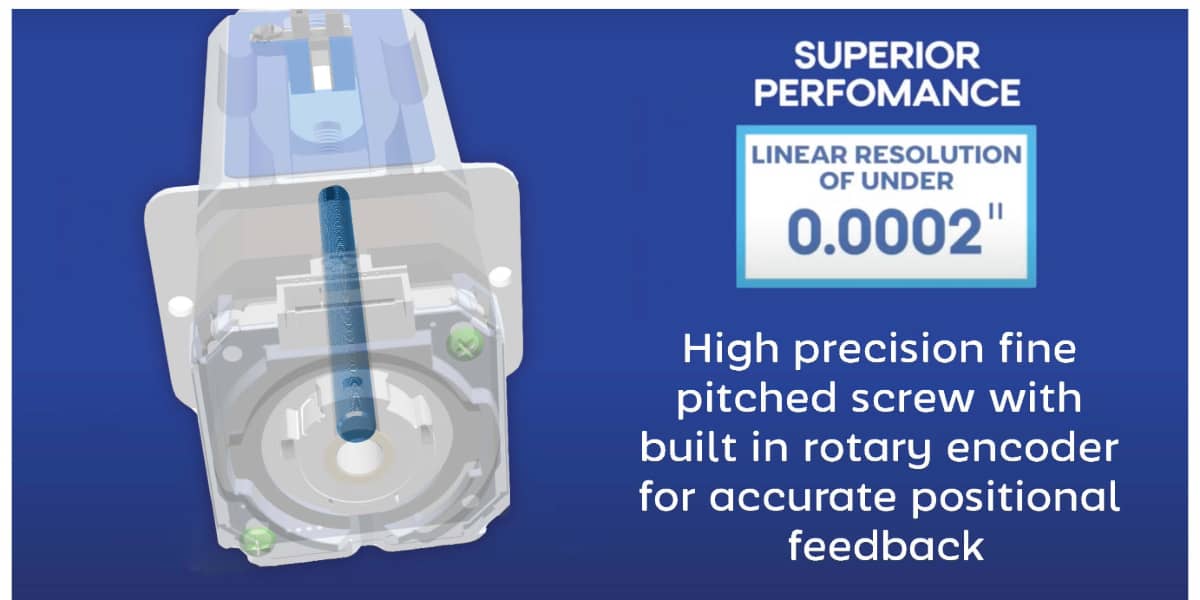

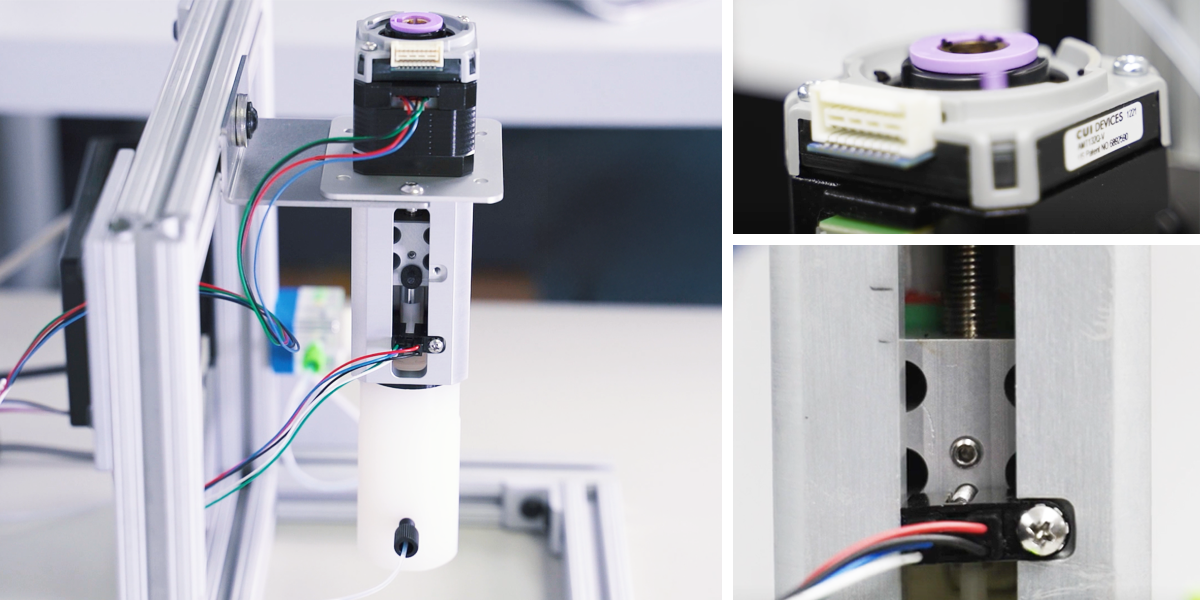

Key Takeaways: Fluid Metering’s FENYX® variable dispense pump for OEM applications offers programmable dispense volumes (2–400 µL), self-priming,...