1 min read

The Advantages of Fluid Metering Piston Pumps Over Peristaltic Pumps

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

3 min read

Dickson Ong : Updated on July 22, 2025

Can pumps integrate into OEM systems?

It's a question that we often receive, as end users want to customize the pump as much as possible so that it works better for them. And while this can be done, there are many considerations that need to be weighed before it's carried out. In this post, we'll cover how pumps integrate into OEM systems, how to know what pumps to integrate, and more.

The short answer: yes.

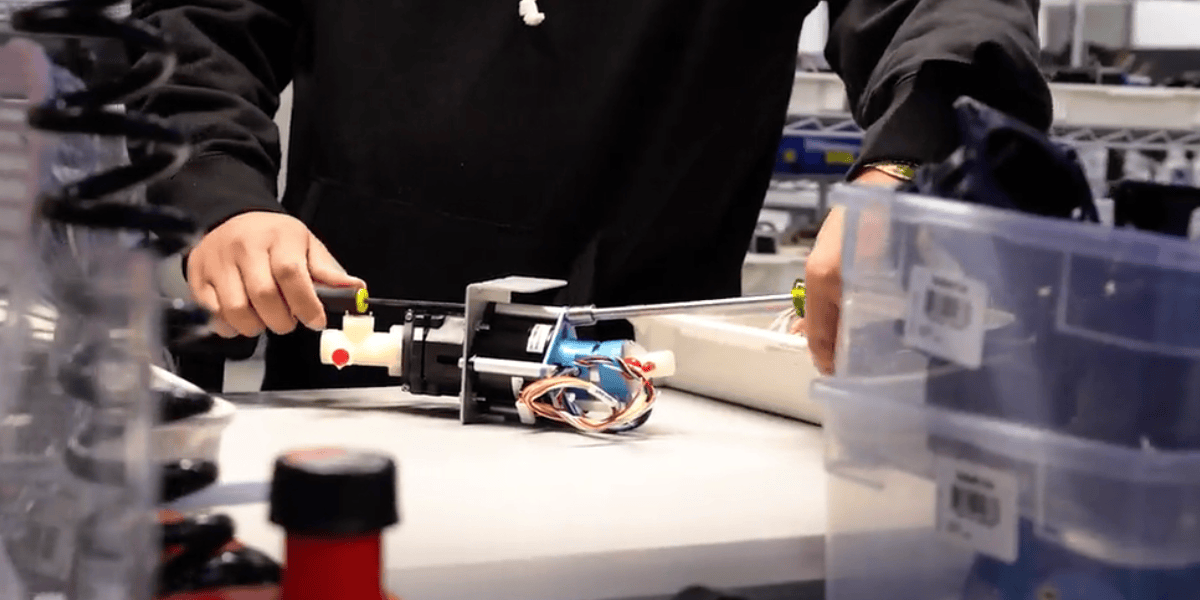

Pumps are typically configured by selecting a motor drive and a pump head. This is done to ensure that the pump assembly is capable of providing the correct flow and dispense volume. However, the pump is only one piece of the puzzle as most OEM systems will require some type of stepper controller.

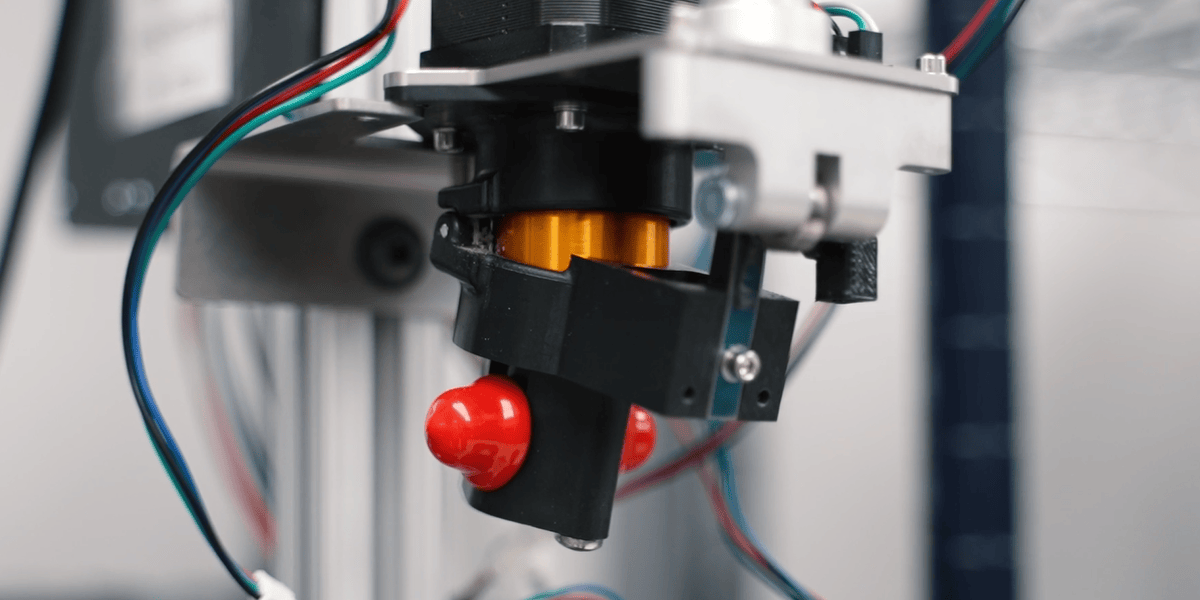

Fluid Metering offers what we call the ICST-02 as a controller option; however, customers are not limited to what we offer. Many applications will utilize some of the vast options available on the market for off the shelf controllers. Other applications will develop their own controllers to better fit their application.

Pumps are typically sold as a mechanical unit and can be configured with various motors and pump heads. These pump heads are driven by a stepper motor, which requires a separate controller to operate. The stepper motor helps to adjust speeds and can help with either increasing or decreasing flow rates, dispensing volume, and more. There are plenty of off the shelf stepper controller options that enable users to send live commands to the stepper motor/ pump to direct it on what to do.

End users can develop their own stepper motor controllers and there are applications where users purchase one off the shelf. Others utilize FMI stepper motor controller if it fits the application requirements.

Essentially, a pump is looking for stepper controller signals, and whatever controller a user decides to implement simply needs to be capable of working with a stepper motor.

In most cases, there are two types of motor drives that can be integrated into OEM systems. These drives require separate methods for integration. Here's a look at the two options:

Keep in mind that the controller you choose needs to have the ability to drive the stepper motor and the optical sensor. For DC motor drives, users need to have a voltage controller of some type to vary the voltage that is supplied to the motor to control speed and other variables.

Yes, this can most definitely be integrated into an OEM system or a large instrument. However, it may have some limiting factors depending on what your requirements are. If you're not looking to constantly change your parameters throughout the system, the ICT02 could be the ideal solution for you. You would need to pre-program the controller to the parameters that you plan to operate at, and that would trigger the function as needed throughout the system - regardless of what it's connected to.

In order to communicate with the ICST-02, the PLC would need to have RS485 communication capabilities. If your PLC has the ability to send communication over serial terminals, then you should be able to connect and integrate the controller into your PLC. Just make sure that you do your homework beforehand, so you have a better understanding of how it integrates.

FMI offers a wide range of pumps when it comes to flow rates, dispense volumes, flow characteristics, and other variables. The type of pump you choose to integrate really depends on what you're looking to achieve with your instrument. End users should be asking questions, such as:

By knowing this information, our experts at Fluid Metering are able to narrow down the pumps that would be applicable to your needs. We encourage you to reach out to one of our experts to determine the best fit for your application. There are many different combinations to navigate when it comes to pump availability, and it's always best to get some expert advice so you're not left guessing at what type of pump would work best.

Our experts are standing by and ready to help you with all your pump needs. Contact us today for more information.

1 min read

Key Takeaways: For precision piston pumps vs. peristaltic pumps, Fluid Metering’s valveless designs deliver superior accuracy, high-pressure...

1 min read

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...

Key Takeaways: In precision microfluidic dispensing systems, trapped air can cause wide variation in dispense volumes and compromise...