Why Tubing and Port Size Matter in OEM Pump Designs

Key Takeaways: Tubing and port size directly affect flow rate, pressure stability, and dosing accuracy, making them critical for precision fluidic...

1 min read

Blake Webb : September 25, 2025

Key Takeaways:

Traditional waste pumps in IVD systems are prone to clogging and failure, especially when handling viscous fluids, debris, or solids—posing serious reliability risks.

FMI’s valveless rotary reciprocating piston pumps offer a robust alternative, eliminating common failure points and ensuring consistent performance under vacuum and with challenging waste materials.

Peristaltic pumps suffer from tubing fatigue, leading to leaks and inconsistent flow, whereas FMI’s enclosed design minimizes maintenance and enhances long-term reliability.

In-vitro diagnostics (IVD) systems are designed with precision in mind—until it comes to waste. All too often, waste handling is an afterthought. But ignoring it can result in catastrophic failures: hazardous spills on the lab floor, internal machine contamination, or even cross-contamination between samples.

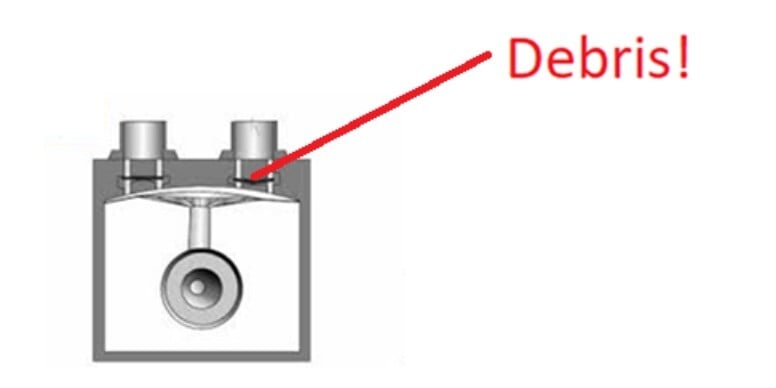

Above: Debris! Passive valves in diaphragm and bellows pumps are common clog points. Foreign material from pierced caps, coagulants, magnetic beads, or viscous reagents can quickly compromise pump performance.

The Problem with Traditional Waste Pumps

Many IVD systems rely on bellows or diaphragm pumps, which include passive flapper valves. These valves are prone to:

Waste isn’t clean. It contains viscous fluids, solids, and unpredictable residues—all of which are pump killers when you rely on valve-based designs.

Over-Complicated Architectures

A common setup includes:

This multi-pump design introduces complexity, cost, and failure points.

Why FMI pumps are ideal for IVD waste:

Don’t let waste be your system’s weakest link. Build it right, and you’ll avoid surprises when the stakes are high.

Tubing Wear in Peristaltic Pumps

Peristaltic pumps are another common choice in IVD systems, but they come with a hidden risk: tubing fatigue. Over time, the repetitive compression and relaxation of the tubing leads to material degradation. This can result in leaks, ruptures, or inconsistent flow—especially when handling aggressive or viscous waste fluids. In contrast, FMI pumps are fully enclosed systems with no wear components. This dramatically reduces maintenance needs and eliminates the risk of unexpected leakage or failure during critical operations.

Key Takeaways: Tubing and port size directly affect flow rate, pressure stability, and dosing accuracy, making them critical for precision fluidic...

1 min read

Key Takeaways: Clinical chemistry and immunoassay analyzers require microliter-level precision, fast fluid handling, and contamination...

1 min read

Key Takeaways: Biological samples can contaminate pump internals, reducing accuracy, causing biofouling, and requiring costly, time-consuming...