How Does Viscosity Impact the Accuracy of Pumps?

Key Takeaways: Fluid Metering’s viscosity-tolerant precision pumps maintain accuracy across a wide range of fluid viscosities by optimizing tubing...

3 min read

Blake Webb : February 17, 2026

%20(9).png)

If you're designing next-generation in vitro diagnostic (IVD) systems, you've likely noticed something: PFAS material considerations are no longer optional. Regulatory scrutiny is intensifying—particularly in the European Union—and medical device OEMs are being asked harder questions about the materials in their fluid-handling components.

For pump selection, this creates a challenge. How do you balance material compatibility, regulatory considerations, and long-term reliability without overhauling your entire system design?

Let's break down what matters when selecting pumps for PFAS-related applications.

Perfluoroalkyl and polyfluoroalkyl substances (PFAS) are chemically stable and persistent—which is precisely why they're now under regulatory review. In fluid-handling systems, this means taking a closer look at wetted materials: the components that directly contact your fluids.

Depending on your application, certain polymers, elastomers, or additives may need to be avoided or limited due to:

The goal isn't to eliminate all potential risk—it's to select materials with well-understood properties and a proven track record in precision fluid handling.

FMI's CeramPump® technology takes a different approach. Instead of relying on traditional elastomer-based pumping mechanisms, CeramPump® uses a wetted path primarily composed of ceramic components.

Why ceramic? Precision ceramics offer:

In PFAS-related applications where material inertness and long-term surface stability matter, ceramic provides a level of consistency that's hard to achieve with other materials.

Inside the CeramPump®

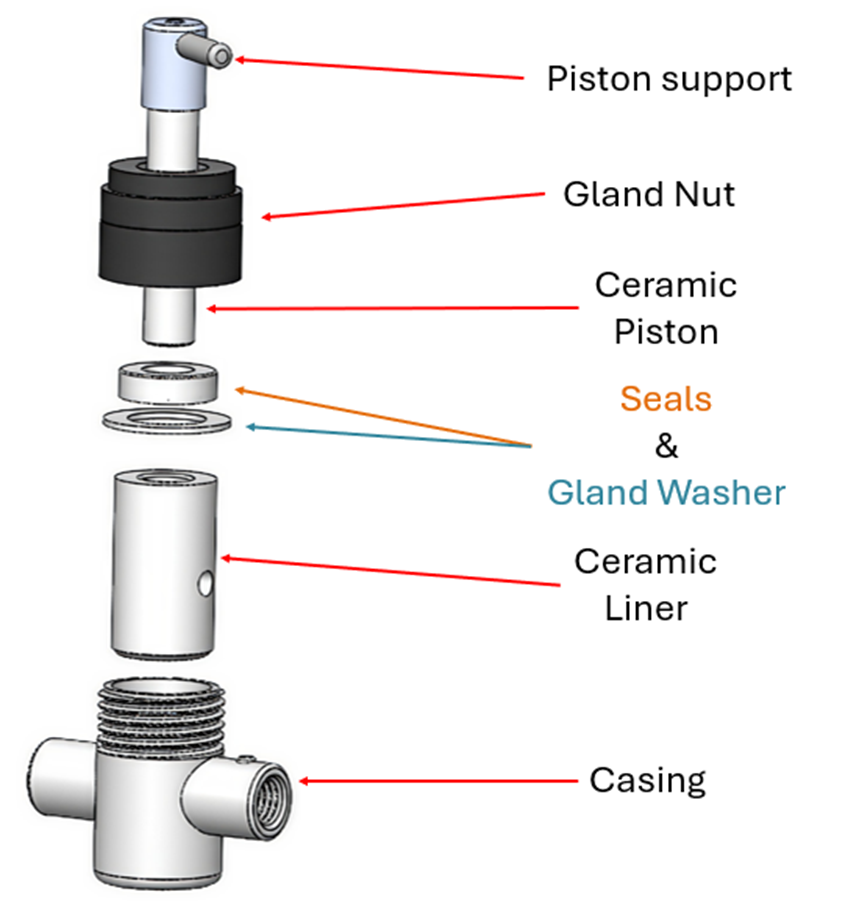

(CeramPump® exploded view showing ceramic wetted path components (piston, seal, ceramic liner, and cylinder case)

As the diagram shows, the fluid contacts ceramic components throughout its path—piston, ceramic liner, and casing. This architecture maintains material consistency across the entire flow path.

Beyond the ceramic internals, CeramPump® assemblies can be configured with different casing materials to match your system requirements:

Choose stainless steel when you need mechanical robustness, higher pressure capability, or integration with metal-based laboratory systems. Stainless housings provide structural strength and durability in demanding environments.

Polypropylene may be preferred where chemical resistance, reduced weight, or compatibility with polymer-based fluid systems is important. It's widely used in analytical and environmental applications—and often selected in systems where fluoropolymers are being avoided.

Cylinder case selection is typically driven by mechanical, chemical, and integration factors rather than direct fluid contact alone.

Sealing is critical in precision pumping, especially where leak mitigation and long-term reliability are priorities.

CeramPump® offers two part seal configurations for PFAS related consideration:

Seal selection should be evaluated based on your specific pressure requirements, fluid properties, duty cycle, and system-level risk considerations.

CeramPump® technology delivers controlled, repeatable fluid delivery across low-flow applications—exactly what's needed in PFAS-related sampling, metering, or dosing systems where volumetric consistency matters.

As with any precision pumping solution, actual performance depends on operating conditions, fluid properties, and how the pump integrates into your complete system. But the foundation—predictable, repeatable flow—is built into the design.

PFAS-related applications in medical device systems often involve long development timelines and extended service lifecycles. That's why many OEMs prioritize pump solutions that offer:

CeramPump® technology is commonly integrated into OEM systems where customization, consistency, and long-term support are critical design considerations. Material and configuration choices are evaluated as part of your broader system-level risk management process—not as isolated component decisions.

Pump selection for PFAS-related applications isn't about aggressive performance claims. It's about material compatibility, consistency, and reliability you can defend during regulatory review.

FMI's CeramPump® provides a configurable solution built around ceramic wetted components, selectable housing materials, and proven sealing technologies. As with any fluid-handling component, suitability depends on your specific system requirements, operating conditions, and applicable regulatory considerations.

Questions about material selection for your PFAS-related application? Our application engineering team can help you evaluate pump configurations and material options for your specific system requirements.

Careful material selection and system-level evaluation remain key elements of effective pump integration. Let's discuss how CeramPump® might fit your next-generation system.

Key Takeaways: Fluid Metering’s viscosity-tolerant precision pumps maintain accuracy across a wide range of fluid viscosities by optimizing tubing...

1 min read

Key Takeaways: Fluid Metering’s high-viscosity fluid pump solutions support thick, slow-moving liquids by using larger tubing, low RPM operation,...

2 min read

Key Takeaways: In heated fluid dispensing for medical applications, warming fluids improves sterility, drug absorption, viscosity control, and...