Impact of Air and How to Evacuate it From a Fluidic System

Key Takeaways: In precision microfluidic dispensing systems, trapped air can cause wide variation in dispense volumes and compromise...

2 min read

Colin Rademacher : 9/2/25 10:38 AM

Key Takeaways:

Fast-Track OEM Projects: Pump Validation and Testing for Engineers.

As mechanical and systems engineers, you're often leading new product development at OEMs, constantly challenged to optimize design cycles while ensuring performance and reliability in real-world conditions. Product testing and validation, especially for critical components like pumps, is essential, but it can also become a significant resource bottleneck.

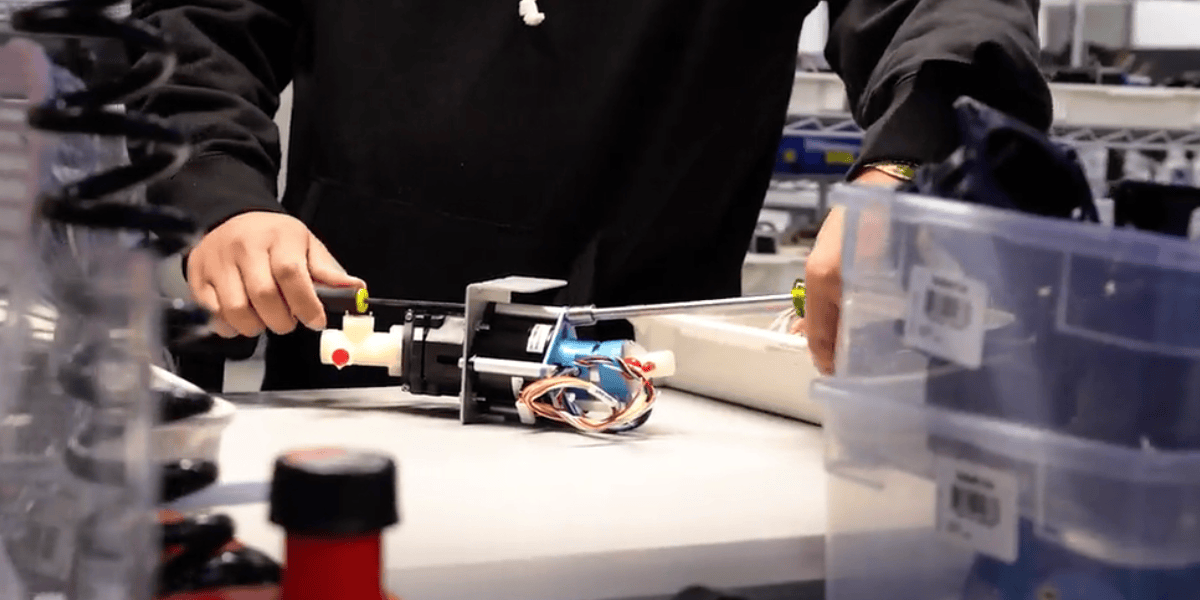

Streamline Your Development with Our Application Lab Services

We understand the pressures of product releases and regulatory demands. That's why our application lab is designed to offload your pump testing and validation workload, freeing your core team to concentrate on design iteration, simulation, and integration. Whether you need early-phase feasibility data or full-scale life cycle validation, we offer the technical infrastructure and expertise to deliver actionable, trustworthy results.

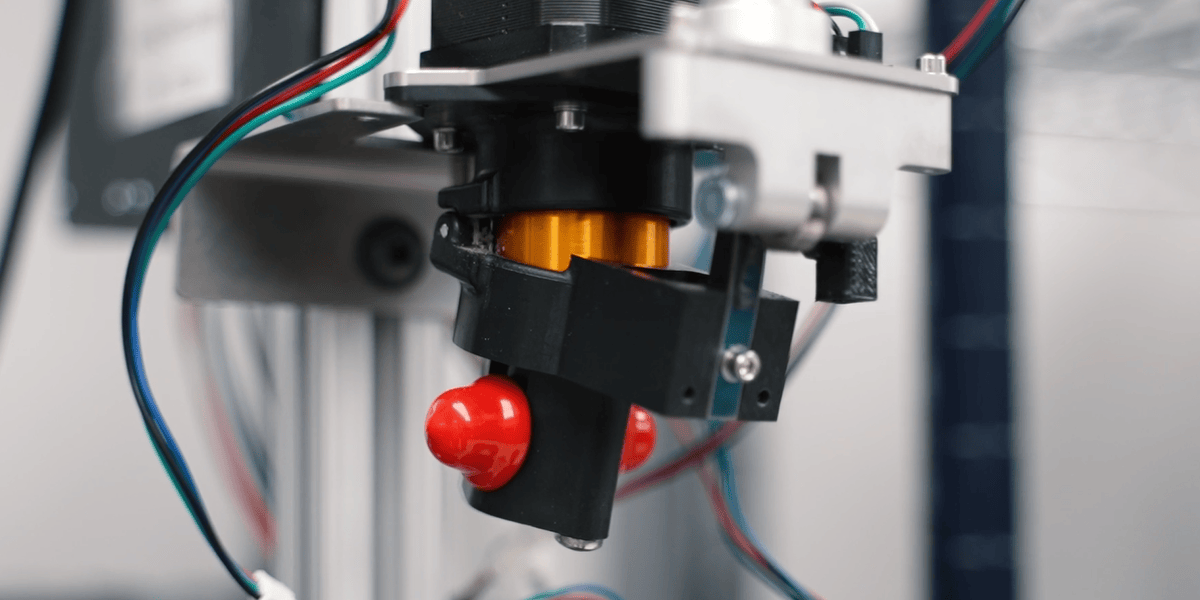

By leveraging your supplier (us!) to conduct testing, you can significantly accelerate your development cycle through rapid iteration. Immediate access to our application lab means that if an issue is detected, corrective actions and a second round of prototypes can be developed and tested without delay, thanks to our close proximity to the manufacturing cell. Our 3D printers further streamline this process by enabling fast creation of custom components and fitment parts, ensuring physical compatibility before moving forward in production.

Fluid Metering Capabilities for Mechanical and Systems Engineers

We provide a comprehensive environment to validate pump and system robustness for your OEM product needs:

Flow meters: 0–600 mL/min, resolution ±0.001 mL/min

Programmable controllers: Run complex, custom test protocols for automated test cycles, step changes, or real-time failure detection.

Precision pressure regulators for accurate boundary condition control.

Pan balances: Sensitivity down to 0.00002 g for gravimetric loss/gain tracking.

Advanced System Simulation:

With our auxiliary pump system, we can inject air bubbles into fluid lines to replicate and troubleshoot challenges associated with bubble ingress in your application.

Additionally, we can simulate backpressure scenarios and replicate water hammer effects.

Accelerated Life Cycle Testing: The Engineering Approach

Accelerated life testing is a key methodology for mechanical and systems engineers, allowing you to predict long-term reliability without waiting for real-time field data. We leverage industry-standard models to deliver reliable estimates of mean time to failure (MTTF) and support robust design decisions.

Why Partner with Us?

Reduce development cycle times with turnkey, scalable validation testing.

Leverage experienced technical staff for custom test design and rapid troubleshooting.

Access test data, failure analyses, and engineering reports to support regulatory and customer documentation.

We're dedicated to supporting mechanical and systems engineers with the resources and expertise needed to keep your projects on-track and within spec. Let's discuss your next pump validation or accelerated testing challenge—and help you reclaim critical engineering time for innovation.

Key Takeaways: In precision microfluidic dispensing systems, trapped air can cause wide variation in dispense volumes and compromise...

1 min read

Key Takeaways: Fluid Metering’s OEM pump integration solutions support stepper and DC motor configurations, enabling flexible control via...

1 min read

Key Takeaways: Fluid Metering’s Duplex pump systems for multi-fluid metering allow engineers to dispense two different fluids at independently...